Nondestructive Testing is an inspection technique that enables us to check the internal conditions of mechanical parts and structures without destroying the object. X-rays and ultrasonic waves are injected into the object, and the resulting images and echoes are used to check for internal flaws and deterioration.

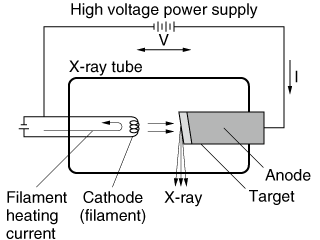

In Nondestructive inspection systems that use X-rays, an X-ray tube is used as the device that generates the X-rays. In X-ray nondestructive inspection, X-rays generated from the X-ray tube are irradiated onto the object to be inspected, and a transmitted image is captured by an X-ray detector such as a FPD. From the images taken, defects, corrosion, deterioration, etc., are inspected.

In ultrasonic inspection, an ultrasonic generator is used. In the ultrasonic generator, a high-frequency voltage is applied to a piezoelectric element that expands and contracts depending on the voltage, and the vibrations are used to generate ultrasonic waves. In ultrasonic testing, ultrasonic waves are applied to the object to be inspected, and the reflected waves are measured for internal inspection.

Matsusada Precision offers a wide range of equipment for nondestructive testing, including not only X-ray nondestructive testing equipment but also high-voltage power supplies for X-ray tubes and high-frequency power supplies for driving piezoelectric elements.

- Related words:

-

- Radiographic Testing (RT)

- Ultrasonic testing (UT)

- Eddy-current

- Magnetic-particle

- X-ray

Recommended products

Matsusada Precision offers a wide range of nondestructive testing equipment, including X-ray nondestructive testing equipment, high-voltage power supplies for X-ray tubes, and high-frequency power supplies for driving piezoelectric elements.

Information on related articles in Technical Knowledge

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- The Right Way to Choose appropriate X-ray Inspection System

- Principles of Radiography

- How to use X-ray Inspection System safely

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Radiation Effects on the Human body and the safety of X-ray equipment

- What is Microfocus X-ray? (Basic Knowledge)

- Computed Tomography (CT) Basic and Principle

- How to Take Beautiful X-ray CT Images? - X-ray Non-Destructive Inspection series (1) -

- How to View X-ray CT Images - X-ray Non-Destructive Inspection series (2) -

- X-ray Image Processing and Automated Inspection - X-ray Non-Destructive Inspection series (3) -

- Types of X-ray tubes and high-voltage power supplies

- What is X-Ray Fluorescence? (Basic Knowledge)