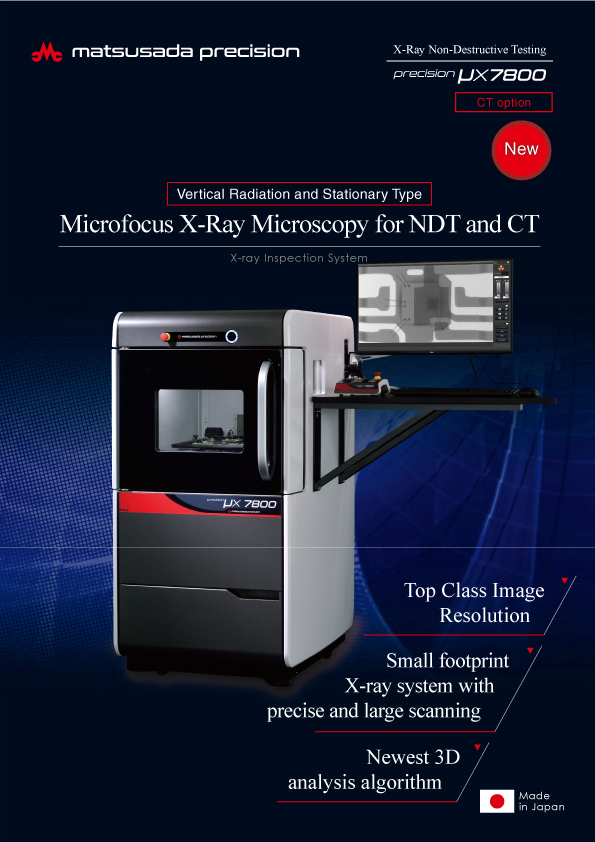

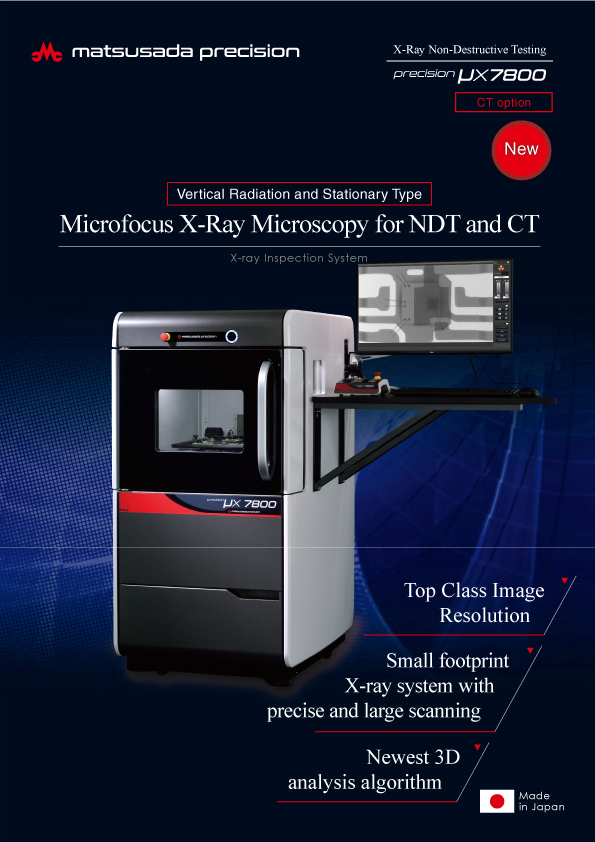

Top Class Image Resolution

The precision μX7800 offers ultimate image resolution and performance with a 3-megapixel camera, the newest image processing technics, and a high-quality X-ray tube developed by Matsusada.

With a combination of the high-resolution camera (14-bit), X-ray tube developed by Mastusada, and the latest image processing function s-HDR, the precision μX7800 enables you to obtain high-quality images with a wide dynamic range. This allows for inspection and fault analysis improvement.

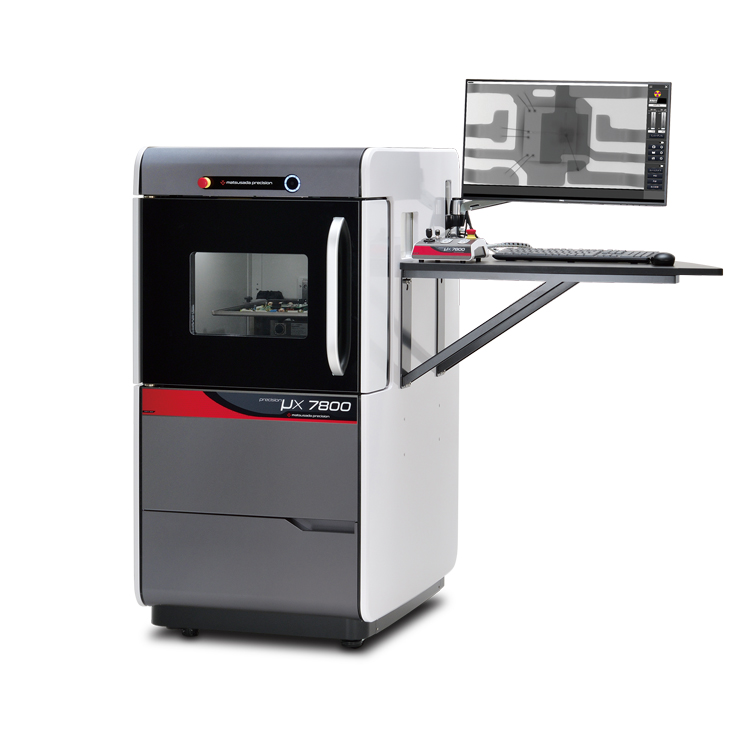

Small footprint X-ray system with precise and large scanning

The stationary type of the microfocus X-ray system provides unique capabilities with the CT industry's most compact design and a higher magnification than conventional products.

Conventional X-ray systems for high-magnification observation have been rather large with a greater distance between the X-ray tube and the camera. The precision μX7800 has a high-quality, high-voltage power supply and X-ray tube exclusively developed by Matsusada, featuring a compact design and high magnification. It enables unprecedentedly large scanning with an expanded field of view (X: 81 mm × Y: 46 mm).

Newest latest 3D analysis algorithm

CT option provides artifact reduction algorithms for exceptional tomography quality.

Tomographic images with artifacts could cause a deterioration in image quality. The precision μX7800 comes with an artifact reduction function that can obtain the tomographic images available on dedicated high-end CT systems.

* The -LCTDaX and -LCTDa options are necessary for the function.

-

High resolution detector

Equipped with a 3-megapixel (optional 6-megapixel) detector, the precision μX7800 enables you to achieve clear images with high resolution.

-

New s-HDR image processing with high dynamic range of radiography

The radiographic images produced in s-HDR are available with wide and dynamic ranges. The s-HDR allows for a clear display without sacrificing the tones in the white or black areas.

-

High-quality X-ray tube developed by Matsusada

The X-ray tube in conjunction with the advanced high-voltage power supply developed by Matsusada provides the best solution for noise suppression and high-quality X-ray source.

In addition, Matsusada, the high-voltage power supply manufacturer, focuses on developing new technologies and successfully designing smaller sizes of high-voltage power supplies and the X-ray system.

For details, download the datasheet.

Data Sheet

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

precision μX7800

Date: 2023-08-01 Rev.02

PDF (7,810 KB)

-

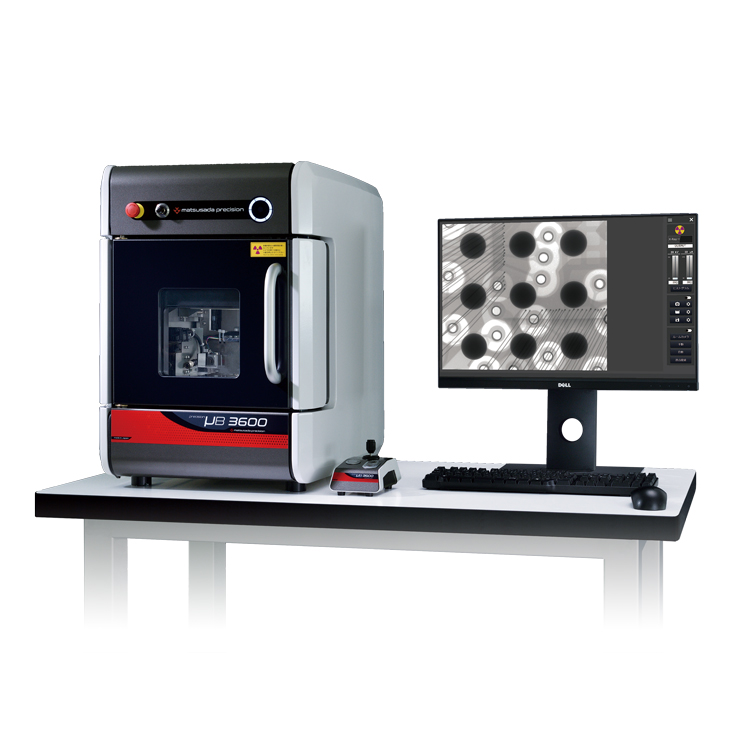

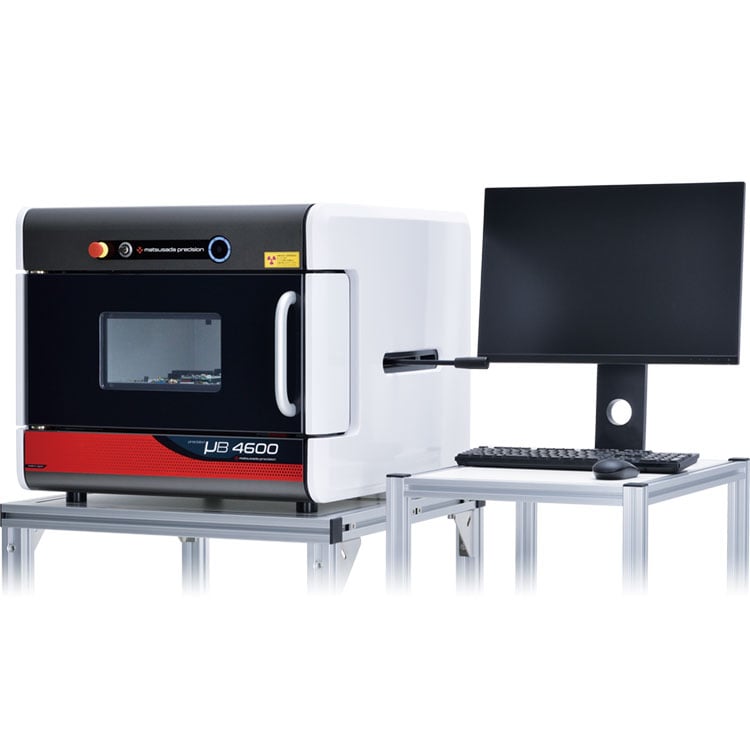

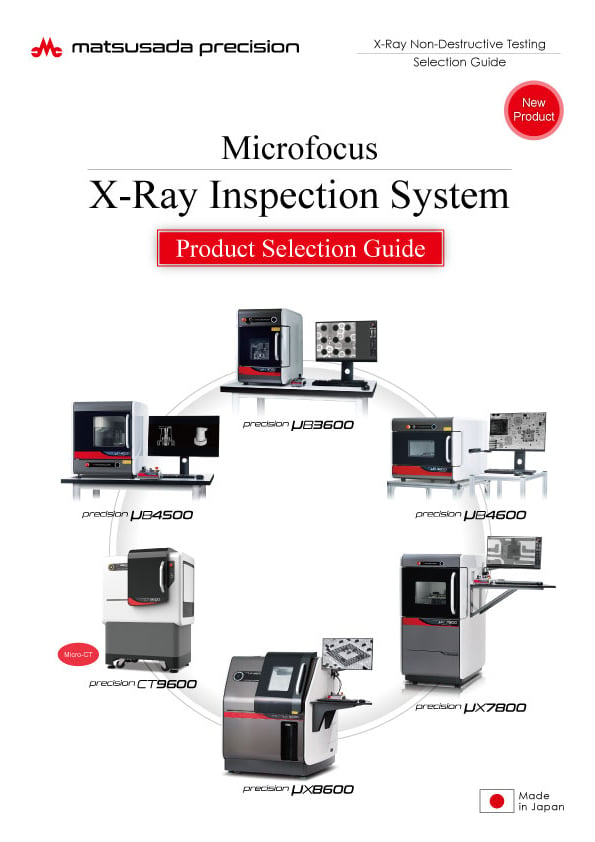

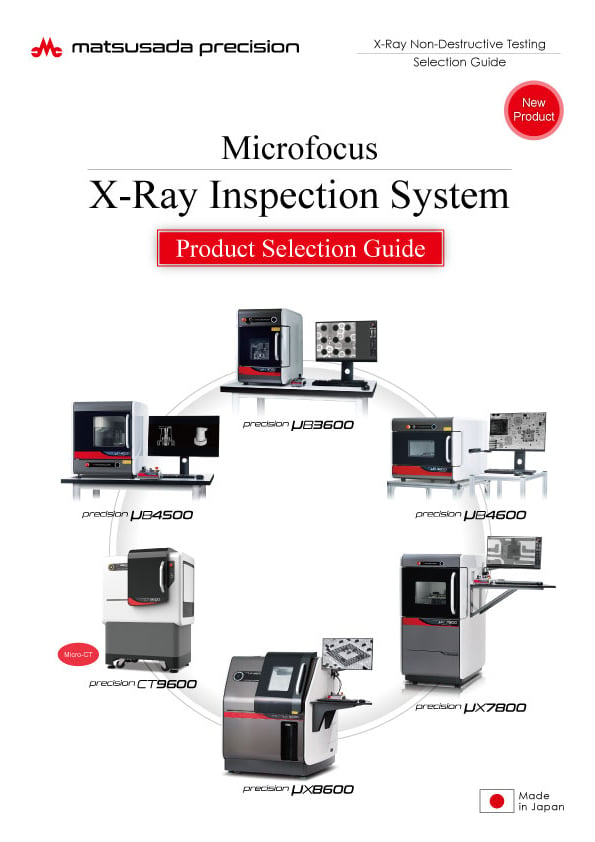

Microfocus X-Ray Inspection System

Date: 2024-01-19 rev.03

PDF (6,003 KB)

-

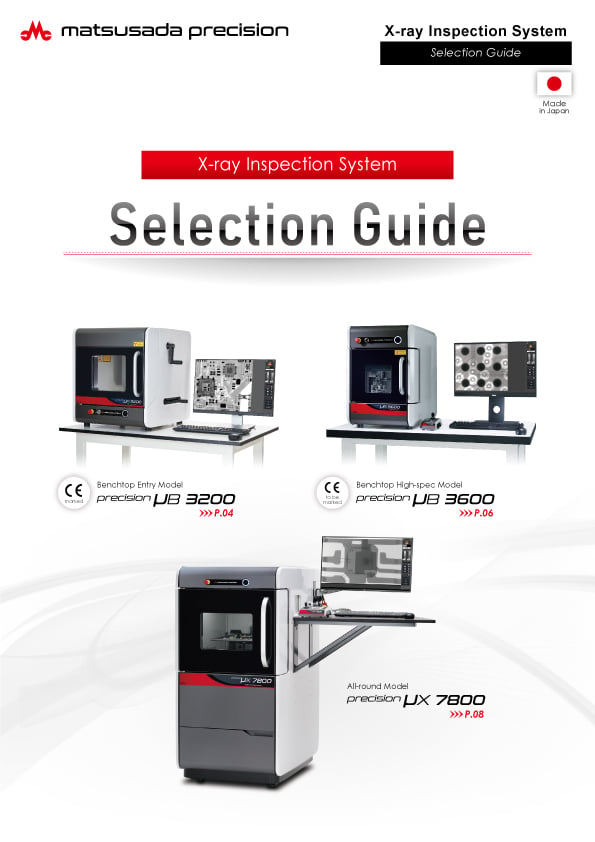

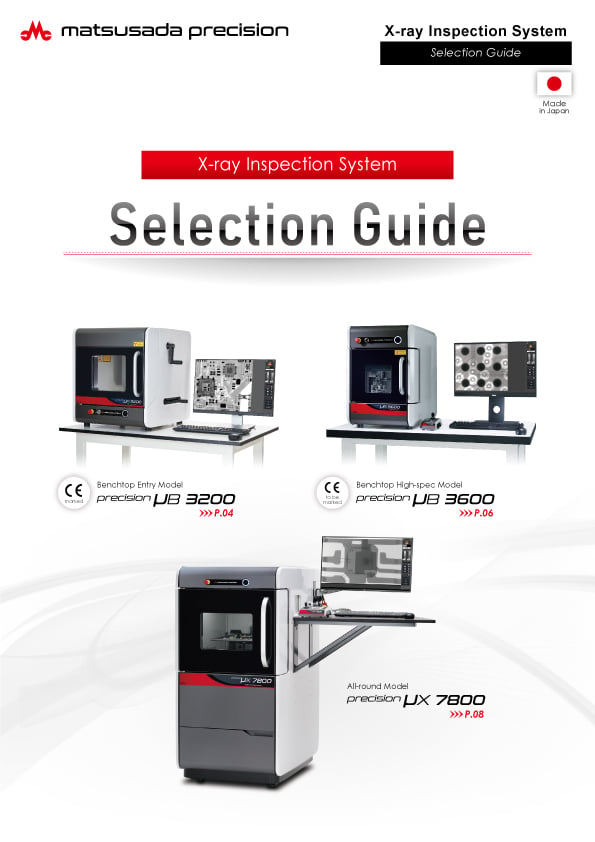

precision series Selection Guide

Date: 2023-08-09 Rev. 04

PDF (5,316 KB)

-

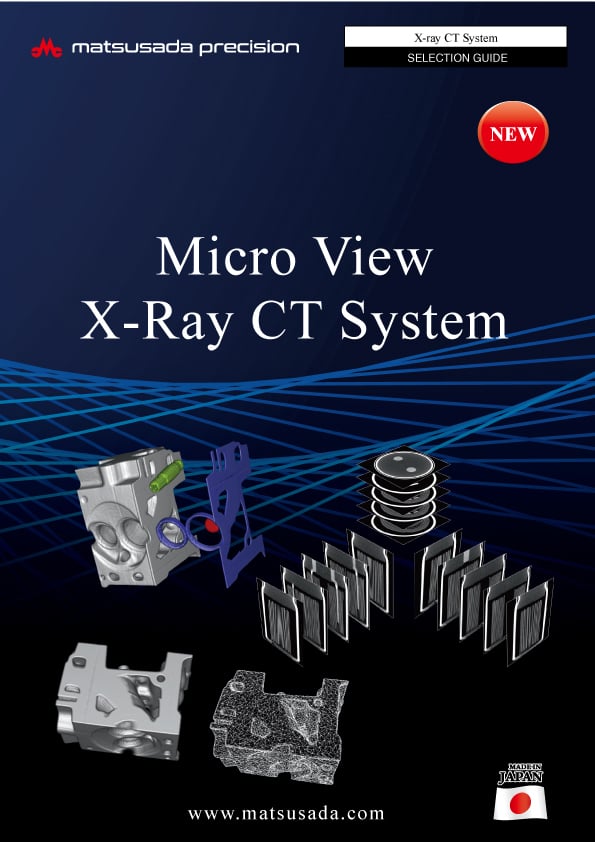

Micro View X-Ray CT System Guide

Date: 2023-08-04 Rev.04

PDF (9,169 KB)

The account registration is necessary for downloading

-

precision μX7800

Date: 2023-08-01 Rev.02

PDF (7,810 KB)

-

Microfocus X-Ray Inspection System

Date: 2024-01-19 rev.03

PDF (6,003 KB)

-

precision series Selection Guide

Date: 2023-08-09 Rev. 04

PDF (5,316 KB)

-

Micro View X-Ray CT System Guide

Date: 2023-08-04 Rev.04

PDF (9,169 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.