X-ray inspection systems enable the non-destructive analysis of internal structures and defects invisible to the naked eye. Matsusada Precision offers a comprehensive lineup, ranging from compact, high-precision benchtop units to large-scale, high-penetration systems. The key to selecting the right model is defining your sample size and inspection objectives. Use this guide to identify the optimal system based on your specific requirements.

- Keys to Choosing an X-ray Inspection System

Select by Tube Voltage

Matsusada Precision provides X-ray inspection systems with tube voltages ranging from 20 kV to 130 kV. Tube voltage determines the penetrating power of the X-rays. Higher tube voltages generate shorter wavelengths, allowing the X-rays to penetrate denser or thicker samples. Conversely, lower tube voltages generally provide higher image contrast for low-density materials or light elements.

UP to 130kV

| Tube voltage | Focus size | Model |

|---|---|---|

| 40kV to 130kV | micro-focus X-ray tubes |

precision µX8600

precision µX8600

|

| 40kV to 130kV | micro-focus X-ray tubes |

µRay8400-LF

µRay8400-LF

|

| 40kV to 130kV | micro-focus X-ray tubes |

µRay8600

µRay8600

|

| 40kV to 130kV | micro-focus X-ray tubes |

µRay8700-LF

µRay8700-LF

|

| 40kV to 130kV | micro-focus X-ray tubes |

µRay8760-LF

µRay8760-LF

|

| 40kV to 130kV | micro-focus X-ray tubes |

precision CT9600

precision CT9600

|

| 40kV to 100kV | Mini-focus X-ray tubes |

precision µB4600-LC100

precision µB4600-LC100

|

UP to 90kV

| Tube voltage | Focus size | Model |

|---|---|---|

| 30kV to 90kV | micro-focus X-ray tubes |

precision µB3600

precision µB3600

|

| 30kV to 90kV | micro-focus X-ray tubes |

precision µX7800

precision µX7800

|

| 30kV to 90kV | micro-focus X-ray tubes |

precision µB4500

precision µB4500

|

| 30kV to 90kV | micro-focus X-ray tubes |

precision µB4600-LM90

precision µB4600-LM90

|

| 40kV to 90kV | Mini-focus X-ray tubes |

precision µB4600

precision µB4600

|

UP to 60kV

| Tube voltage | Focus size | Model |

|---|---|---|

| 30kV to 60kV | micro-focus X-ray tubes |

precision µB3200

precision µB3200

|

| 20kV to 60kV | micro-focus X-ray tubes |

precision µB4600-LM60

precision µB4600-LM60

|

| 20kV to 60kV | Mini-focus X-ray tubes |

precision µB4600-LP60

precision µB4600-LP60

|

Select by Stage Type

Select the stage configuration that best matches your sample dimensions and inspection workflow. For thorough inspection of tiny components, a compact stage ensures precision and space efficiency. For larger components or simultaneous inspection of multiple parts, a model equipped with a large-capacity stage is recommended.

XY stage

| Stage size [X x Y] | Stroke [Xs x Ys] | Model |

|---|---|---|

| 400 mm x 450 mm | 400 mm x 400 mm |

precision µX8600

precision µX8600

|

| 350 mm x 450 mm | 350 mm x 350 mm |

µRay8400-LF

µRay8400-LF

|

| 330 mm x 340 mm | 180 mm x 250 mm |

precision µB4600

precision µB4600

|

| 265 mm x 350 mm | 265 mm x 180 mm |

precision µX7800

precision µX7800

|

| 225 mm x 280 mm | 150 mm x 200 mm |

precision µB3200

precision µB3200

|

| 120 mm x 140 mm | 120 mm x 120 mm |

precision µB3600

precision µB3600

|

Turn table

| Stage size [Φ x H] | Model |

|---|---|

| 200 mm x 700 mm |

µRay8760-LF

µRay8760-LF

|

| 200 mm x 340 mm |

µRay8700-LF

µRay8700-LF

|

| 200 mm x 250 mm |

precision CT9600

precision CT9600

|

| 120 mm x 175 mm |

precision µB4500

precision µB4500

|

| Φ320 mm |

precision µX8600-LR

precision µX8600-LR

|

In addition, we offer a wealth of options for upgrading the system listed above to increase performance and make it easier to use. Our experienced staff will answer any inquiries you may have regarding non-destructive inspections using an X-ray system, as well as your intended use and desired specifications. Please contact us via the Contact page. Our staff will be happy to answer all of your questions.

Typical Applications

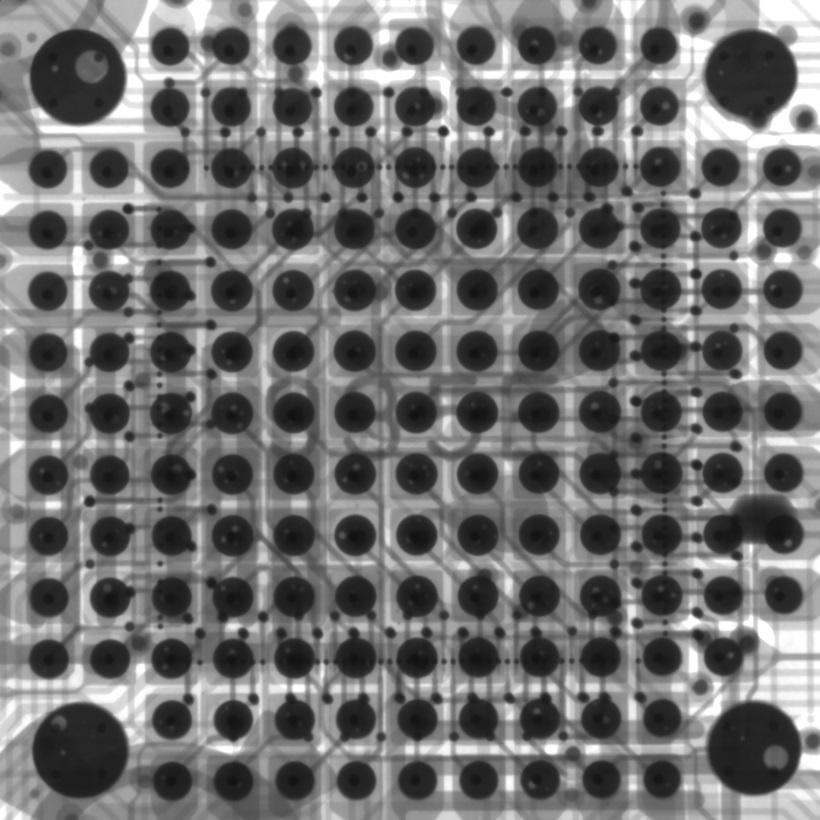

Matsusada Precision's micro-focus X-ray inspection systems are engineered for diverse non-destructive testing (NDT) applications across various industries.

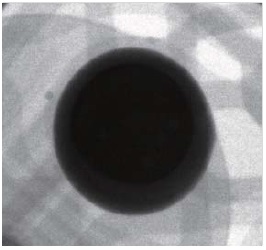

Electrical and Electronics:

Battery internal structure and metal casing inspection

BGA inspection (missing bumps, shorts)

IC wire bonding (high-magnification inspection)

Wire breaks / Open circuits

Electrolytic capacitors

BGA (Magnification inspection)

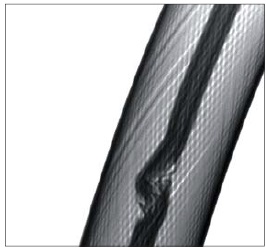

Metal Processing:

Casting voids and weld defects

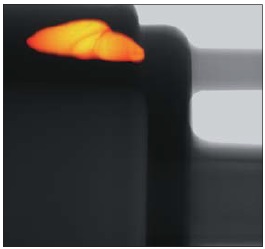

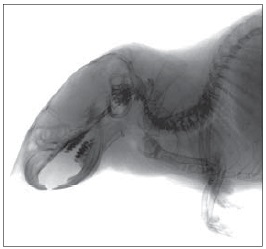

Medical and Biological Research:

Small animal imaging (bones and vasculature)

Connecting parts on product containers

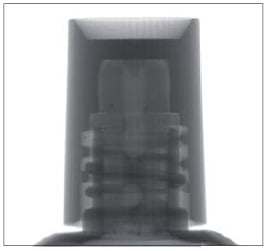

Resin and Plastic Molding:

Insert molding verification

Connectors

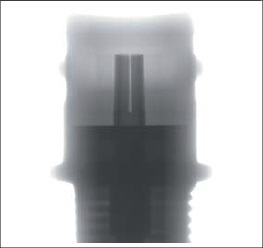

Automotive applications

Automobile components

- sensor

- valve

- oil filter

- drive shaft

- injector, etc...