X-ray inspection is essential for non-destructive analysis of cable interiors. Standard electrical continuity tests may fail to detect broken wires if the severed ends remain in contact due to the cable's position or bending. However, these connections are unstable and prone to failure when the cable moves. X-ray imaging allows operators to visually verify the physical integrity of internal wires, detecting breaks even when intermittent electrical contact exists.

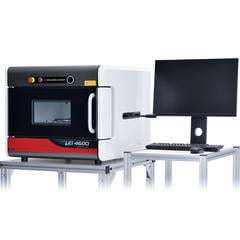

High-power X-ray systems are ideal for inspecting cables with thick insulation, complex wire bundles, or metal shielding. The benchtop X-ray system precision µB4600 is equipped with a high-output 100 kV X-ray tube, enabling clear, high-contrast imaging of diverse multicore cables that lower-power systems cannot effectively penetrate.

| Focal Spot | Less than 100µm (mini-focus) |

|---|---|

| X-ray Tube Voltage | 90 kV |

| Magnification | 1 to 10x |

Recommended products

Related Technical Articles

- Selecting an X-ray Inspection System

- Principles of Radiography

- Safe Operation of X-ray Inspection Systems

- Basics and Principles of Computed Tomography (CT)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety