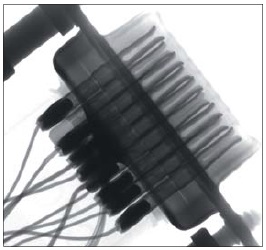

X-ray inspection is essential for identifying defects in connectors, harnesses, crimped parts, and soldered joints. It enables non-destructive detection of internal wire breakage, shorts, missing crimps, and solder voids. For connectors with multiple pins, overlapping metal parts can obscure defects. To address this, the system allows for oblique observation by rotating the sample stage, ensuring a clear view from multiple angles.

The μRay8700 X-ray inspection system features a high-power 130 kV, 40 W microfocus X-ray source, delivering clear images even through dense overlapping metal components. Additionally, the optional CT scan function enables cross-sectional analysis, providing a detailed view of internal cable strands within crimping areas and identifying solder voids.

| Focal Spot | Microfocus |

|---|---|

| X-ray Tube Voltage | 90 to 130 kV |

| Magnification | 1 to 100x |

Recommended products

Related Technical Articles

- Selecting an X-ray Inspection System

- Principles of Radiography

- Safe Operation of X-ray Inspection Systems

- What is Microfocus X-ray Technology? (Basic Knowledge)

- Basics and Principles of Computed Tomography (CT)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety