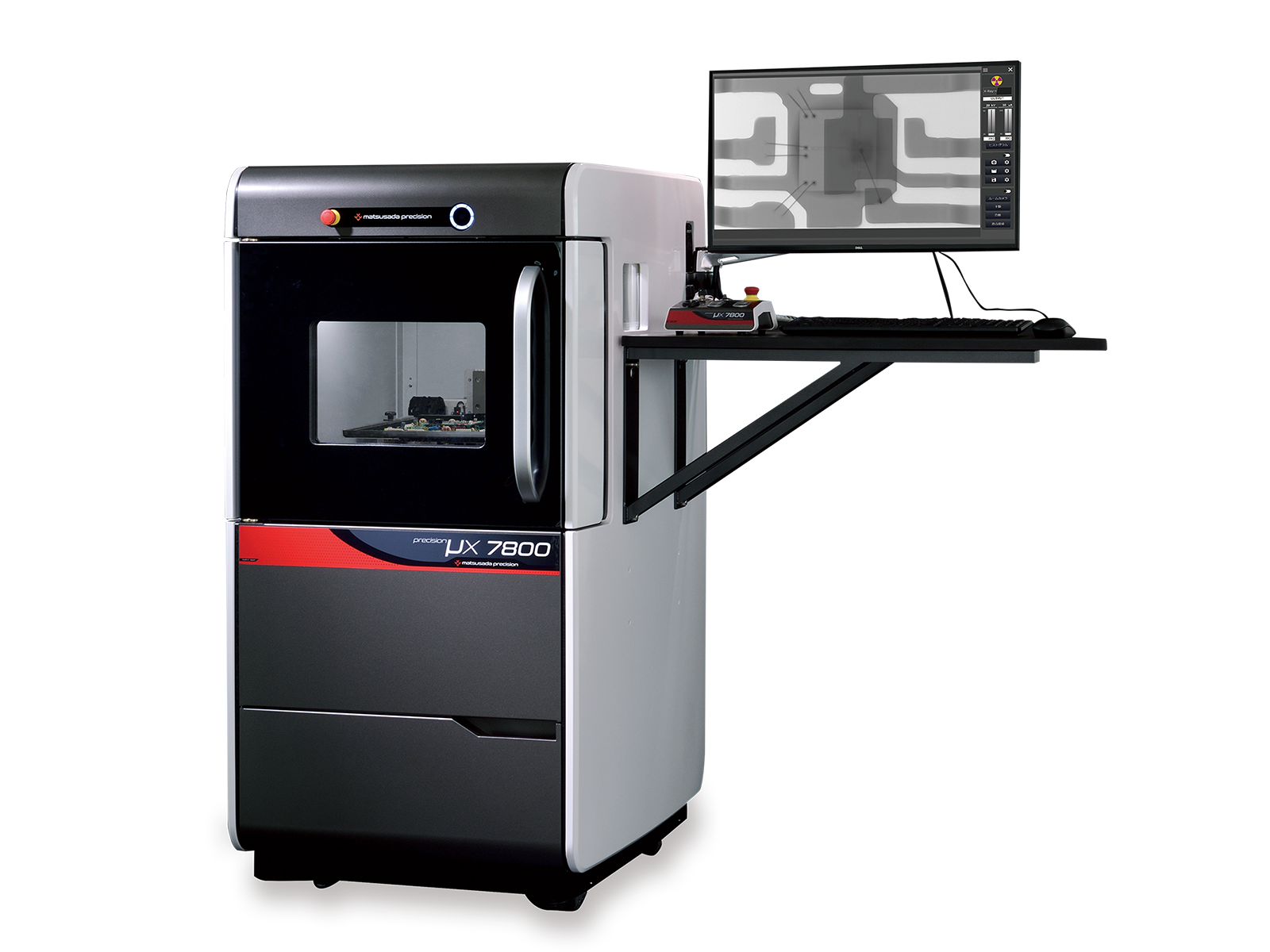

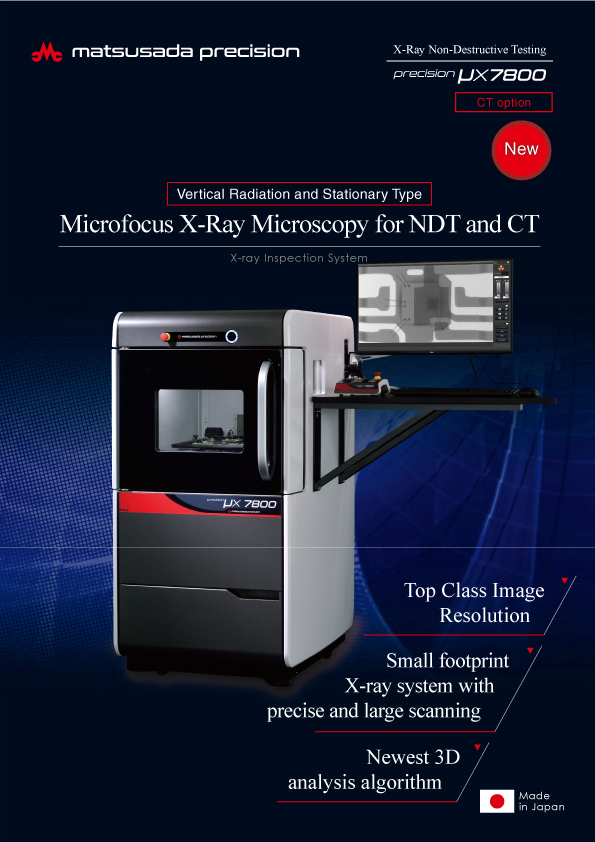

The precision µX7800 is an off-line X-ray inspection system. With a computer built into a compact chassis and a benchtop-size footprint, inspection operations for SMT and all other electronic components can be started immediately.

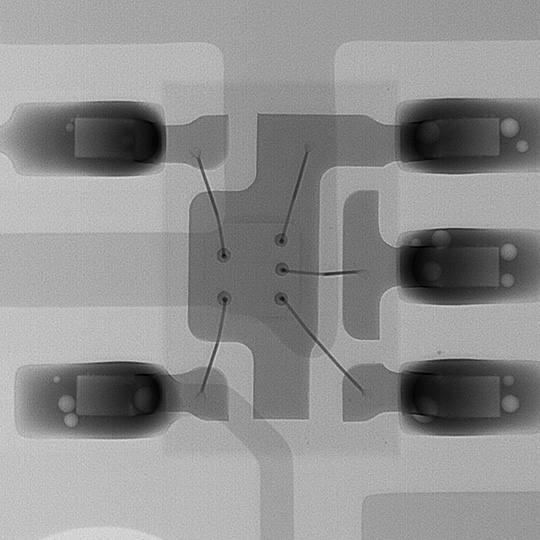

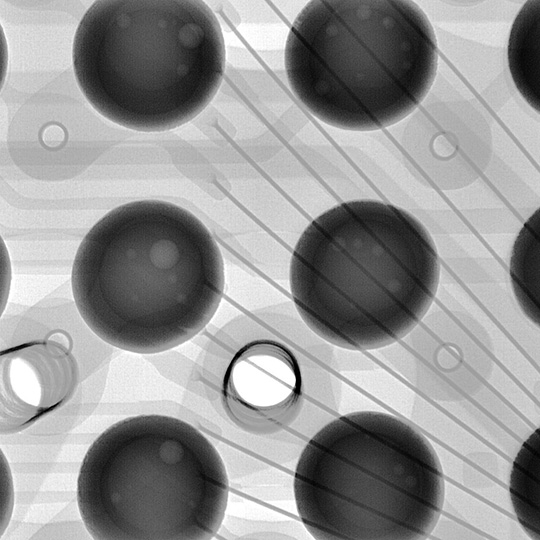

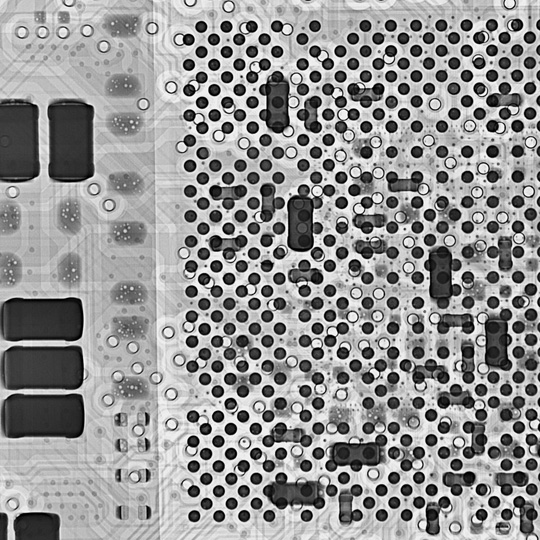

High-Resolution Imaging

The precision µX7800 delivers exceptional image clarity using a 3-megapixel camera (14-bit), advanced image processing, and a proprietary X-ray tube. By combining Matsusada’s specialized X-ray source technology with the latest HDR-Pro image processing, the system captures high-contrast images with a wide dynamic range. This ensures precise fault analysis and reliable inspection results.

Maximum field of view X: 81 mm × Y: 46 mm

Maximum CT scanning area Ø: 140 mm × L: 33 mm

Compact Footprint with Wide Scanning Area

This stationary microfocus X-ray system features a space-saving design while maintaining a high magnification capability. Despite its compact chassis, the precision µX7800 is equipped with a high-performance X-ray tube and high-voltage power supply developed in-house. This efficient design enables a large field of view (X: 81 mm × Y: 46 mm) and precise scanning, making it easy to integrate into limited workspaces without compromising performance.

Advanced 3D Analysis Algorithm

The optional CT function includes artifact reduction algorithms to ensure high-quality tomography.

Tomographic images often suffer from artifacts that degrade image quality. The precision µX7800 utilizes advanced processing to minimize these artifacts, producing clear tomographic images comparable to dedicated high-end CT systems.

* Requires -LCTDaX and -LCTDa options.

High resolution detector

Equipped with a 3-megapixel (optional 6-megapixel) detector, the precision µX7800 enables you to achieve clear images with high resolution.

New HDR-Pro image processing with high dynamic range of radiography

The radiographic images produced in HDR-Pro are available with wide and dynamic ranges. The HDR-Pro allows for a clear display without sacrificing the tones in the white or black areas.

High-quality X-ray tube developed by Matsusada

The X-ray tube in conjunction with the advanced high-voltage power supply developed by Matsusada provides the best solution for noise suppression and high-quality X-ray source. In addition, Matsusada, the high-voltage power supply manufacturer, focuses on developing new technologies and successfully designing smaller sizes of high-voltage power supplies and the X-ray system.

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

Login Required

-

precision μX7800

Date: 2025-08-19 rev 04

PDF (8,643 KB) -

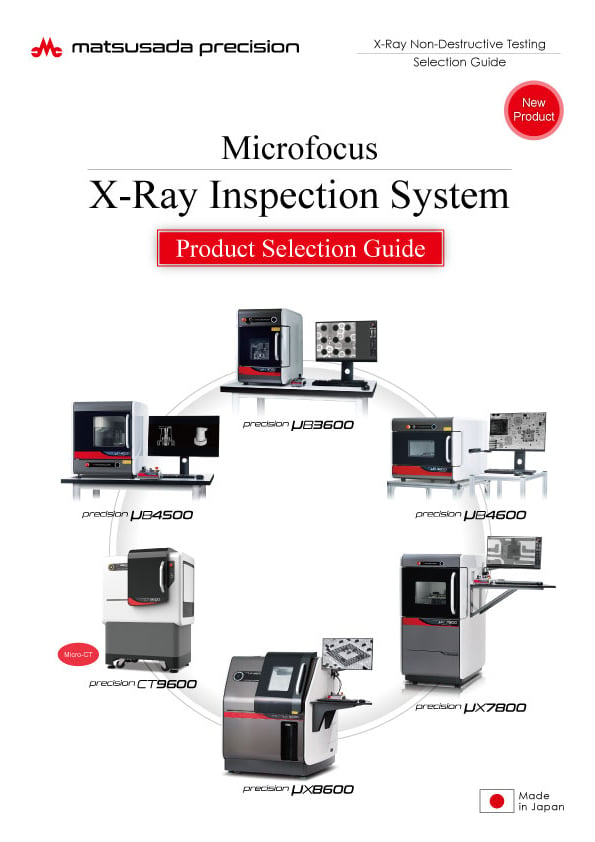

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-05-07 rev.06

PDF (13,911 KB) -

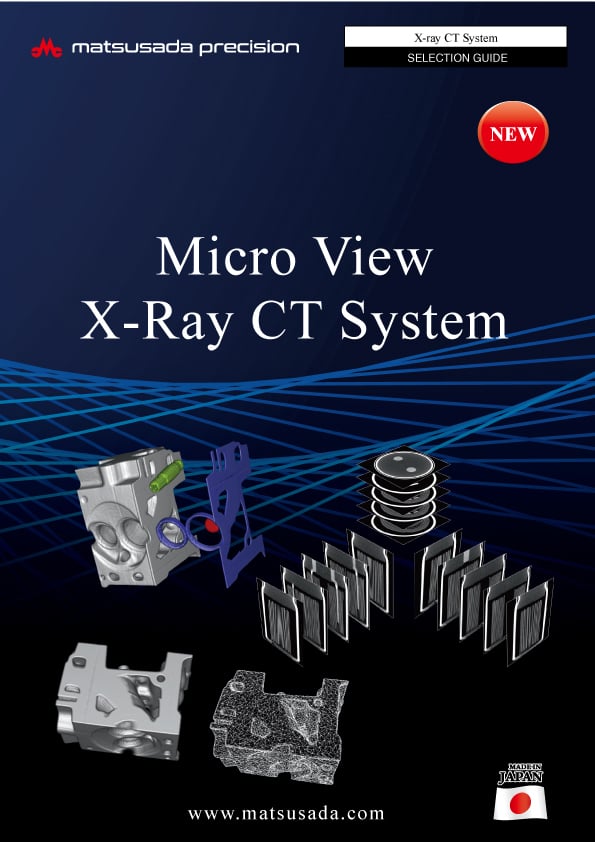

Micro View X-Ray CT System Guide

Date: 2025-09-12 Rev 08

PDF (4,989 KB)

Related Technical Articles

Similar products

-

New

precision μX8600

- X-ray tube voltage

- 130 kV

- X-ray power

- 40 W

Microfocus X-Ray Inspection SystemTop and Oblique Angle View

-

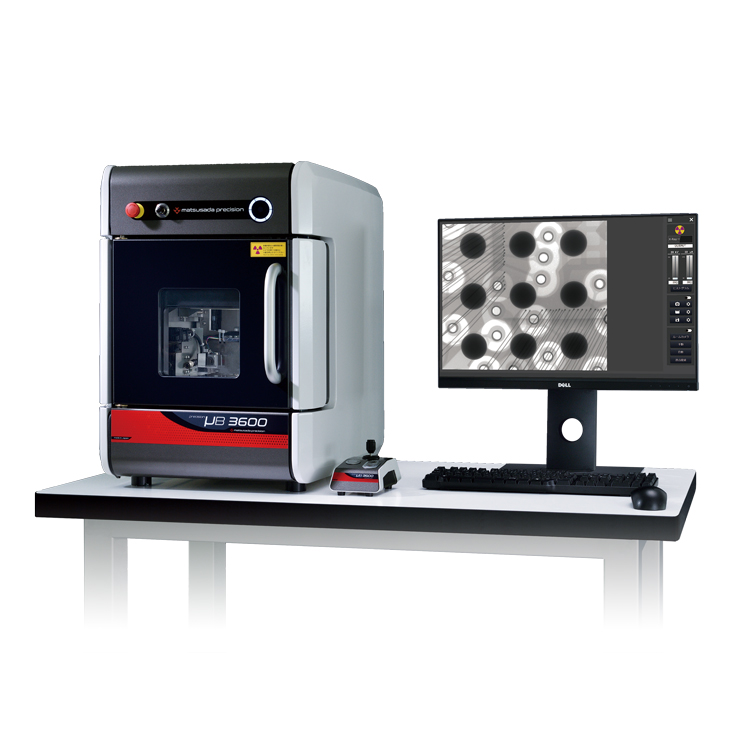

precision µB3600

- X-ray Tube Voltage

- 90 kV

- X-ray Power

- 13.5 W

X-ray Inspection SystemBenchtop High-spec Model

-

New

precision µB3200

- X-ray Tube Voltage

- 60 kV

- X-ray Power

- 9 W

X-ray Inspection SystemBenchtop Entry Model

-

New

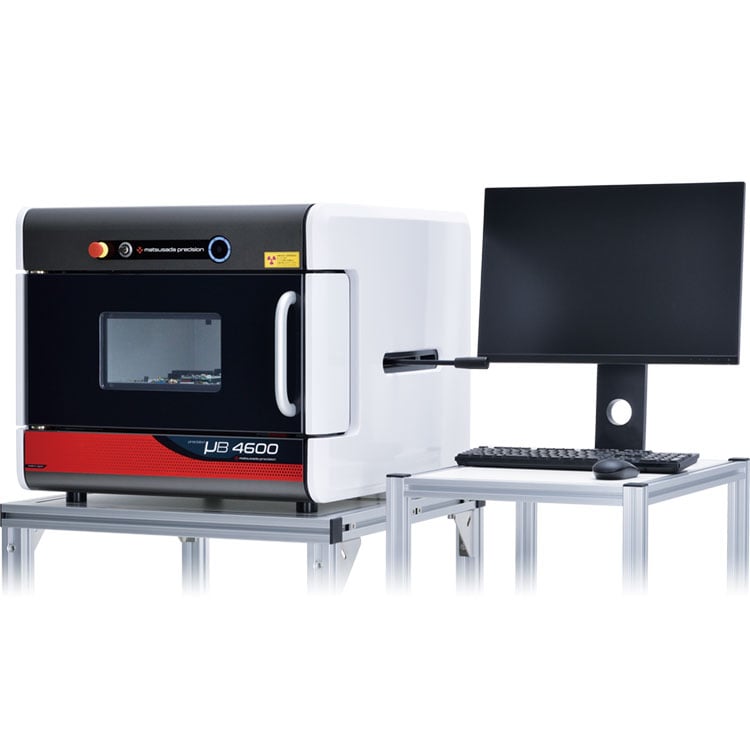

precision µB4600

- X-ray Tube Voltage

- 60 to 90 kV

- X-ray Power

- 9 to 60 W

X-ray Inspection SystemHigh Power Model

Product Lineup:

X-ray Inspection SystemsUser Support

FAQ

- What is Micro‑focus X‑ray?

- What is the tube voltage for X‑ray inspection systems?

- What is the difference between medical and industrial X‑ray systems?

- What is the difference between sintering and die‑attach in power semiconductors?

- Is a license required for usage of X‑ray inspection system?

- Can the X‑ray inspection system perform X‑ray analysis?