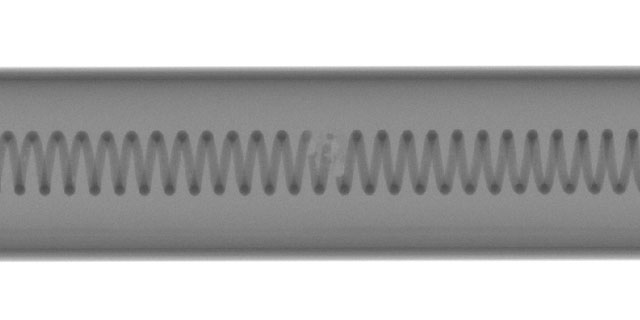

Industrial heaters include sheathed heaters, panel heaters, ribbon heaters, hot plates, and cartridge heaters. The heater generates heat due to its resistance when the resistance wire (resistance heating wire) is energized. Sheath heaters cover resistance wires with a metal tube to prevent electric shock and make them easier to handle. In X-ray inspection of industrial heaters, internal inspections for Galvanic isolation defects, wire breaks, and short circuits are available.

Matsusada Precision produces X-ray inspection systems that can nondestructively inspect various heaters, such as sheathed and ceramic heaters. Using Computed Tomography and 3D X-ray scan, it is possible to inspect the heater's interior that cannot be visually inspected.

We also have dedicated X-ray inspection systems that can accommodate long heaters.

Related words:

Industrial heaters, Seed heaters, Cartridge heaters, Ceramic heaters, Resistance wire, Resistance heating wire

Recommended products

Related Technical Articles

- Types of Resistors: A Guide to Basic Electronic Components

- Selecting an X-ray Inspection System

- Principles of Radiography

- Basics and Principles of Computed Tomography (CT)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety