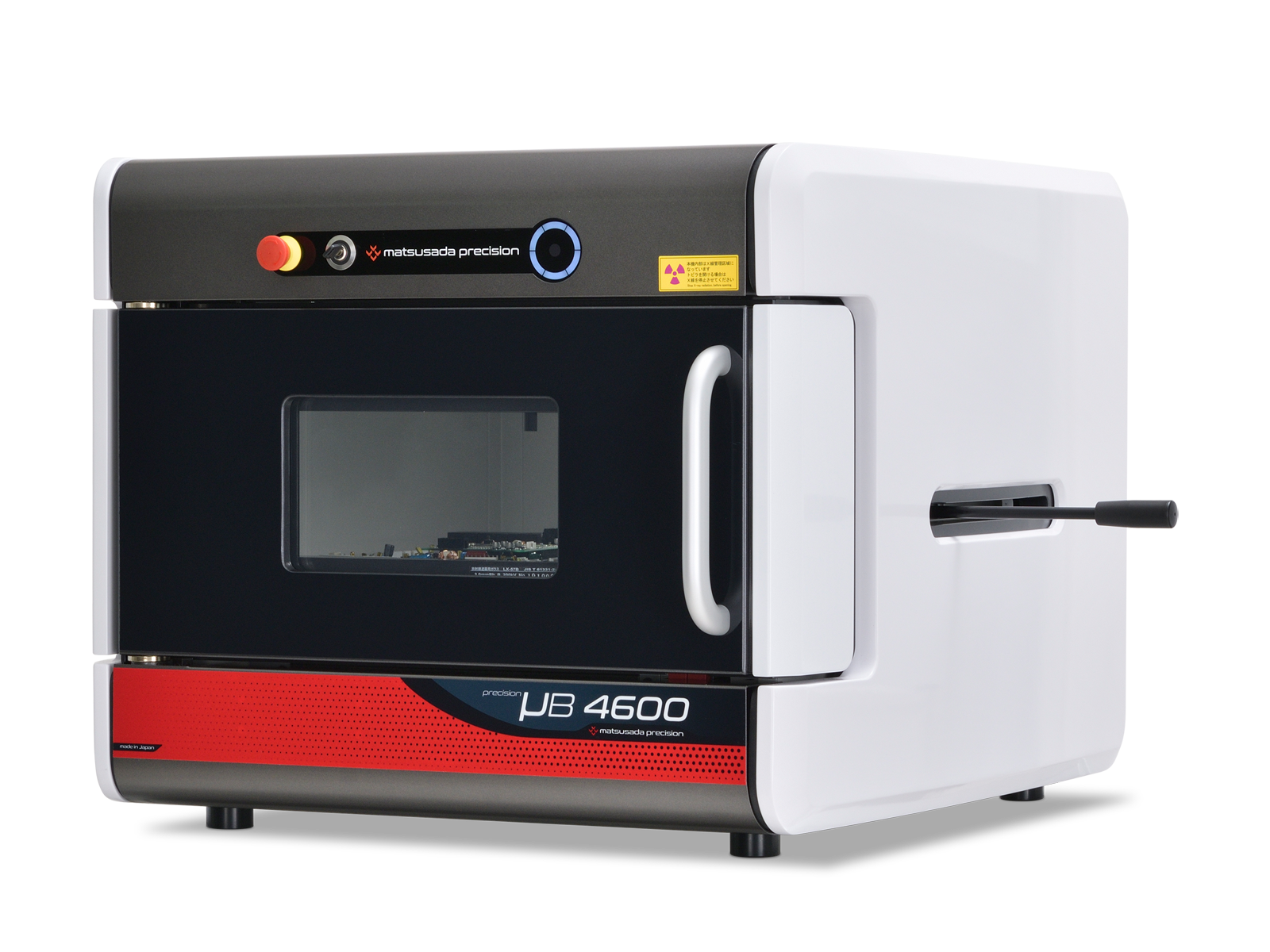

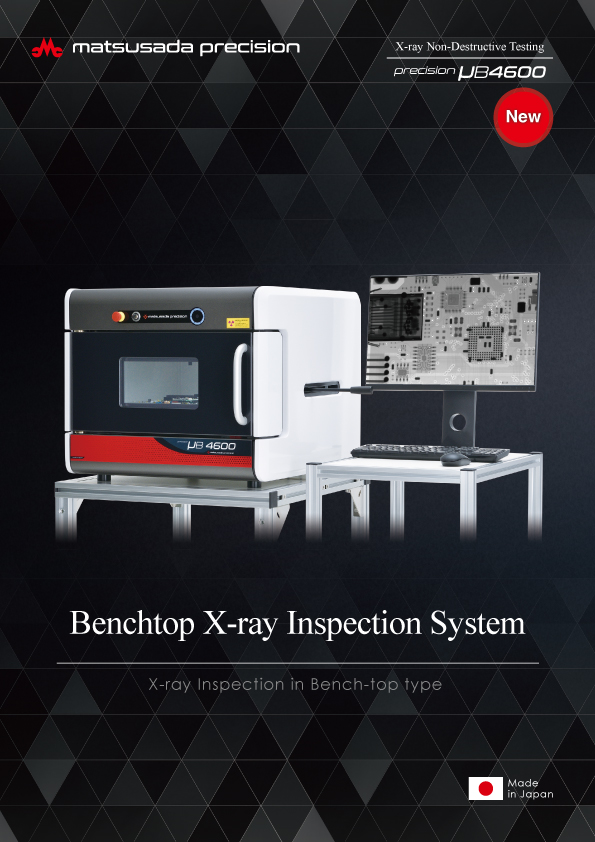

The precision µB4600 is a versatile benchtop X-ray inspection system. The X-ray source can be selected from 60kV, 90kV, and 100kV, and the size of the camera can be selected. Therefore, the X-ray inspection system can be optimized to match the user's inspection target.

Benchtop Radiography System with The High Power X-ray Tube

X-ray tube voltage: 90 kV

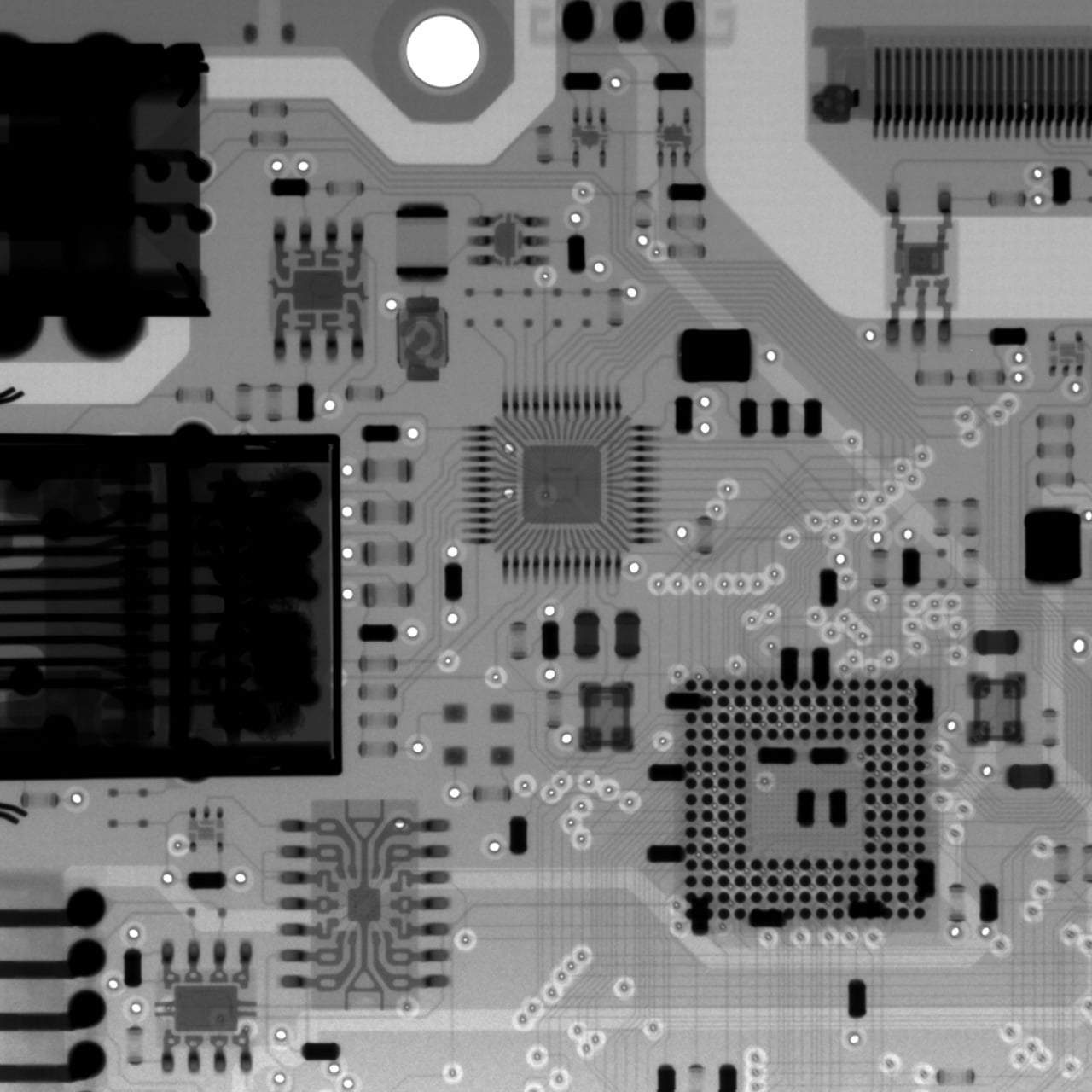

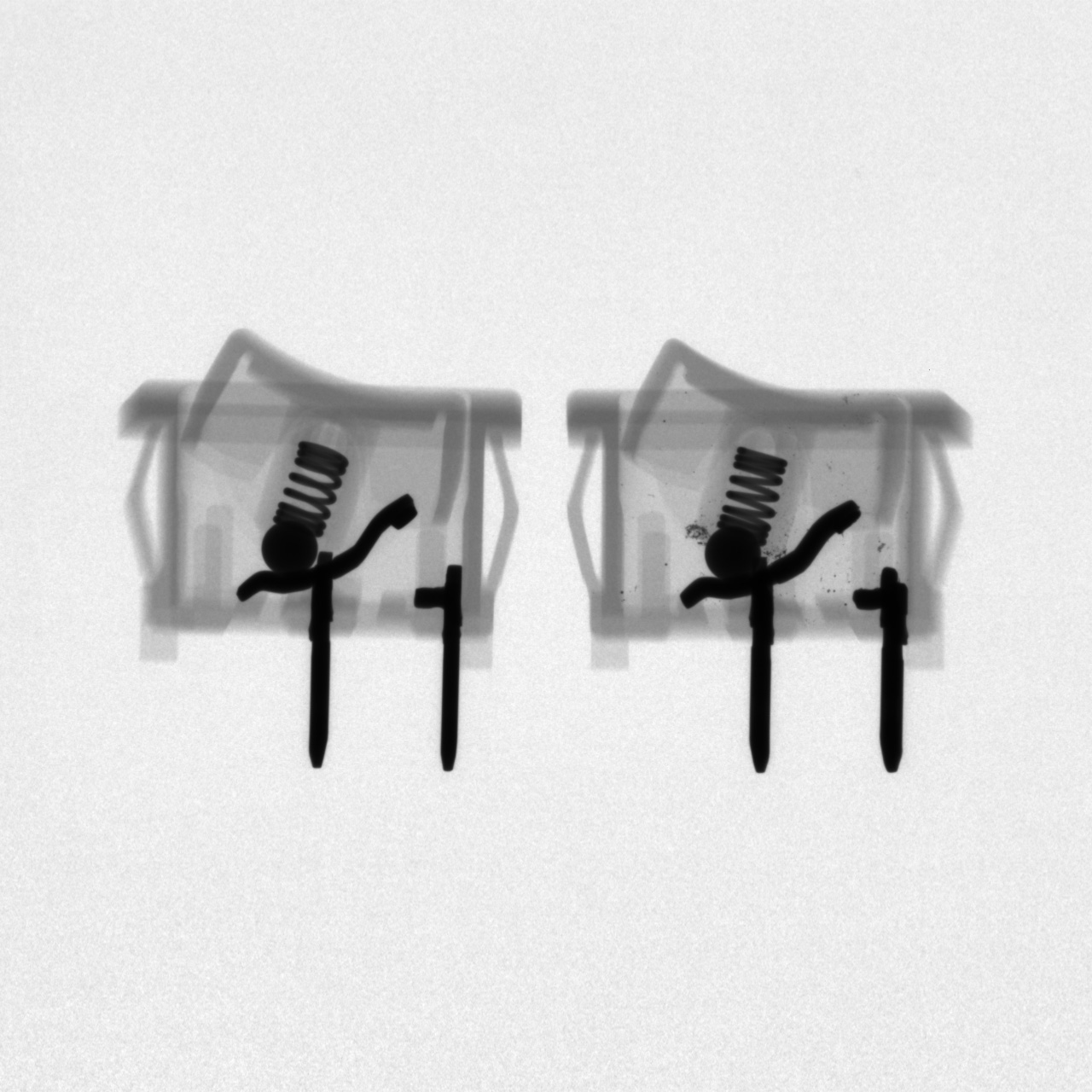

With high transmission X-ray, the new inspection system offers high quality and higher power observations than other benchtop-type products. It enables you to easily observe defects in aluminum die casting, assemblies in metal cases, and welding defects of metal interiors. In addition, using Matsusada Precision high voltage power supplies featuring high stability and long life, the product enables reliable X-ray radiation that creates stable and best X-ray images at high power.

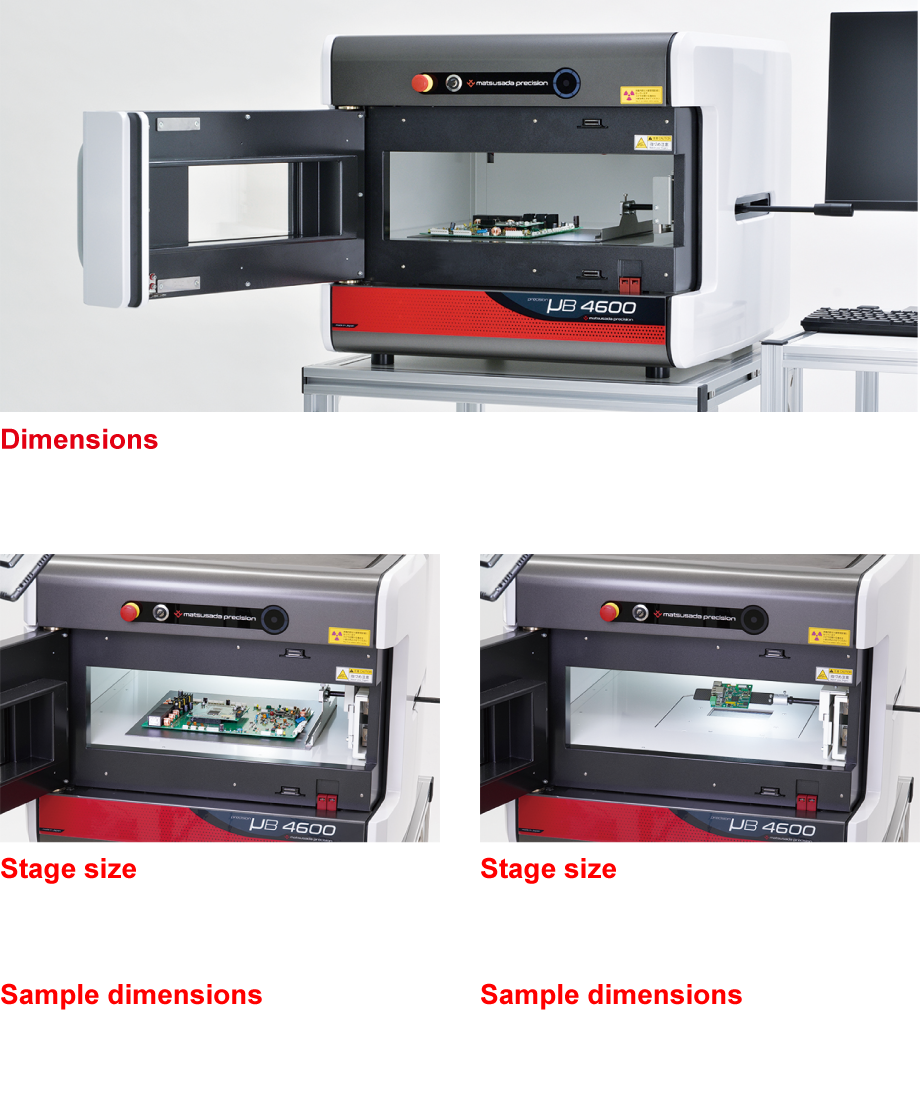

Compact Body with Large Sample Area and Wide Door

Easy operation

With the system dimensions of just 26.97 inches (685 mm) wide, 29.53 inches (750 mm) deep, and 22.24 inches (565 mm) high, it is efficient enough with its large stage of X-axis 13 inches (330 mm) × Y-axis 13.93 inches (340 mm). The system is suitable for large samples equipped with small objects like M-size electronic circuit boards and connectors of cables.

Easy Operation by Manual Stage Handle

Easy operation

With the stage handle and large front viewport for easy operation, you can flexibly move the object to the desired position. Also, alignment is easy since the transmitted X-ray image can be observed in real time during radiation. With the optimized dedicated software having a simple operation panel, even those new to X-ray systems can quickly start the inspection.

Selectable X-ray Tubes and Cameras

With selectable X-ray tubes and cameras, you can configure the system to meet the specific demands of your application.

• Combination Example

- Checking cable disconnection : Mini-focus (60 kV) and 1.5 MP camera: precision µB4600-LEP60

- Checking connector crimping : Microfocus (90 kV) and 1.5 MP camera: precision µB4600-LEM90

- Observation of 0.1 mm voids in resin moldings : Microfocus (60 kV) and 3 MP camera: precision µB4600-LEF3M60

| Model | X-ray tube | X-ray tube voltage | X-ray tube current | Camera |

Maximum inspection area |

|

|---|---|---|---|---|---|---|

| Standard | precision µB4600 | Mini-focus 100 µm | 90 kV | 0.5 mA |

1.5 mega pixels (Standard) |

X: 2.28 inches (58 mm) x Y: 2.01 inches (51 mm) |

| Optional Model in X-ray tube |

precision µB4600-LP60 | Mini-focus 50 µm | 60 kV | 1 mA | ||

| precision µB4600-LM60 | Microfocus 5 µm | 60 kV | 150 µA | |||

| precision µB4600-LM90 | Microfocus 5 µm | 90 kV | 150 µA | |||

|

Optional model in X-ray tube and camera |

precision µB4600-LF3P60 | Mini-focus 50 µm | 60 kV | 1 mA |

3 mega pixels (Optional) |

X: 3.7 inches (94 mm) x Y: 2.09 inches (53 mm) |

| precision µB4600-LF3M60 | Microfocus 5 µm | 60 kV | 150 µA | |||

| precision µB4600-LF3M90 | Microfocus 5 µm | 90 kV | 150 µA | |||

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

Login Required

-

precision µB4600

Date: 2025-08-07 rev 06

PDF (4,458 KB) -

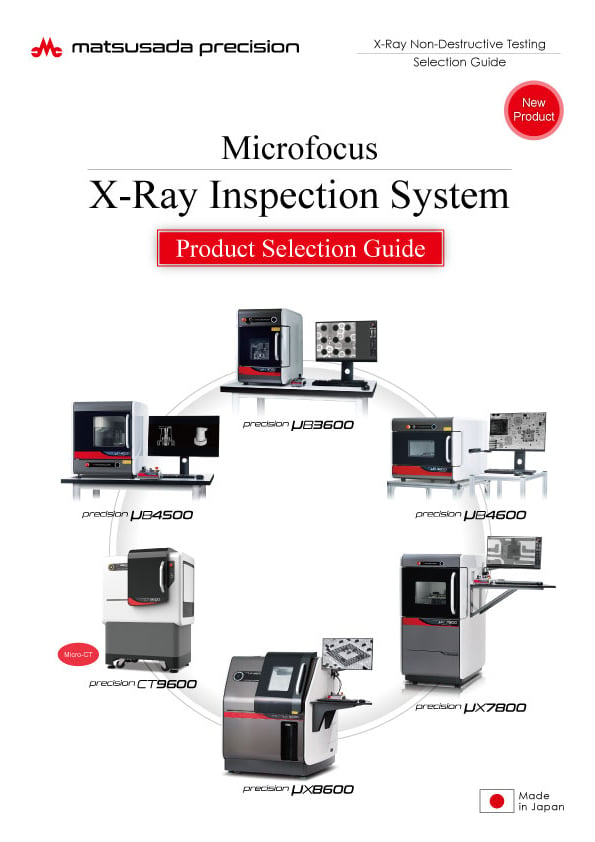

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-05-07 rev.06

PDF (13,911 KB)

Related Technical Articles

Similar products

-

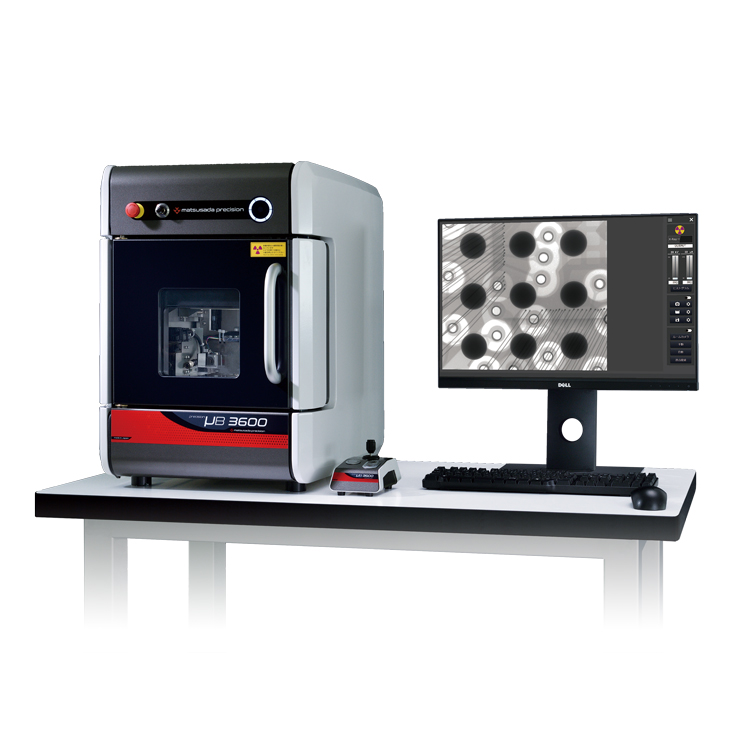

precision µB3600

- X-ray Tube Voltage

- 90 kV

- X-ray Power

- 13.5 W

X-ray Inspection SystemBenchtop High-spec Model

-

New

precision µB3200

- X-ray Tube Voltage

- 60 kV

- X-ray Power

- 9 W

X-ray Inspection SystemBenchtop Entry Model

-

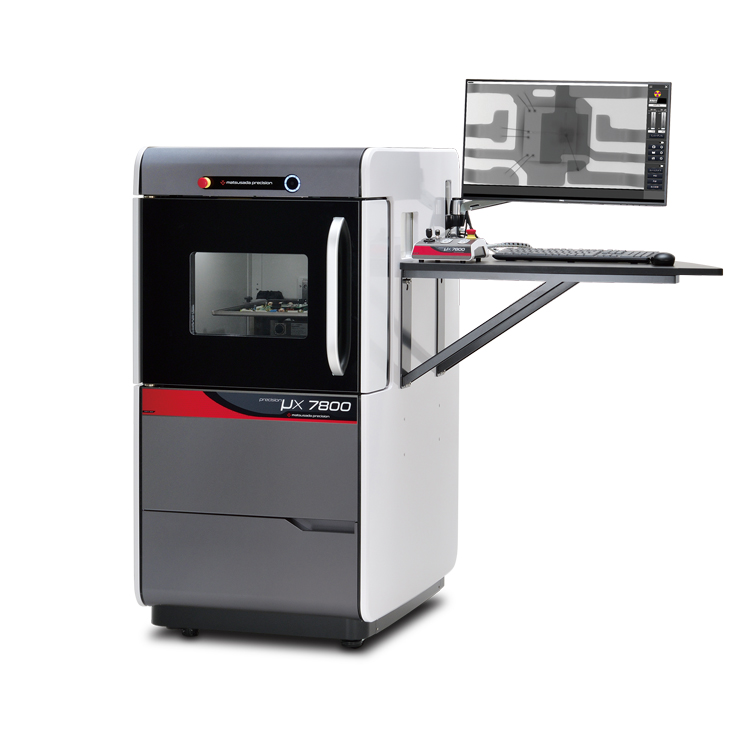

precision μX7800

- X-ray tube voltage

- 90 kV

- X-ray power

- 18 W

X-ray Inspection SystemAll-round Model

Product Lineup:

X-ray Inspection SystemsUser Support

FAQ

- What is Micro‑focus X‑ray?

- What is the tube voltage for X‑ray inspection systems?

- What is the difference between medical and industrial X‑ray systems?

- What is the difference between sintering and die‑attach in power semiconductors?

- Is a license required for usage of X‑ray inspection system?

- May I see the demonstration of the X‑ray inspection system?