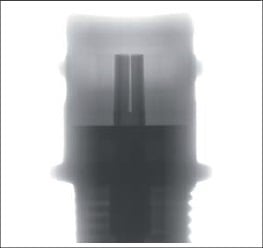

Insert molding is a method of integrally molding metal parts such as terminals by using resin or rubber. Insert molded products may look normal from the outside, but metal-to-metal contact may cause a short circuit, or voids in the resin may weaken the strength, resulting in defective products. Therefore, it is necessary to observe the inside of the object by X-ray image. Insert molded products are used in many electronic devices such as terminals, terminal blocks, connectors, switches, gears, and cases.

Such observations need high X-ray tube voltage to view the detailed metals and a high-resolution camera to inspect the shape and voids in the resin part.

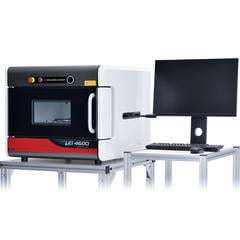

The benchtop X-ray inspection system precision μB4600 has options in terms of X-ray tube voltage and X-ray camera to meet your needs. For customers who frequently observe metals, a high-vision model with an optional X-ray tube voltage of 100 kV is available. An advanced option, models employing the tube voltage 60 kV and 3-megapixel, are provided to inspect a wider area of resin parts.

The X-ray CT-compatible inspection system, precisionμB4500, features a new artifact reduction function that enables observation of hidden areas from noise.

| Focal spot | Microfocus |

|---|---|

| X-ray tube voltage | 60 to 130 kV |

| Magnification | 1 to 100x |

Recommended products

Information on related articles in Technical Knowledge

- The Right Way to Choose appropriate X-ray Inspection System

- Principles of Radiography

- How to use X-ray Inspection System safely

- Computed Tomography (CT) Basic and Principle

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Take Beautiful X-ray CT Images? - X-ray Non-Destructive Inspection series (1) -

- How to View X-ray CT Images - X-ray Non-Destructive Inspection series (2) -

- X-ray Image Processing and Automated Inspection - X-ray Non-Destructive Inspection series (3) -

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Radiation Effects on the Human body and the safety of X-ray equipment