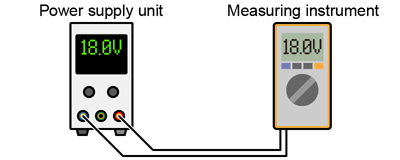

Calibration is the process of checking the performance of a measuring instrument.

The Japanese Industrial Standard (JIS) Z 8103:2000, "Measurement Terminology," defines calibration as an operation that establishes the relationship between the value indicated by a measuring instrument and the corresponding value realized by a standard, under specified conditions.

Over time and with use, an instrument's performance can drift, leading to discrepancies between the true value and the measured value. This is known as instrumental error. For example, the readings of a scale or gravimeter can be affected by its geographical location (latitude and altitude).

Such errors will have many negative impacts, including deterioration in measurement reliability, high ratio of defective products, control failures, etc.

To ensure consistently accurate results, measuring instruments must be calibrated periodically. For instruments in continuous use, this calibration should be performed at regular, specified intervals.

The required calibration interval depends on factors such as the instrument's frequency of use, operating environment, and required accuracy. Calibration is strictly a verification of an instrument's current performance against a standard. If a significant discrepancy is found, subsequent adjustment or maintenance will be required. It is important to note that calibration itself is distinct from the acts of adjustment, repair, or maintenance.

Related Technical Articles

- What is a Power Supply? Types and Applications

- What is a Power Supply? (Basic Knowledge)

- Safety and Usage of High Voltage Power Supply

- An Introduction to DC Power Supplies

- What is a Bipolar Power Supply? (Basic Knowledge)

- Electronic Loads: An Introduction to Principles, Types, and Uses

- What is an AC Power Source? - Basic Knowledge -

- Linear vs. Switching Power Supplies: Key Differences Explained

- Types of X-ray Tubes and High-voltage Power Supplies

- High Voltage Measurement Method

- How to Choose a DC Power Supply: Key Points to Consider

- Difference between DC power and AC power

- A Beginner's Guide to Using Power Supplies Safely

- A Guide to Using DC Power Supplies Correctly and Safely

- HVPS for Lab Analyzers: Key Considerations for Stability and Noise

- Amplifier Basics: Principles, Operation, and Key Considerations

- Method of Generating Direct Current (DC) Power