The Importance of Internal Inspection

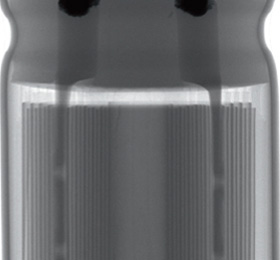

Quality control is critical for aluminum electrolytic capacitors, as internal defects like film miswinding can lead to failures or even fires. Since visual inspection is impossible once the capacitor is sealed in its casing, X-ray inspection systems are essential for nondestructive internal analysis.

Requirements for High-Precision Imaging

Detecting subtle defects--such as loose windings or foreign objects inside the capacitor--requires an X-ray inspection system equipped with a microfocus X-ray tube and a high dynamic range camera. High contrast and high resolution are necessary to clearly visualize the internal film structure and ensure product reliability.

Matsusada Precision Solutions

Matsusada Precision's X-ray inspection systems deliver low-noise, high-contrast images by combining stable microfocus X-ray tubes--engineered using our core high-voltage technology--with high-resolution Flat Panel Detectors (FPDs).

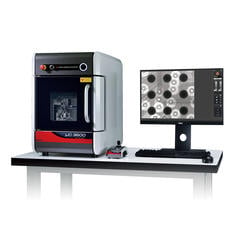

Recommended Model: precision μB4500

The precision μB4500 is a benchtop X-ray inspection system featuring a horizontal irradiation method ideal for capacitor inspection. Equipped with a 5 µm focal spot X-ray tube and a 3-megapixel FPD, it captures clear, detailed images, ensuring reliable detection of defects without overlooking minute irregularities.

| Focal Spot | Microfocus |

|---|---|

| X-ray Tube Voltage | 90 kV |

| Magnification | 1 to 100x |

Recommended products

Related Technical Articles

- Types of Capacitors: A Basic Guide to Electronic Components

- Selecting an X-ray Inspection System

- Principles of Radiography

- Safe Operation of X-ray Inspection Systems

- What is Microfocus X-ray Technology? (Basic Knowledge)

- Basics and Principles of Computed Tomography (CT)

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety