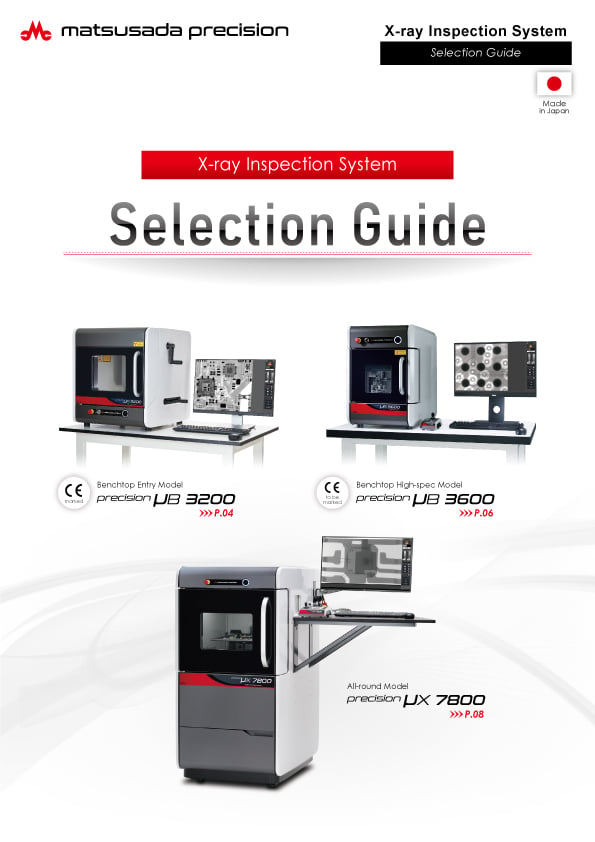

X-ray Inspection system

COMPACT & HIGH-RESOLUTION

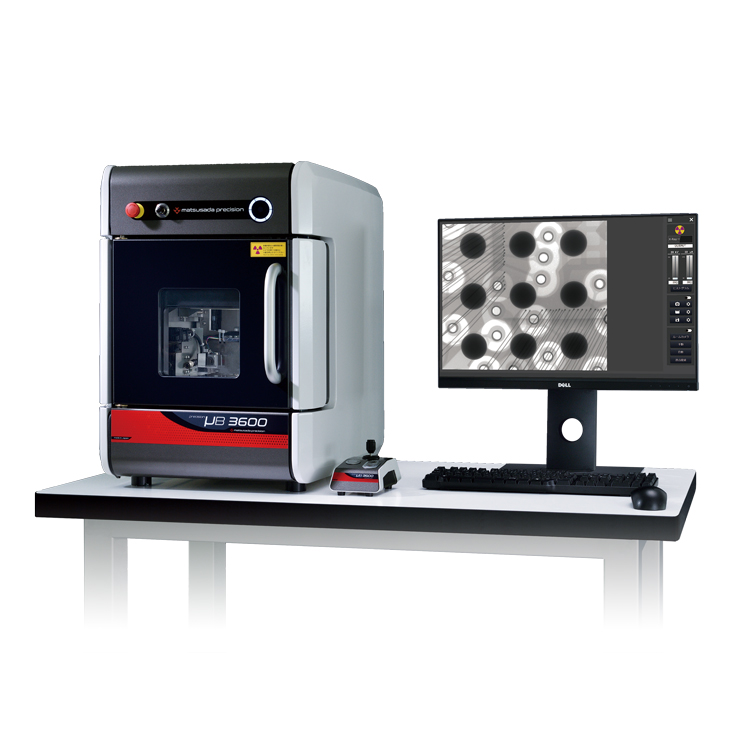

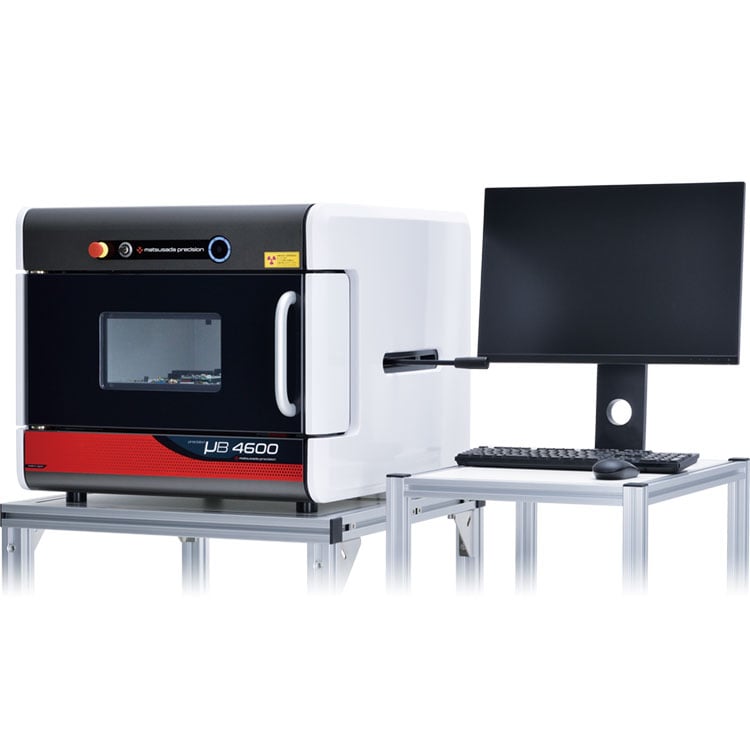

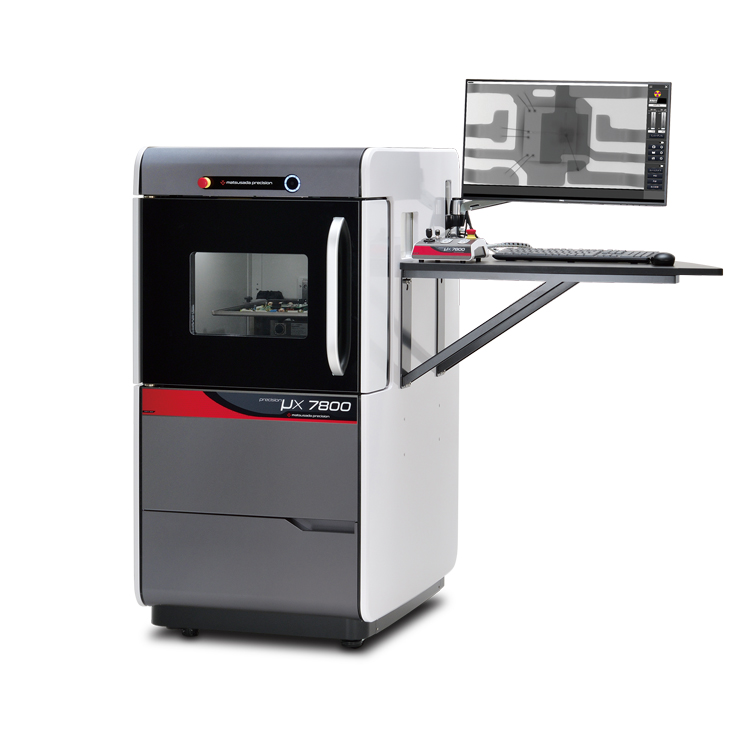

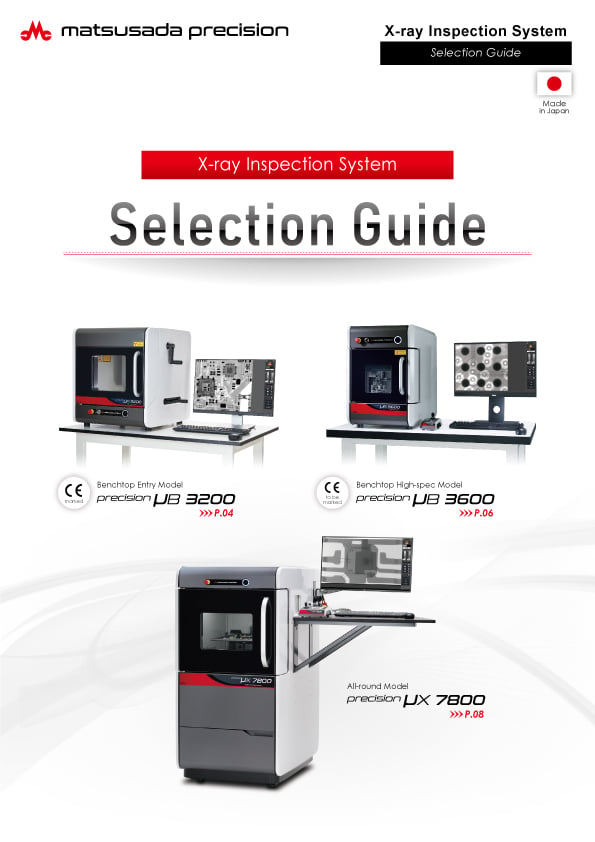

Benchtop Entry Model

- Max X-ray voltage : 60kV

- Focal spot size : 5μm

- Maximum monitor image magnification

125 times - Inspection area

2.5 × 2.8mm to 4.7 × 5.3mm

Suitable for Small Parts

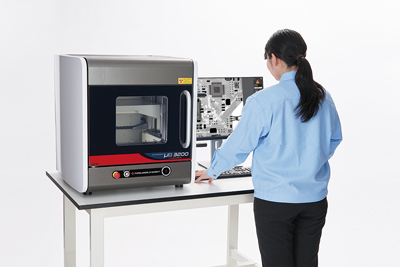

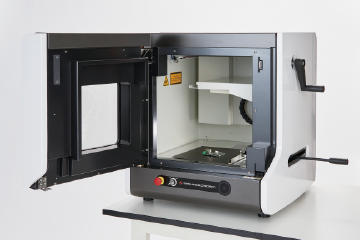

"precision μB 3200" is a benchtop entry-level X-ray inspection system. The compact X-ray inspection system fits directly on the desk to use it anywhere at small factories or offices.

And, you can adjust the geometric magnification of the sample by raising or lowering the detector position.

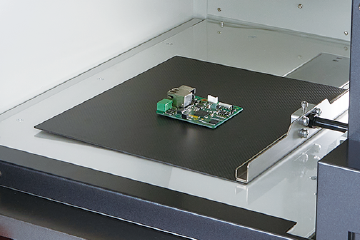

Size of Stage, Shooting Range by the Movement

The "precision μB3200" is ideal for taking images of small circuit boards and small components. For example, the maximum monitor image magnification is 125 times, the inspection area is 2.5 mm × 2.8 mm, and the applicable shooting range is 150 mm × 200 mm.

Easy Replacement

X-ray Tube Unit Replacement Steps

To replace the X-ray tube unit, remove the panels on the top and at the back side, and pull out the X-ray tube unit from the bottom part.

X-ray Detector Replacement

Slide off the detector attached to the top inside of the unit to replace it with a new one.

For the Safety

The X-ray leakage measurement we offer is conducted from all directions of each unit to confirm that it is less than 1μSv/hr before delivery.

It is the extremely low level that has no impact on the usage in daily lives.

• Safety door switch

X-rays cannot be irradiated when the door is open. If the door opens during X-ray irradiation, the Safety Door Switch function makes the X-ray emission stop.

• Product status display LED

It indicates the product status on the front panel if the X-ray irradiation is on, the door is open, and other status.

• Auto-off

If the X-ray source is mistakenly on even after the shooting is completed in the image analyzing process where you need to concentrate, using the auto-off function, you can set the time beforehand to turn off the X-ray source automatically.

• Emergency stop button

When you press the emergency stop button, the X-ray is stopped immediately.

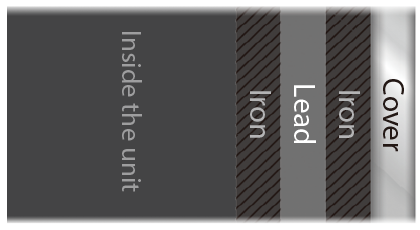

X-Ray Shielding Technology

To ensure safe and reliable installation, we have carefully designed radiation shielding.

In general, lead used for shielding is a soft and easily deformed material, but by adopting a multi-layered structure combined with steel plates, it can be used for a long time without the deformation of lead.

Model

| Model | X-ray tube | Stage | |||

|---|---|---|---|---|---|

| Anode voltage | Anode current | Focal spot size | Perimetry field | Maximum monitor magnification | |

| precision µB3200 | 30 kV to 60 kV | 150 µA MAX | 5 µm | 2.5 mm × 2.8 mm to 4.7 mm × 5.3 mm | 125 times |

Functions

Brightness adjustment

The brightness of the X-ray images can be arranged by adjusting the gain value and tone curve. Also, the automatic adjustment is available.

Contrast adjustment

The contrast of the X-ray image can be adjusted by changing the gamma value and brightness range. The automatic adjustment is also available.

Specifications

Options

- -LF3

-

CE to be markedDigital Flat Panel high resolution detector detector Gradations 16,384 (14 bits) Resolution 3 million pixels Inspection area 3.0 mm × 5.2 mm to 5.8 mm × 10.3 mm Maximum monitor magnification 103 times Monitor size 27 inches

Optical items

- XDSK320

-

Dedicated bench and control desk for precision μB3200

The settings of the optional items have high rigid structure.

- STG002/STG056

-

Height adjustment stage:

STG002 Size: 120 mm x 120 mm/STG056 Size: 120 mm x 140 mm

The stage helps you to raise its height, therefore, the sample can be closer to the x-ray detector, so you can take larger area images.

- Power Cable

-

Power cables for the product, PC, and monitor are not supplied. Please select the appropriate cable for your operating environment and region (see the table below), or prepare your own.

CABLE TYPE1 125 V/10 A CABLE TYPE8 125 V/125 A CABLE TYPE3

European Standard supported250 V/10 A CABLE TYPE4

European Standard supported250 V/10 A

Applications

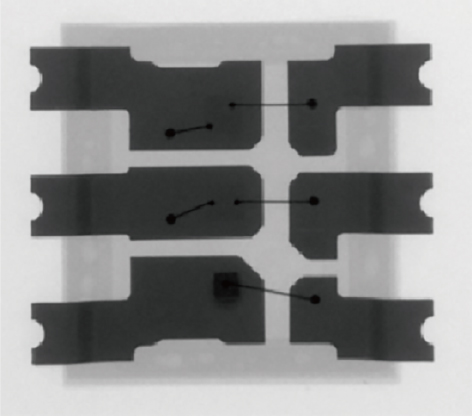

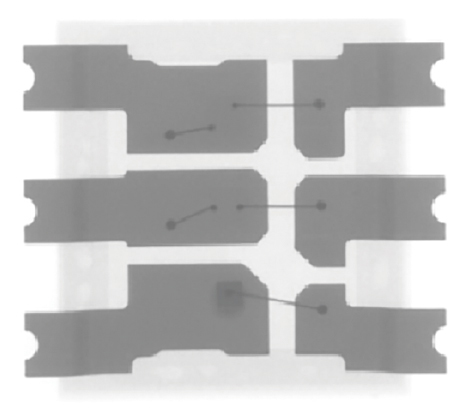

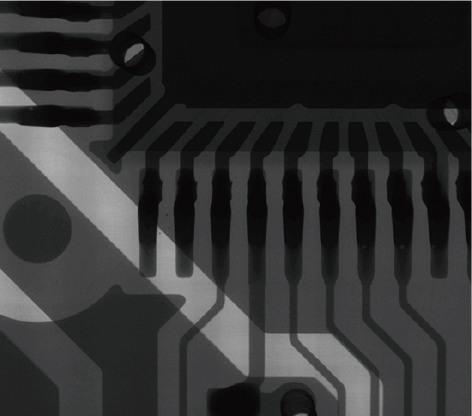

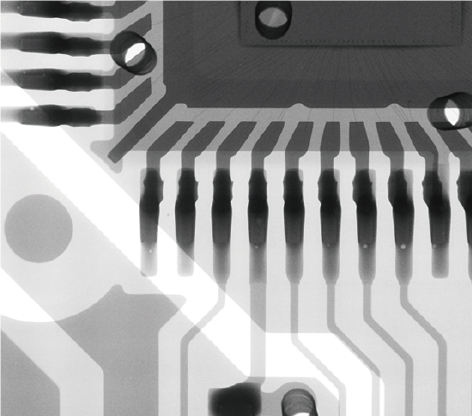

X-ray Image Galleries

Tube voltage: 60 kV

Tube current: 150 μA

Monitor image magnification: 20 times (with the optional height adjustment stage)

Tube voltage: 60 kV

Tube current: 150 μA

Monitor image magnification: 125 times

Tube voltage: 60 kV

Tube current: 150 μA

Monitor image magnification: 125 times

Fields and Applications of X-ray Radiography Non-Destructive Testing

- Pharmaceuticals and Cosmetics

Tablets, Capsules, Catheters, Medical pouches, Foreign objects in the face mask, Cosmetics

- Automobiles and Electric Vehicles

Automotive components, Wire harness, Batteries, Molded plastic parts, Motor, Insert molded parts, Aluminum die casting, Sensor, Mating parts connection

- Electronics

Ball grid array (BGA), Integrated circuit (IC) chip, Connectors, Capacitors, LED, Relays, Printed circuit board (PCB), AC adapter, Light bulbs filament, Electrical cable disconnects, Discharge traces of dielectric breakdown

- Advanced Materials

Carbon-Fiber-Reinforced Polymers (CFRP), Insulation material, Carbon, Dissimilar material joint, Contamination in beryllium

- Precision Conponents

Probe, Bearing, Mating of plastic parts, Spring position

- Creatures and Plants

Laboratory rats, Seeds, Flowers, Shell, Bone, Insects, Rice

- Others

Microscopic foreign matter contamination, Voids in welding, Plastic bottle, Sealing of cans

FAQ for performance of X-Ray Inspection System

X-Ray Inspection System FAQDownload

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

precision series Selection Guide

Date: 2023-08-09 Rev. 04

PDF (5,316 KB)

-

precision µB3200 Datasheet

Date: 2024-09-10 rev.00

PDF (3,097 KB)

Login Required

-

precision series Selection Guide

Date: 2023-08-09 Rev. 04

PDF (5,316 KB)

-

precision µB3200 Datasheet

Date: 2024-09-10 rev.00

PDF (3,097 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.