Following our previous discussion on the principles of X-ray CT, this article focuses on data formats, storage methods, and practical applications of the captured data.

File Formats for X-ray CT Images

X-ray CT data is primarily saved as image files. The process involves reconstructing tomographic images from X-ray transmission data. Since these tomographic slices are monochrome, any file format supporting monochrome raster data is suitable.

Common formats include JPEG (widely used in digital photography), RAW (uncompressed data), and TIFF, which is frequently used for high-quality monochrome images. However, the dominant standard in medical and industrial imaging is the DICOM format. An X-ray CT dataset typically consists of a stack of these tomographic images.

Understanding the DICOM Format

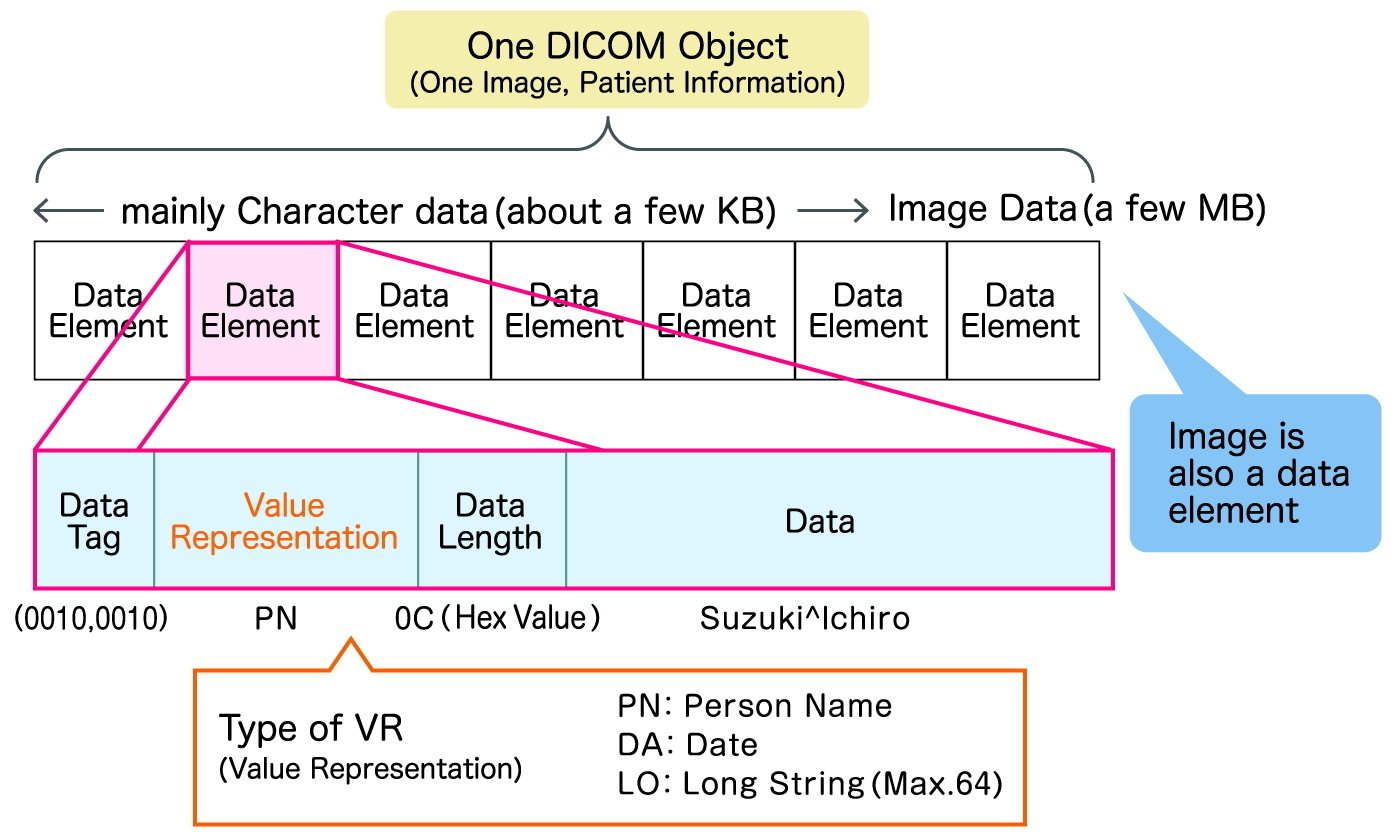

DICOM (Digital Imaging and Communications in Medicine) is the global standard for handling, storing, printing, and transmitting information in medical imaging. It ensures that images meet specific standardization requirements.

Developed jointly by the American College of Radiology (ACR) and the National Electrical Manufacturers Association (NEMA), DICOM aims to standardize image formats and communication protocols. Since its initial release in the 1980s and the establishment of the standard in 1993, DICOM has become the de facto standard for X-ray CT systems worldwide. This compatibility allows data exchange between devices from different manufacturers.

A DICOM file contains a header with metadata--such as acquisition date, patient or sample ID, and parameters--followed by the image pixel data. This structure ensures that essential information remains attached to the image data.

Within the DICOM wrapper, image data is often stored in RAW or JPEG formats. RAW format preserves all original information but results in larger file sizes. JPEG is used when file size reduction is prioritized, provided the image quality remains sufficient for analysis. Some systems also support "JPEG Lossless," a compression method that preserves data integrity, though compatibility with general viewing software may vary.

Applications of X-ray CT Data

Modern X-ray CT systems, utilizing microfocus X-ray tubes, can generate high-definition images. With advancements in computing power, processing times have decreased, expanding the range of industrial applications.

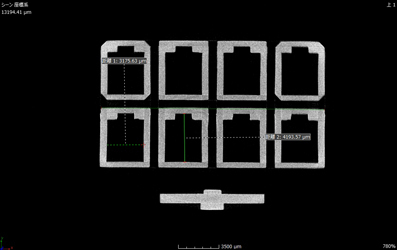

3D Visualization and Defect Detection

By stacking the obtained tomographic images sequentially, users can scroll through the internal structure of a sample, viewing it effectively as a video. This method makes it easier to identify internal defects--such as voids in castings or foreign materials--that might be missed in a single 2D image. Data can be exported as video files (AVI, MP4) for reporting and presentations.

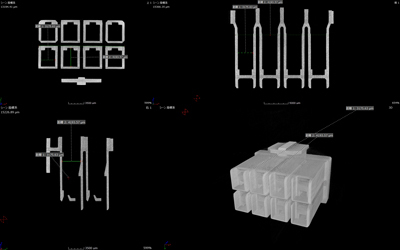

Reverse Engineering and Dimensional Measurement

A key application is reverse engineering, where the internal and external structures are reconstructed into a 3D volume model. This allows for conversion into 3D CAD data, enabling precise measurements of dimensions, volume, and density. With current technology, dimensional measurement errors can be reduced to the micrometer level.

This capability allows for "Nominal-Actual Comparison," where the scanned product is overlaid with its original design (CAD) data. By visualizing deviations from the design, manufacturers can identify manufacturing inaccuracies and improve production processes.

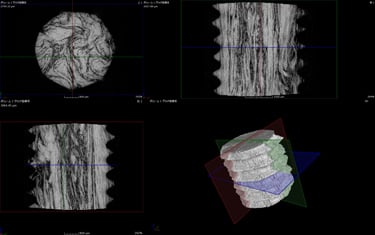

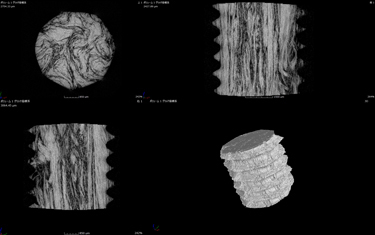

For advanced analysis, VGSTUDIO MAX by Volume Graphics is considered the industry standard for handling CT voxel data and performing Multi-Planar Reconstruction (MPR).

Non-Destructive Testing (NDT)

X-ray CT allows for the inspection of internal structures without damaging the sample. In the Fiber Reinforced Plastic (FRP) industry, fiber orientation analysis previously required destructive testing. With X-ray CT, this can be evaluated non-destructively. Similarly, in metal casting, 100% inspection for cracks and blowholes is possible, replacing sampling-based destructive methods.

Fig: Fiber orientation analysis for FRP

3D Printing Integration

Since CT data describes a 3D shape, it can be converted into STL (Stereolithography) format, the standard for 3D printing. This allows for the physical reproduction of scanned internal structures. To ensure high-quality 3D models, low-noise original data is essential.

Utilization Examples: From Industry to Medicine

Beyond reverse engineering and quality control, X-ray CT data has diverse uses. In engineering, converting scanned parts into 3D models allows for motion simulation and structural analysis (CAE) without relying solely on blueprints.

In the medical field, 3D printing from CT data enables the creation of full-scale organ models. These models assist surgeons in planning complex procedures and serve as educational tools for interns. They are also valuable for informed consent, allowing physicians to visually explain procedures and targeted areas to patients, rather than relying on verbal descriptions alone.

Virtual Reality (VR) Applications

DICOM data can also be converted into OBJ format for use in Virtual Reality (VR) environments. This technology allows users to immerse themselves within a magnified view of a sample's internal structure--whether it be a biological organ or an industrial component--providing a unique perspective for inspection and education.

As file formats standardize and processing technologies evolve, the utility of X-ray CT images continues to expand, bridging the gap between digital analysis and physical manufacturing.

Related Technical Articles

- Basics and Principles of Computed Tomography (CT)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- FAQ: What is the tube voltage or acceleration voltage necessary for X-ray inspection systems?

- Non-Destructive Testing: Types and Applications

Recommended products

Matsusada Precision's X-ray non-destructive inspection system can take high-definition and High-resolution images with its unique microfocus X-ray technology.

Reference (Japanese site)

- Japanese source page 「X線非破壊検査シリーズ② X線CT像で得られる情報とその見方」

(https://www.matsusada.co.jp/column/x-xct2.html) - 電子顕微鏡の原理

(https://www.jaima.or.jp/jp/analytical/basic/em/principle/) - 走査電子顕微鏡(SEM)の原理と応用

(https://www.jaima.or.jp/jp/analytical/basic/em/sem/) - 88年の常識を覆す画期的な電子顕微鏡を開発

(https://www.jst.go.jp/pr/announce/20190524/index.html) - 走査電子顕微鏡の原理と応用(観察,分析)

(https://www.jstage.jst.go.jp/article/jjspe/77/11/77_1021/_pdf)