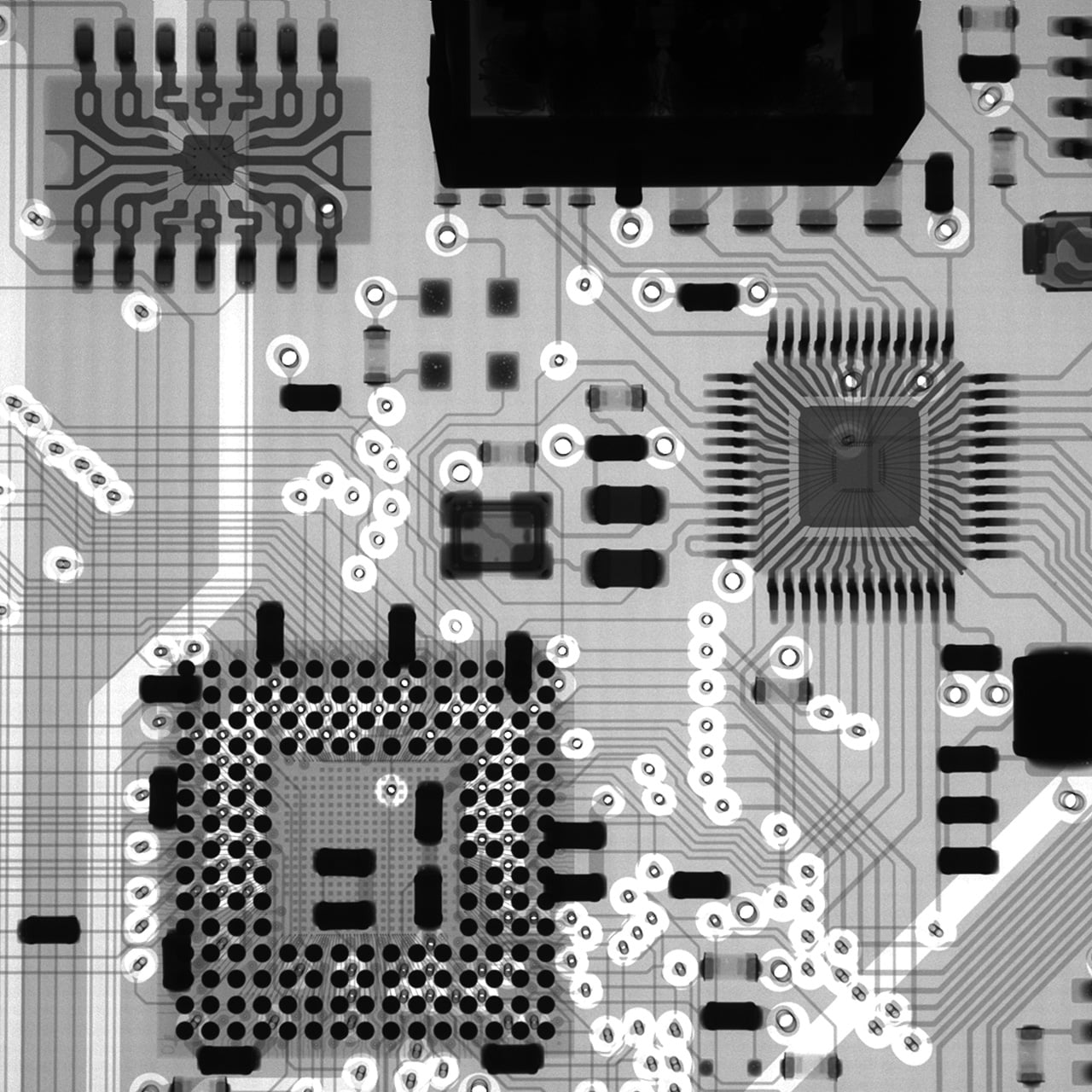

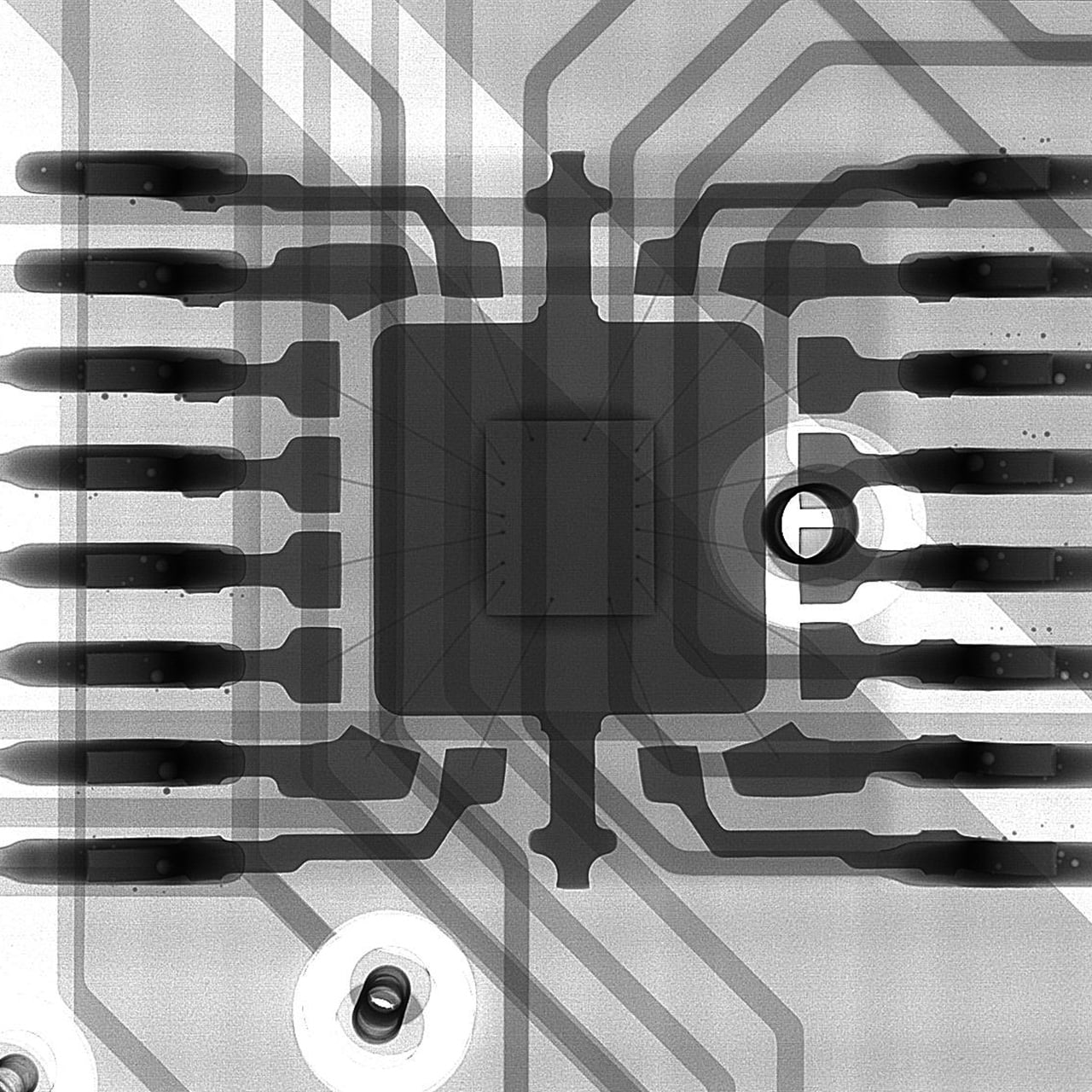

The precision µB3200 is a compact, cost-effective 60 kV benchtop X-ray inspection system designed for spot-checking SMT lines. It delivers reliable defect detection for printed circuit boards (PCBs), supporting quality assurance processes in the global SMT industry.

Optimized for Small Components

The precision µB3200 is a compact, entry-level X-ray inspection system. Its space-saving design allows for easy installation on a workbench in laboratories, offices, or production facilities with limited space. The geometric magnification can be easily adjusted by changing the detector height.

Stage Dimensions and Inspection Area

The precision µB3200 is engineered for imaging small circuit boards and electronic components. It offers a maximum monitor magnification of 125x. The effective field of view (FOV) is 2.5 mm × 2.8 mm, with a stage travel range of 150 mm × 200 mm, covering a wide variety of sample sizes.

Simplified Maintenance

X-ray Tube Unit Replacement

The system is designed for easy maintenance. The X-ray tube unit can be accessed by removing the top and rear panels and is easily removed from the bottom section for replacement.

X-ray Detector Replacement

The detector unit, mounted securely inside the top of the chamber, uses a slide-out mechanism for quick and simple replacement.

Safety Features

Prior to delivery, every unit undergoes rigorous testing to ensure X-ray leakage is less than 1 µSv/h at any point on the surface. This extremely low level ensures a safe working environment for operators.

-

Door Interlock System

The X-ray output is automatically disabled when the door is open. If the door is opened during operation, the safety interlock immediately cuts off X-ray emission to protect the operator.

-

Product status display LED

It indicates the product status on the front panel if the X-ray irradiation is on, the door is open, and other status.

-

Auto-off Timer

To prevent accidental continuous irradiation, the system features an auto-off timer. Users can preset a duration after which the X-ray source will automatically turn off, ensuring energy efficiency and safety.

-

Emergency stop button

When you press the emergency stop button, the X-ray is stopped immediately.

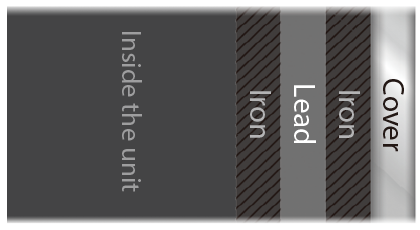

Advanced Shielding Technology

For durable and reliable safety, the cabinet employs a multi-layered shielding structure combining lead and steel plates. This design prevents the deformation often associated with soft lead materials, ensuring long-term shielding integrity.

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

Related Technical Articles

Similar products

-

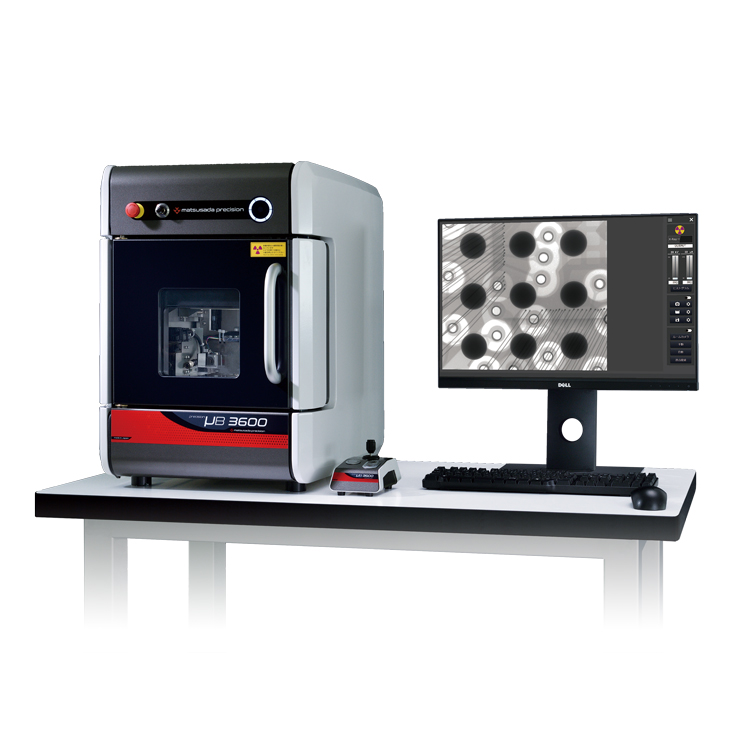

precision µB3600

- X-ray Tube Voltage

- 90 kV

- X-ray Power

- 13.5 W

X-ray Inspection SystemBenchtop High-spec Model

-

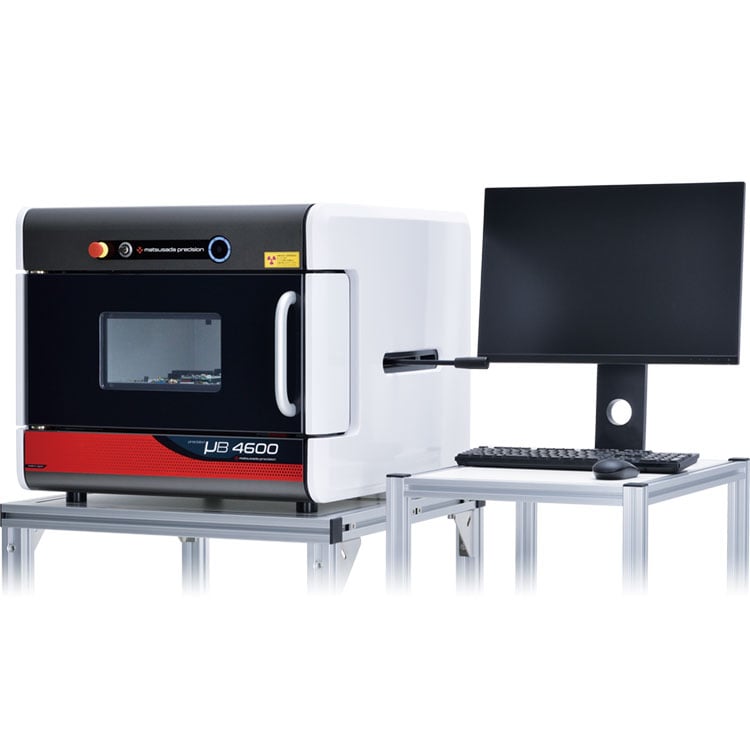

New

precision µB4600

- X-ray Tube Voltage

- 60 to 90 kV

- X-ray Power

- 9 to 60 W

X-ray Inspection SystemHigh Power Model

-

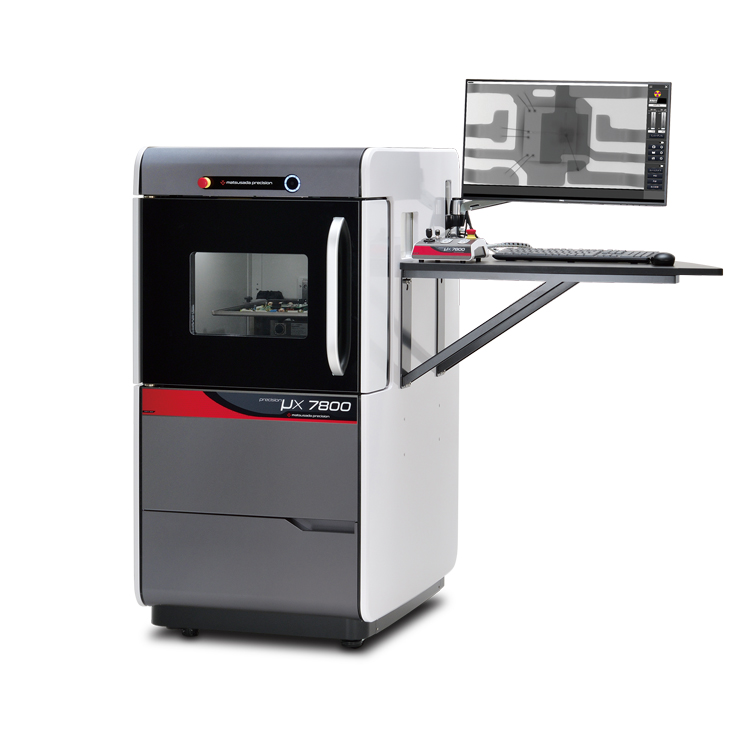

precision μX7800

- X-ray tube voltage

- 90 kV

- X-ray power

- 18 W

X-ray Inspection SystemVersatile General-Purpose Model

Product Lineup:

X-ray Inspection SystemsUser Support

FAQ

- What is Micro‑focus X‑ray?

- What is the tube voltage for X‑ray inspection systems?

- What is the difference between medical and industrial X‑ray systems?

- What is the difference between sintering and die‑attach in power semiconductors?

- Is a license required for usage of X‑ray inspection system?

- Which X-ray inspection systems are suitable for our application?