Introduction to X-Ray Computed Tomography

X-ray computed tomography is a powerful non-destructive testing technique using X-rays to obtain two-dimensional and three-dimensional images. X-ray computed tomography uses X-rays to radiate the object from many different directions and analyzes the resulting images. It is mainly characterized by reconstructing three-dimensional images.

Using the X-ray CT, the X-ray inspection system provides images of the internal structure of the part. By utilizing the X-ray radiation from one direction, the X-ray inspection system can generate two-dimensional vision images of the objects. The X-ray inspection system is commonly used for medical-purpose X-ray examination and airport baggage screening.

There are big differences between the X-ray inspection and the X-ray CT scan system: The X-ray inspection provides vision images of an object in the direction of X-ray radiation. The X-ray CT scan system provides cross-sectional images of the area radiated with X-rays to the object. The X-ray inspection system generates the X-ray direct vision images, but this is not the case with the X-ray CT scan. Tomographs that are sliced image data are converted to create a realistic three-dimensional model. The CT reconstruction can be carried out on a computer system through the CT image processing method.

Principle and Structure of X-Ray CT

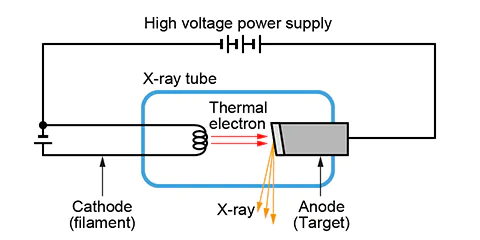

X-ray CT uses X-rays as a light source for imaging. The X-rays are also referred as "ionizing radiation". Because of its very short wavelength and large energy, the X-rays interact with atoms in the object.

As the X-rays pass through an object, they hit electrons and other particles orbiting the atoms, and then, they are attenuated. The Attenuation rate is higher for dense materials such as metals. Low-density materials such as air and paper, in contrast, have a lower attenuation rate.

In product inspections, it is possible to virtually evaluate the condition of the inside of a product, which cannot be seen from the outside using X-ray attenuation.

In addition, for the same material, if it is thicker in the direction of X-ray penetration, the attenuation rate will be higher, and if it is thinner, the attenuation rate will be lower.

This property is what determines the computed tomography quality.

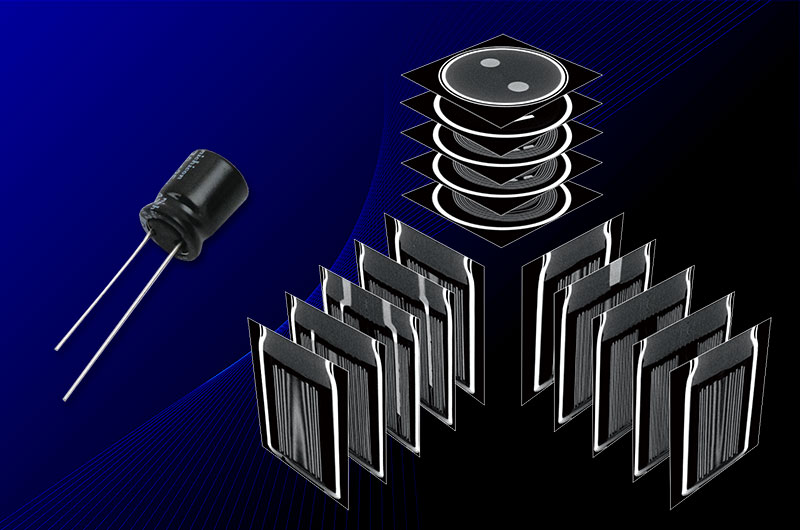

By utilizing the penetration capabilities of X-rays, the CT technology generates cross-sectional images of the object like shadow pictures or watermarked pictures for detailed analysis. X-ray images have no information on the height (thickness) direction. Data acquired with X-ray CT can be viewed from any direction and cross sections from any position.

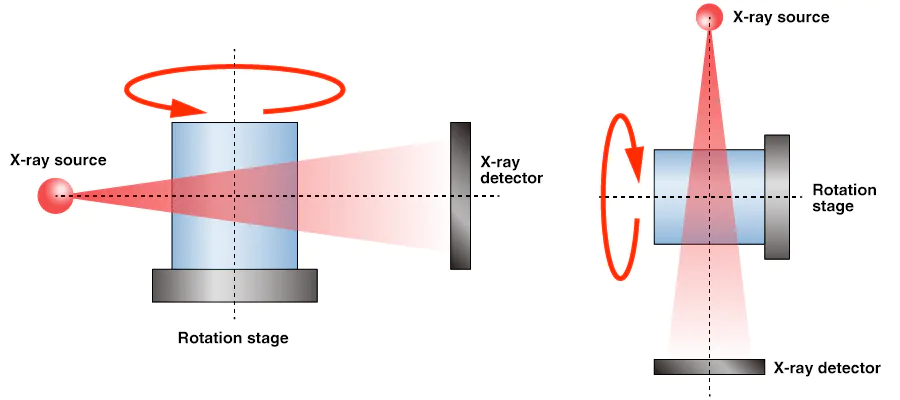

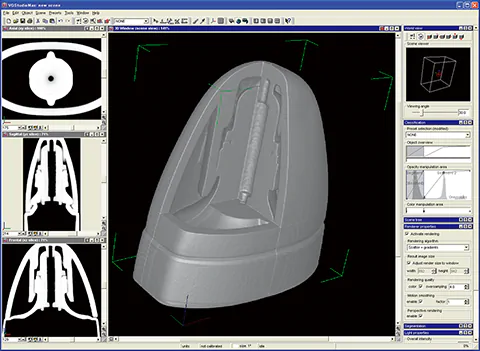

Refer to the following for the X-ray CT structure.

X-rays are emitted from the X-ray source to penetrate the object on the stage and are captured by the X-ray detector. The image of the transmitted X-rays acquired by the X-ray detector changes as the object rotates.

An elongated component on the cross-section will be displayed as small in one orientation but large at another angle. This allows CT reconstruction and output of CT image data. In order to reconstruct and analyze the correct picture, software with an appropriate reconstruction algorithm is required.

To generate X-rays, a current is first passed through the filament to heat it. The filament generates hot electrons, which are accelerated by high voltage and collide with the target of the anode.

The way computed tomography works is by hitting the object with X-ray beams from an X-ray source. As the X-ray penetrates the object, it rotates on the rotation stage located between the digital detector panel and the X-ray radiation source. The captured images are reconstructed to develop a 3D model of the part. X-ray digital radiography detector is a Flat Panel Detector (FPD) that has two types of direct and indirect detectors.

Indirect detectors use scintillators to convert X-rays and produce visible light. The vision X-rays hit the scintillators to convert to light photons that are then detected by a photodiode (PD).

Direct detectors are based on flat panels of amorphous selenium (a-Se). A high-voltage bias is applied to the selenium film, and a current will flow as X-ray visions hit the film. Then, the current turns on a thin film transistor (TFT), which converts the signal into an image.

Comparison of Medical CT and industrial X-ray CT

There is a big difference between medical and industrial X-ray CT scans.

In medical X-ray CT scanning for inspection, an X-ray source and an X-ray detector move with spiral rotation around a person and take sliced images (tomographic images) to generate 360-degree images. Typically, a person cannot rotate themselves during a medical CT scan, unlike an object in an industrial CT scanner. The CT scanning method with spiral rotation is referred to as Helical CT.

Meanwhile, in industrial X-ray CT, an object under inspection rotates to produce 3D images. Industrial CT scanning generally keeps the X-ray source and detector fixed, and an object is rotated to collect tomographic images. In the industrial CT scan system, fan-beam CT and cone-beam CT scanners are used depending on the spread angle of the X-ray beam.

With fan-beam CT scanners, X-rays are spread out in a fan shape. The fan-beam CT scanner can achieve high resolution and are widely used for versatile, high-resolution CT scanning system.

In other types of cone-beam CT scanners, X-rays are spread out in a conical shape. The cone-beam CT system is popular in industrial divisions since the cone-beam scanner can reconstruct 3D volume data (slice data) with a single rotation.

The cone-beam CT scan system has different geometric shooting methods: Normal scan, Full scan, Half scan, Offset scan, Continuous scan, and Intermittent scan.

Industrial CT Applications

More and more companies in various sectors use industrial CT scanning technology. Industrial CT scanners are mainly used for applications in quality control, research and development, etc. As an example of a quality control application, the CT scanners with computed tomography offer fault solutions if cast aluminum parts fail to meet the strength condition. It can detect shrinkage cavities in casting.

Industrial CT scanning is used for non-destructive quality inspections that can check the internal structure, internal flaws, foreign matters, shrinkage cavities in casting caused by defective filling, etc. It is also available in fault investigation and reverse engineering applications.

The industrial CT scanning solution has other applications for research and development: Condition monitoring of highly functional materials such as microdevices, microstructures, Glass Fiber Reinforced Plastics (GFRPs), composite materials, polymer materials, and porous metals.

Another notable application of industrial CT scanning to non-industrial fields is archaeology.

The non-destructive inspection with the industrial CT scanning technique enables examination of the internal structure of items excavated from archaeological sites without destroying them. Micro-CT and 3D Microfocus X-ray microscopes in industrial CT applications can be used to generate high-resolution images. The products provide 3D X-ray imaging like a standard industrial and medical CT scanning system.

The industrial X-ray CT system offers an ultra-high resolution that enables detailed 3D visualization of the pores of porous ceramics.

Related Technical Articles

- Principles of Radiography

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- FAQ: What is the tube voltage or acceleration voltage necessary for X-ray inspection systems?

Recommended products

Matsusada Precision's X-ray CT Scanners can take high-definition and High-resolution images with its unique microfocus X-ray technology.