Reliability and safety are paramount in the automotive industry. X-ray inspection systems are essential for ensuring the quality of critical in-vehicle components, ranging from 100% production line inspection to detailed failure analysis.

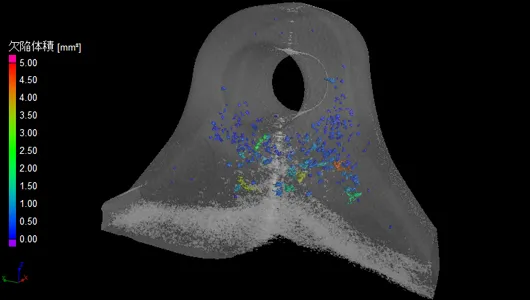

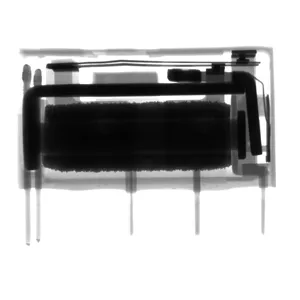

With the advancement of autonomous driving and EV technology, the number of electronic sensors and devices has increased significantly. These components must withstand harsh environments, including extreme temperatures and vibration. Matsusada Precision's X-ray inspection systems help identify internal defects--such as cracks in mounting areas or voids in molded parts--ensuring that every component meets rigorous automotive standards.

Refer to the applications below to learn more about X-ray inspection solutions for specific automotive parts.

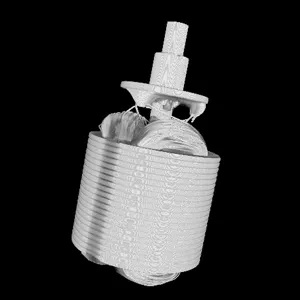

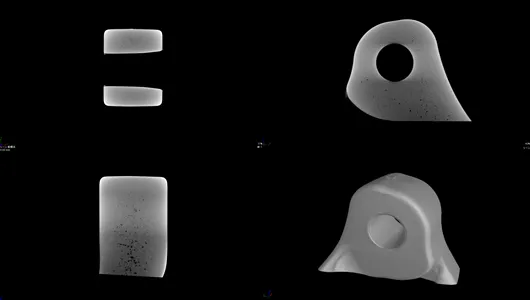

X-ray Inspection of Insert Molded Parts

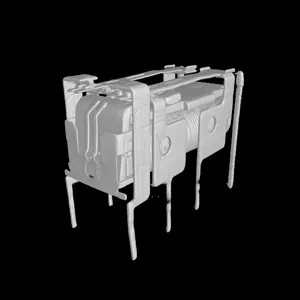

Aluminum Casting Defect Inspection

Recommended products

Related Technical Articles

- Types of Power Semiconductors -Reliability and Performance Tests

- What is a power inverter?

- Electric Vehicle Motors: Battery and Supply Voltage

- Selecting an X-ray Inspection System

- Principles of Radiography

- Safe Operation of X-ray Inspection Systems

- What is Microfocus X-ray Technology? (Basic Knowledge)

- Basics and Principles of Computed Tomography (CT)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety