What are Linear and Switching Power Supplies?

Linear and switching power supplies are devices that convert electrical energy to provide a stable direct current (DC) output. A linear power supply achieves this by first stepping down the voltage of an incoming alternating current (AC) using a transformer, then rectifying and smoothing it. In contrast, a switching power supply first rectifies and smooths the incoming AC voltage, then regulates it by converting it into a high-frequency pulse train, which is then stepped down and rectified again.

Mechanisms of Linear and Switching Power Supplies

Both linear and switching power supplies provide a stable direct current (DC).

DC is used in the circuits of most electronic devices, such as smartphones, computers, air conditioners, and factory robots. Since different electronic devices and their internal circuits require various voltage levels, a DC power source appropriate for each specific voltage is necessary.

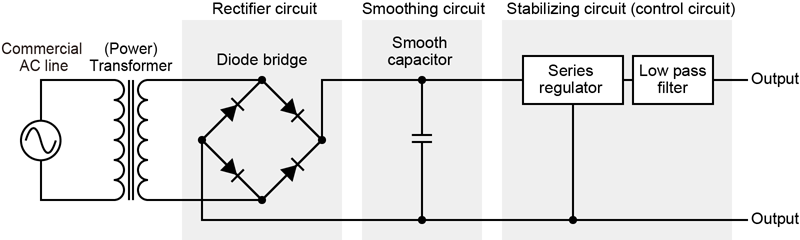

The linear power supply was developed first. Linear power supplies are also known as series regulators or series-pass power supplies. In a linear power supply, a transformer, typically consisting of an iron core and coils, is used to step down the incoming alternating current (AC) voltage. This stepped-down AC voltage is then rectified by diodes in a rectifier circuit and smoothed by a capacitor in a filter circuit to produce a DC voltage.

The voltage output from the rectifier circuit is a pulsating DC (a series of positive peaks of a sine wave), which is not yet a stable DC suitable for most electronic circuits. Therefore, this voltage is further smoothed using a filter circuit (often a capacitor) and then regulated by a stabilizing circuit (control circuit) to maintain a constant output voltage. The control circuit in a linear regulator is typically a series pass element (like a transistor) controlled by an error amplifier. Shunt regulators are another type but less common for general power supplies. This circuit monitors the output DC voltage and adjusts the series pass element to maintain a constant output level. The voltage difference between the input and output across the series pass element, multiplied by the load current, results in power dissipation as heat, often requiring a large heat sink.

Traditionally, linear power supplies required an AC transformer specifically designed for the desired input voltage, output voltage, and power rating. This meant that each power supply had fixed parameters and often required a custom transformer for each specific application.

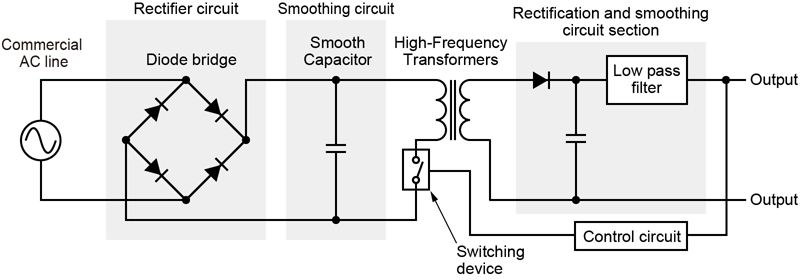

In contrast, switching power supplies first rectify and smooth the incoming AC voltage to produce a high-voltage DC. This high-voltage DC is then fed to a chopper circuit (switching transistor) that converts it into a high-frequency AC or pulsed DC. By rapidly switching a transistor on and off, this DC is chopped into a high-frequency waveform (effectively a pseudo-AC or pulsed DC), which can then be stepped down by a smaller, lighter high-frequency transformer, and finally rectified and filtered to produce the desired DC output voltage.

Comparison of Linear and Switching Power Supplies

Key differences between linear and switching power supplies include output noise levels and physical size. As mentioned, switching power supplies operate by rapidly turning a switch on and off. This switching action inherently generates electromagnetic noise (EMI). Linear power supplies, lacking this high-frequency switching, inherently produce significantly less output noise.

For instance, comparing specific Matsusada Precision models with similar output capabilities, the (R4G18-2) linear power supply has a specified noise of 0.5 mVrms (voltage) and 1 mArms (current). In contrast, the (R4K18-2) switching power supply has specifications around 5 mVrms (voltage) and 5 mArms (current).

This illustrates that, in this specific comparison, the switching power supply exhibits approximately ten times the voltage noise and five times the current noise of its linear counterpart.

Next, let's consider the physical size of the power supplies. Linear power supplies are generally larger, while switching power supplies are more compact. This size difference is primarily due to the transformer, as high-frequency transformers can be much smaller and lighter. For a given power handling capability, transformers operating at higher frequencies can be significantly smaller and lighter than those operating at mains frequency (e.g., 50/60 Hz).

In a linear power supply, the transformer operates directly at the input line frequency (e.g., 50/60 Hz). In a switching power supply, the AC input is first rectified to DC, then chopped at a high frequency (tens or hundreds of kilohertz), and this high-frequency AC is then fed to a much smaller transformer. Consequently, the transformer in a switching power supply can be significantly smaller.

For example, a power supply that can output a DC voltage of 18 V, the linear power supply (R4G18-2) measures 124 × 84 × 325 mm (H × W × D) and weighs approximately 3 kg. In contrast, the switching power supply (R4K18-2) measures 124 × 35 × 128 mm (H × W × D) and weighs approximately 500 g.

While both models share the same height in this example, the linear power supply is approximately 2.4 times wider, 2.5 times deeper, and weighs about six times more than the switching power supply. This significant weight difference is largely due to the bulky iron-core transformer required in the linear design.

Switching power supplies became widely adopted much later than linear power supplies, gaining mainstream traction around the 1990s. Older AC adapters were often bulky and heavy because they were based on linear power supply technology.

More recently, advancements like Gallium Nitride (GaN) power semiconductors have enabled further improvements in switching power supply efficiency and power density, leading to even smaller designs with lower energy losses.

GaN is a semiconductor material, similar to conventional silicon, but with properties that allow for higher efficiency and switching frequencies. Transistors built with GaN exhibit lower switching losses and can operate at higher temperatures compared to traditional silicon transistors.

These technological advancements continue to drive the development of smaller, lighter, and more efficient switching power supplies.

Other Key Differences

Beyond noise and size, several other factors differentiate linear and switching power supplies:

- ●Higher Efficiency (Lower Energy Conversion Losses) in Switching Power Supplies

-

Switching power supplies were initially driven by applications like those at NASA, where high energy efficiency was paramount for space missions. Switching power supplies are generally more efficient (typically 70-95%) because the main switching element operates either fully ON or fully OFF, minimizing resistive losses. Linear power supplies, where the pass transistor operates in its linear region, dissipate more energy as heat, resulting in lower efficiency (typically 30-60%).

- ●Faster Transient Response in Linear Power Supplies

-

Linear power supplies generally offer a faster transient response (how quickly the output voltage recovers from sudden changes in load current). This is because their control loops are simpler and do not involve the inherent delays associated with the switching frequencies and filtering found in switching power supplies.

- ●Cost Considerations: Linear for Low Power, Switching for High Power

-

For low-power applications, linear power supplies can be less expensive due to their simpler circuit design and fewer components. However, as power levels increase, the lower efficiency of linear supplies leads to significant heat generation, requiring larger heatsinks and potentially cooling fans, which increases their cost and size.

Consequently, for higher power requirements, switching power supplies often become the more cost-effective solution due to their higher efficiency and smaller component sizes (especially magnetics and heatsinks). As a general guideline, linear power supplies might be more cost-effective for applications below approximately 20-50 W. For higher power levels, switching supplies usually offer a better overall cost.

The key differences between linear and switching power supplies are summarized in the table below:

| Linear power supply | Switching power supply | |

|---|---|---|

| Output Noise (Ripple & Noise) | Small | Large |

| Circuit Complexity | Simple | Complex |

| Size and Weight | Big and heavy | Small and light |

| Efficiency | Low | High |

| Heat Dissipation | Large | Small |

| Transient Response | Fast | Slightly slower |

| Cost-Effectiveness | Generally more cost-effective for low power applications | Generally more cost-effective for high power applications |

Related Technical Articles

Recommended products

Matsusada Precision offers both linear regulator-type DC power supplies and switching-type DC power supplies based on the application.