Industrial CT

X-ray CT scanners are primarily classified into two main categories: medical and industrial.

- Medical CT scanners

- For medical CT scanners, the utmost priority is to minimize the patient's exposure to radiation during the examination.

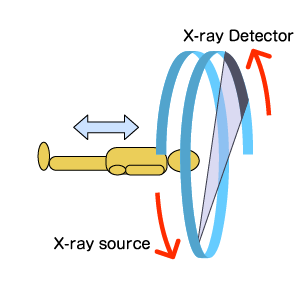

- To create a 3D image, the X-ray tube aand detector rotate around the patient. This process requires a high X-ray output (high dose rate) for a very short exposure time to minimize motion artifacts and complete the scan quickly.

- Industrial CT scanners

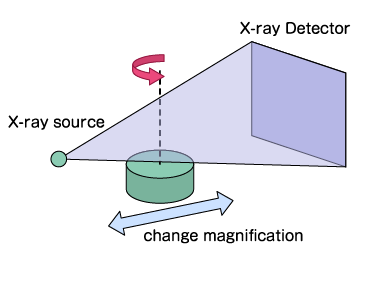

- In contrast, radiation exposure to the object is not a concern for industrial products. Therefore, the X-ray tube and detector can remain stationary while the object is rotated on a turntable. This allows for longer exposure times using a lower dose rate. As a result, industrial CT scanners can produce high-resolution, low-noise data with exceptional accuracy. This makes them ideal for a wide range of applications, including quality inspection, material evaluation, and reverse engineering.

High voltage power supplies for X-ray tubes used in industrial CT inspection systems, as well as integrated X-ray tube and high-voltage power-supply units, have long been part of Matsusada Precision's product lineup. However, sales of the integrated models have now been discontinued.

Recommended products

Related Technical Articles

- Basics and Principles of Computed Tomography (CT)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety

- What is Microfocus X-ray Technology? (Basic Knowledge)

- What is X-Ray Fluorescence? (Basic Knowledge)