Classification of Laboratory Analyzers and Power Supply

Here, we introduce the topic of power supply to various laboratory analyzers such as scientific instruments. There are some common parts according to the analyzers while they have different parts as well.

First, the analyzers can be broadly classified as follows:

- Electrochemical analyzers

- Optical analyzers

- Electromagnetic analyzers

- Separation analyzers

- Thermal analyzers and thermal measurement devices

- Other measurement devices and analyzers

1. Electrochemical analyzers consist of two types of devices. One device measures the amount of electricity flow (potentiometric titrators and pH meters). The other detects and measures fluorescence with a photodiode, such as fluorescent residual oxygen meters.

2. Optical analyzers and electromagnetic analyzers essentially measure electromagnetic waves and electron beams (or secondary X-rays generated by electron beams) with photodiodes.

3. Separation analyzers, thermal analyzers/thermal measurement devices, and other measurement devices/analyzers are divided into those that measure fluorescence and light absorption with photodiodes and those that measure stress and thermal conductivity with current values, similar to electrochemical analyzers. Once the pertinent values are detected as current or voltage variation, they are converted to digital data using A/D conversion. Therefore, removing the noise components such as voltage noise and ripple effects has been a major concern.

We focus on equipment that detects light (electron waves) from a light source with a photodiode, which requires more stable power supplies.

Common to these analyzers is the presence of a radiation source. All of these devices use a radiation source, and analysis is performed by detecting the transmitted and reflected light. While there are many sources, such as electron beams, X-rays, lasers, ultraviolet (ultraviolet light), visible spectrum light, and infrared (infrared light), depending on the device, the crucial factor is that the radiation source is stable. Variations in brightness (intensity) can cause errors in recording changes. To stabilize the radiation source, the power supply must also be stable. If the power supply is unstable or ripples appear, deterioration of the observation accuracy results.

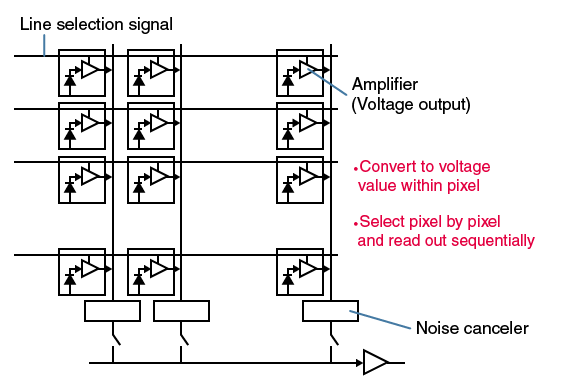

Furthermore, stability is also required in the detectors. Photomultiplier tube (PMT), avalanche photodiode (APD), and photodiodes such as PIN, CCD, and CMOS also convert charges based on the energy and number of photons received by the device into voltage. Therefore, if the power supply is not stable during this voltage conversion, the observation results, such as resolution, would be adversely affected.

Denoising

To stabilize the power supply and obtain a measurement result with a small error margin, the following aspects need to be considered:

- Thermal noise

- Leakage magnetic field

- Electromagnetic interference (EMI)

First, we consider the effects of thermal noise. Thermal noise refers to noise generated by irregular thermal vibrations of free electrons in circuit elements, such as resistors and transistors, due to external thermal energy. Regardless of the magnitude of the voltage, the noise increases in proportion to the absolute temperature. Therefore, an effective countermeasure is "circuit cooling". Incidentally, thermal noise is also called Johnson noise or Johnson Nyquist noise, after the names of the researchers John Johnson and Harry Nyquist who discovered this phenomenon in 1927.

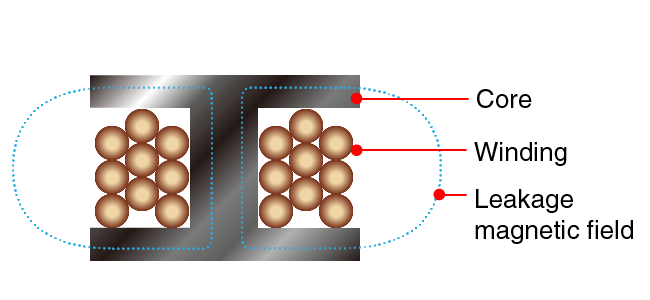

Leakage magnetic field is generated when the magnetic field created by the winding (coil) inside the power supply leaks to the external surroundings.

Open magnetic circuit structure

Unshielded

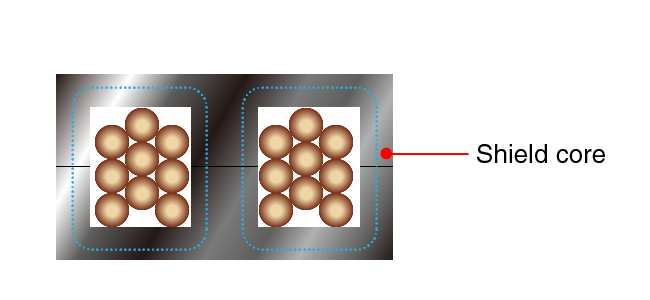

Closed magnetic circuit structure

Fully-shielded

The magnetic flux returns to the shield core, reducing the leakage magnetic field.

As shown in the figure, this can be improved by creating a closed magnetic circuit structure by using a resin shield, full shield, or integrally molded metal. It is desirable to design equipment that does not place a power supply near the radiation source or detector. If compact equipment, which is easily affected by magnetic fields, is placed near the power supply, it is necessary to incorporate a closed magnetic circuit structure.

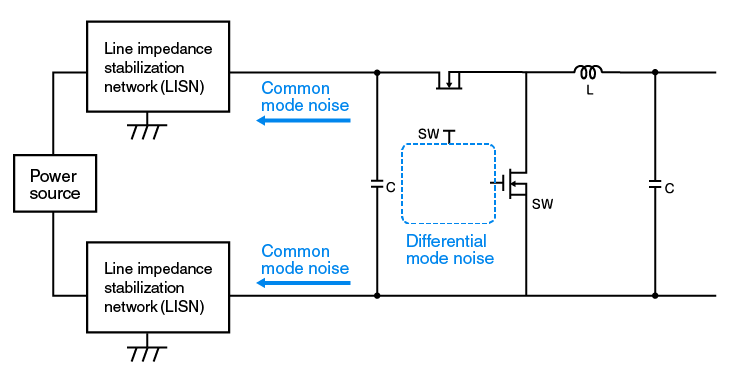

Electromagnetic interference (EMI) can be broadly divided into "radiation noise" and "conduction noise". In the former, electromagnetic waves are emitted, and in the latter, noise flows through the electrical circuit. For radiated noise, it is necessary to block the spatial conduction of noise. To do so, an object is shielded with a good conductor (or magnetic material) such as metal. In contrast, conduction noise is classified into differential mode noise and common mode noise.

Common mode noise is a component of switching noise that remains even if the loop is optimized. The noise is conducted onto the power supply and causes instability. As a result, the signal from the detector is buried in noise and cannot be measured. When the noise enters, the resolution of the analysis deteriorates, and the waveform shifts, distorts, and ghost peaks appear.

Common mode noise is noise in which the leaked noise current returns to the power line via the ground. This is called "common mode" because the direction of the noise current is the same for both the positive and negative electrodes of the power supply.

As a countermeasure, noise can be effectively confined by inserting a high-impedance component, such as an inductor, into the conducting line. Common mode noise also emits radiated noise. As the electric field strength is proportional to the cable length, it is important to use as short a cable as possible while simultaneously applying shielding.

Additionally, when installing the power supply to the analyzers, it is also necessary to consider the temperature, humidity, and chemical corrosion. Higher temperatures must be avoided as they can cause thermal noise; therefore, the power supply must not be excessively hot. Humidity also causes short circuits in the internal circuit owing to dew condensation, and corrosion not only damages the circuit but also causes unexpected errors such as the generation of corrosion current.

Related Technical Articles

Recommended products

Matsusada Precision manufactures high-performance high-voltage power supplies for analyzers worldwide.

References(Japanese site)

- Japanese source page 「高圧電源の選び方-分析装置編 分析装置の性能と電源性能の関係」

(https://www.matsusada.co.jp/column/hvps1.html) - 分析機器の手引き2017

(https://www.jaima.or.jp/jp/analytical/tebiki/) - 科学機器入門

(https://www.soran.net/guide/index2.html) - 東北大学大学院情報科学研究科 鏡慎吾 「イメージセンサの基礎」

http://www.ic.is.tohoku.ac.jp/~swk/lecture/ic2005/kagami_ic20050419.pdf (non-HTTPS address)