Thermocouples measure temperature using the Seebeck effect, which generates an electromotive force (EMF) at the junction of two dissimilar metals. While widely used in industrial applications, ensuring the reliability of these sensors requires verifying the condition of the metal junction.

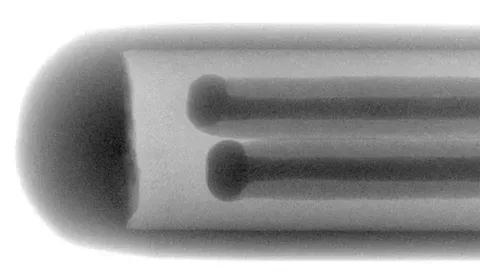

For exposed sensors, the wire connections can be inspected visually. However, sheathed thermocouples enclose the junction within a protective tube, making visual assessment impossible. X-ray inspection systems are essential for verifying the internal structure and junction integrity of these sensors without damaging them.

Matsusada Precision offers X-ray inspection systems capable of visualizing the internal wiring and contact positions of sheathed thermocouples with high resolution. We also offer specialized configurations designed to accommodate long protective tubes, allowing for easy inspection of extended thermocouple assemblies.

Customized X-ray Inspection System for Thermocouples (Example)

The system features side-access ports, allowing long thermocouples to pass through the unit for inspection.

Related Terms:

Thermocouple, Sheathed thermocouple, Nondestructive testing, Seebeck effect, Temperature sensor

Recommended products

Related Technical Articles

- Selecting an X-ray Inspection System

- Principles of Radiography

- Safe Operation of X-ray Inspection Systems

- What is Microfocus X-ray Technology? (Basic Knowledge)

- Basics and Principles of Computed Tomography (CT)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety