The µRay8700/µRay8760 is a versatile micro-CT system designed to inspect a wide range of objects, from small components to large assemblies. Equipped with a high-power 130 kV, 40 W microfocus X-ray source, the system delivers high-definition 2D images with low noise and 3D reconstructions with exceptional spatial resolution.

The μRay8700 and μRay8760 are versatile, high-power micro-CT systems designed to accommodate a wide spectrum of sample sizes, from small components to larger objects.

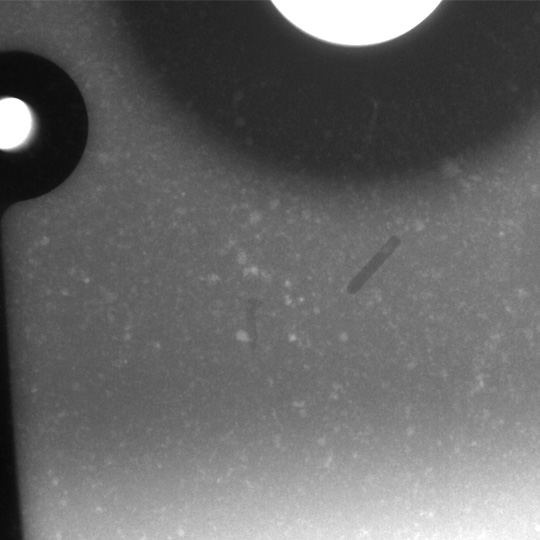

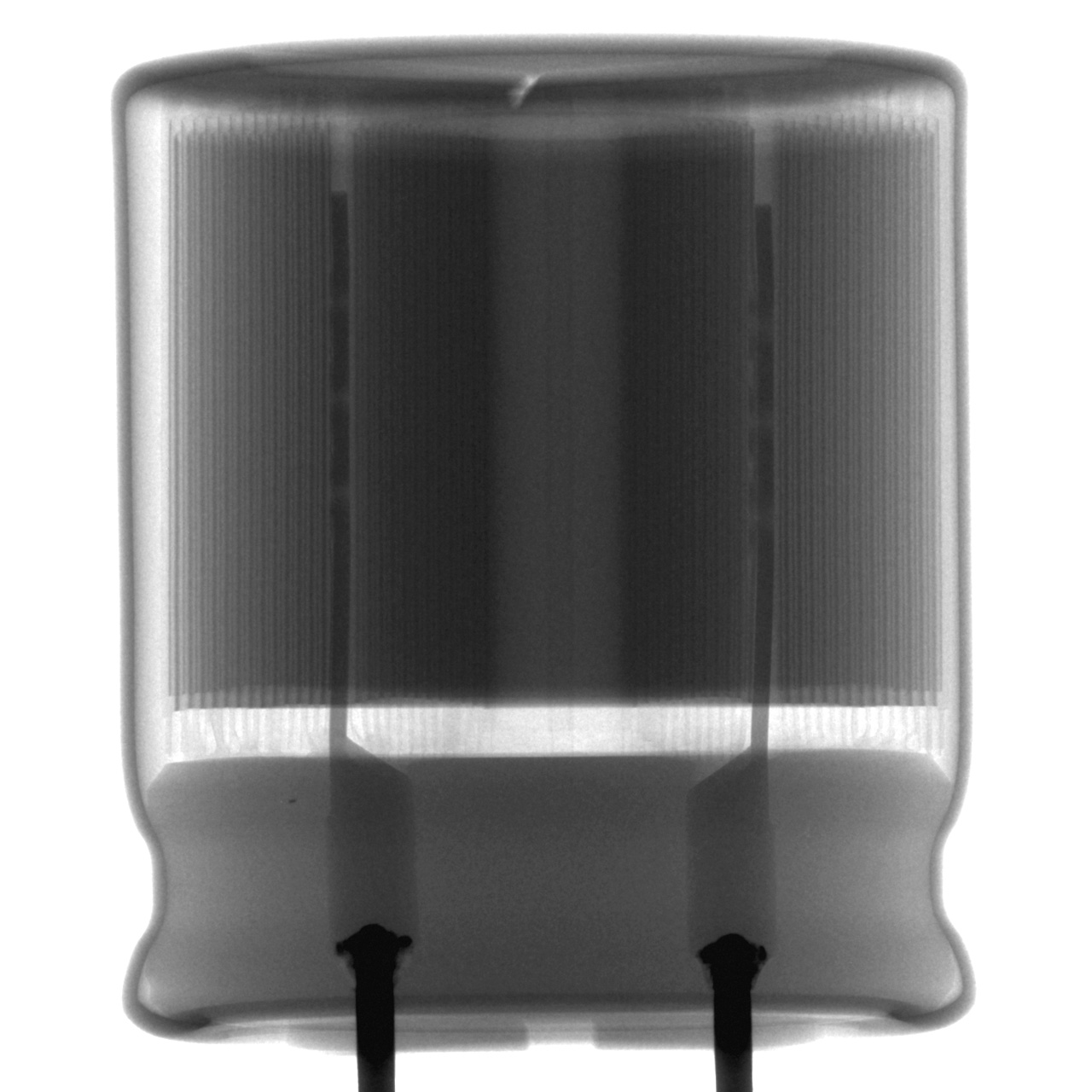

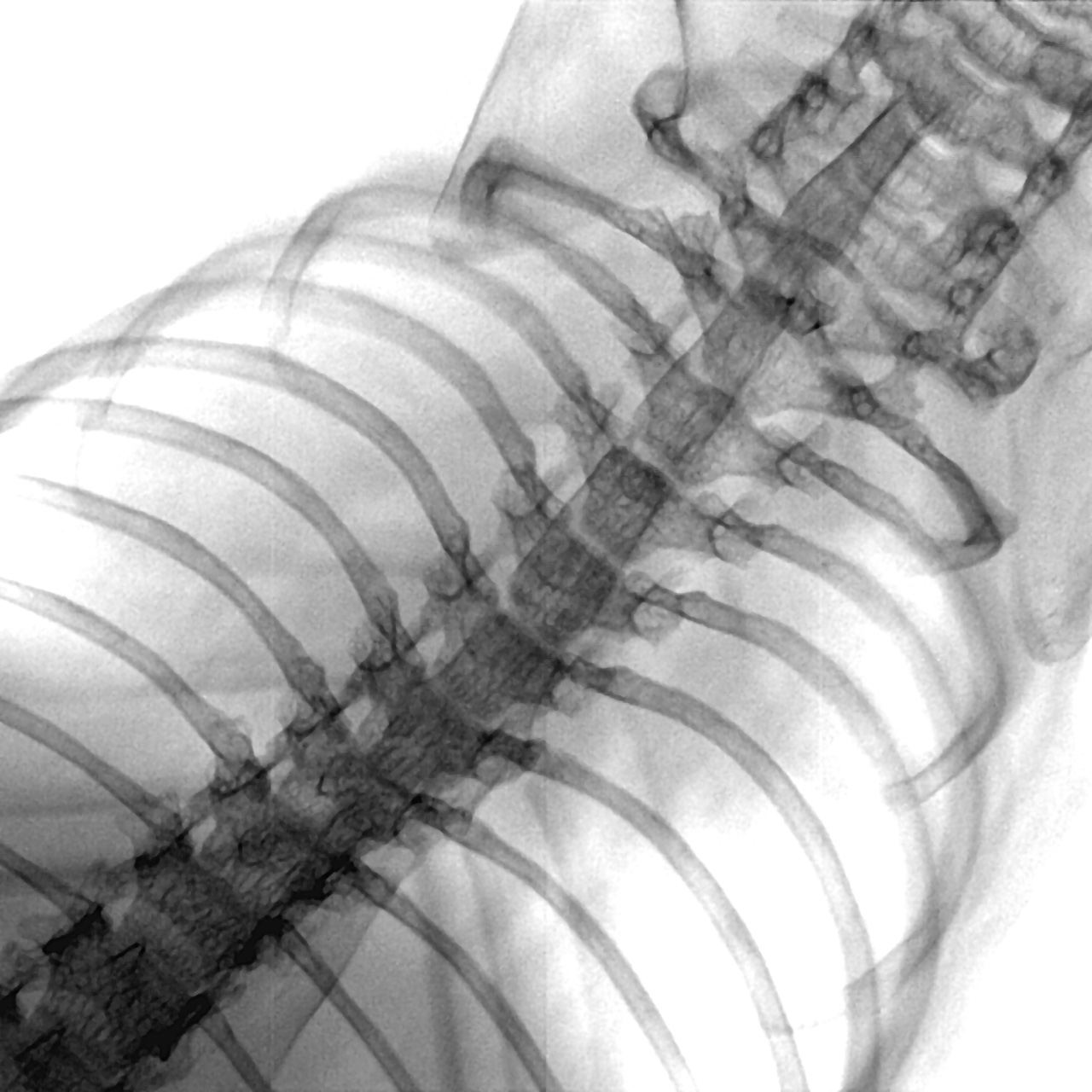

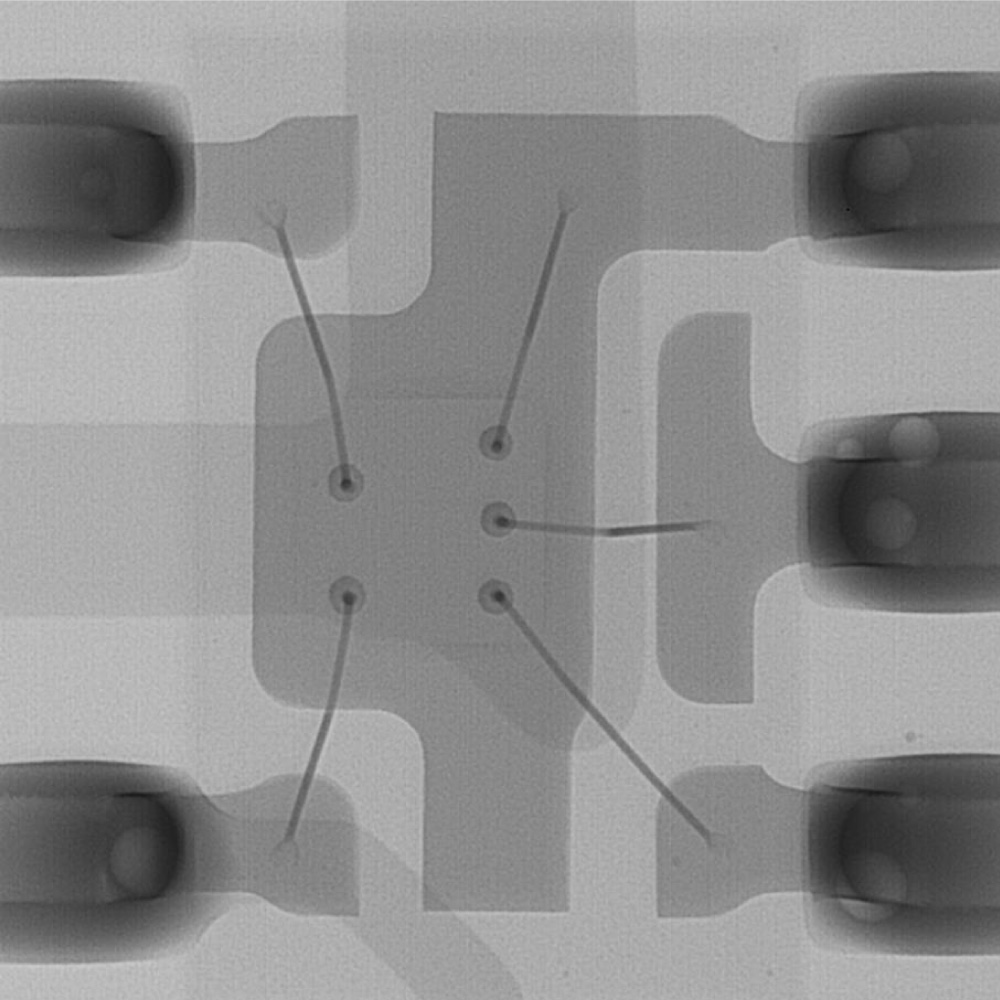

At the heart of these systems is a powerful 130kV, 40W microfocus X-ray source. This high-power output ensures excellent penetration capabilities, even for dense materials, resulting in low-noise, high-definition 2D transmission images. For 3D analysis, this translates to CT reconstructions with exceptional spatial resolution and clarity. These systems are perfectly suited for the non-destructive inspection of aluminum die-cast parts, resin moldings, and other industrial components where both internal integrity and dimensional accuracy are critical.

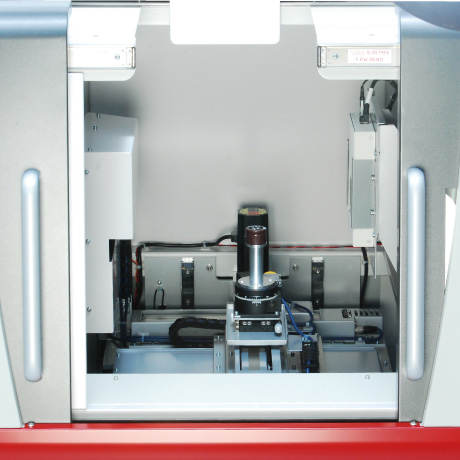

Horizontal X-ray Beam for Easy Cross-Sectional Inspection

The system features a horizontal X-ray beam configuration, ideal for inspecting longitudinal cross-sections. In addition to X, Y, and Z-axis control, the stage includes a rotation axis, enabling 360-degree observation of the entire object. Cylindrical samples or complex workpieces can be placed on the stage and rotated to identify internal defects easily.

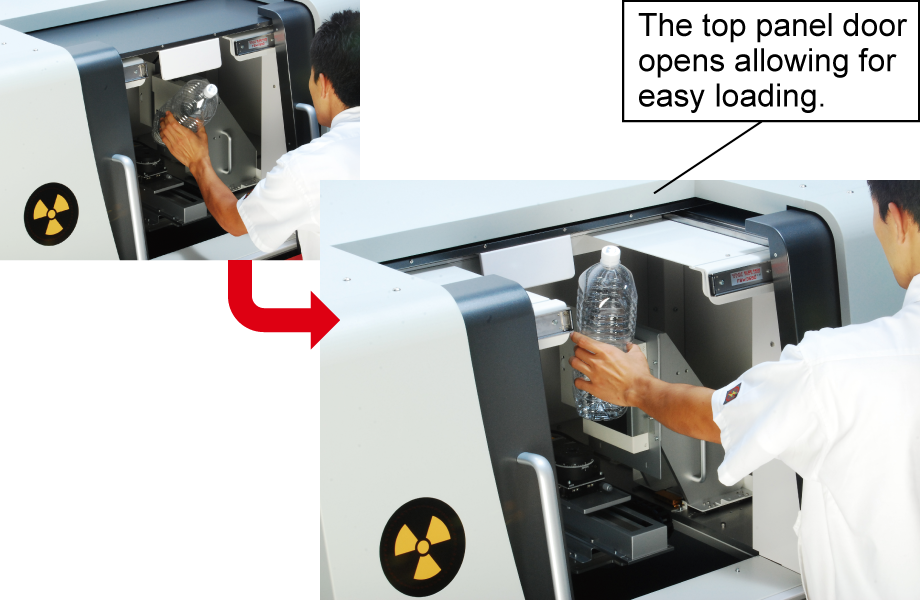

Top Access for Accommodating Long and Heavy Samples

The top panel opens to facilitate the loading of long samples or heavy workpieces up to 10 kg.

* Top panel access is available on the µRay8700 model only.

* Support for 10 kg samples is an optional configuration.

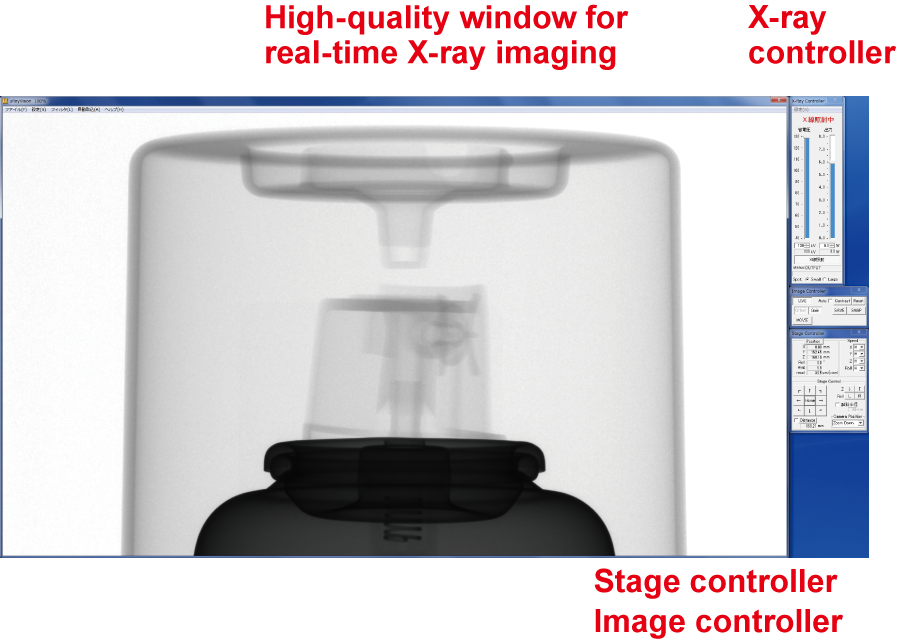

Software [µRay®Vision]

Intuitive operation allows operators of any skill level to access advanced functions immediately.

The dedicated µRay®Vision software simplifies stage control and X-ray operation while providing a comprehensive suite of image processing and measurement tools.

Simple Observation and Analysis

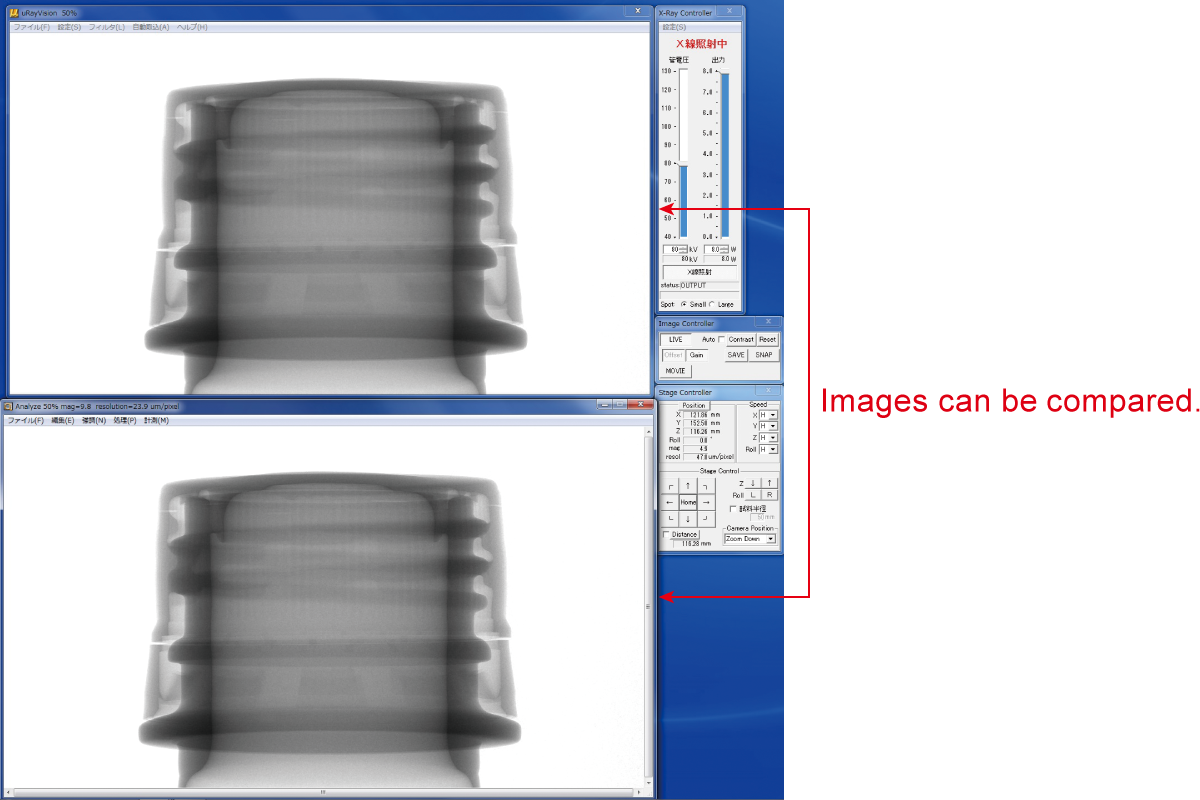

Flexible display modes allow for easy comparative observations.

By switching between high-resolution and overview display modes, users can analyze samples by comparing live feeds with previously saved images.

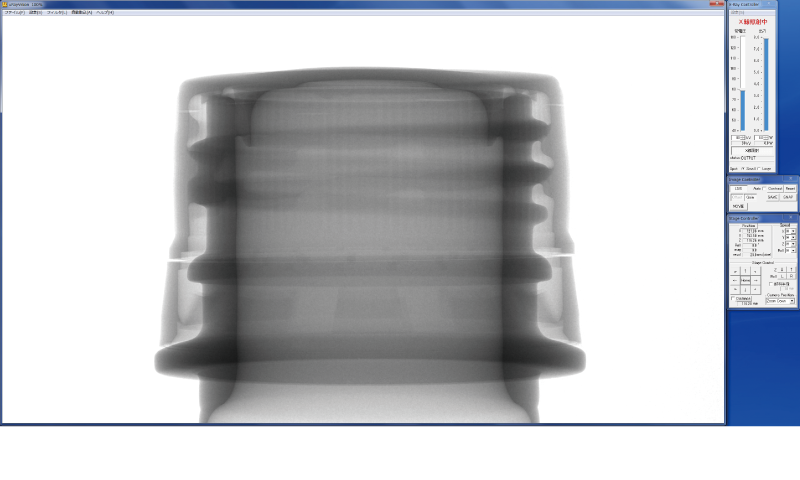

Easy operation for image processing and analysis

With the exclusive software as standard, advanced image processing and analysis are available in simple operations

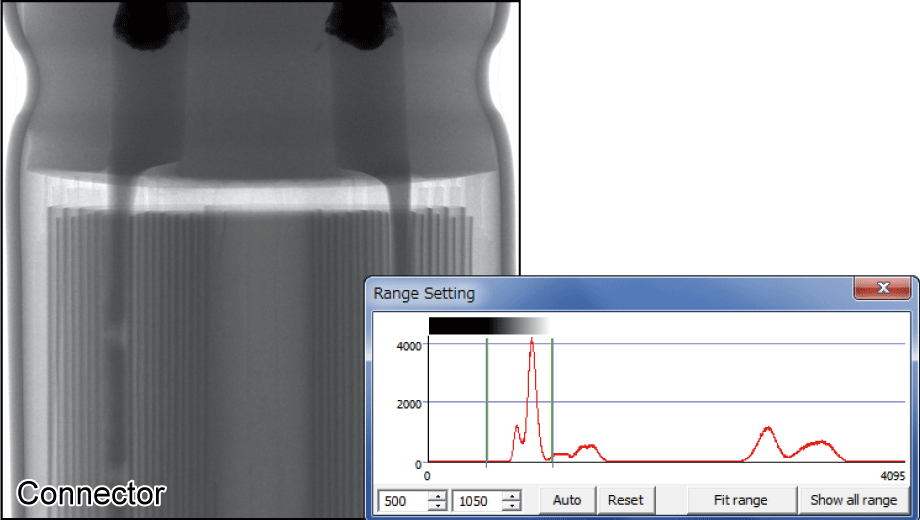

Display Range

Allows users to set specific gray levels based on the image histogram to manually enhance contrast.

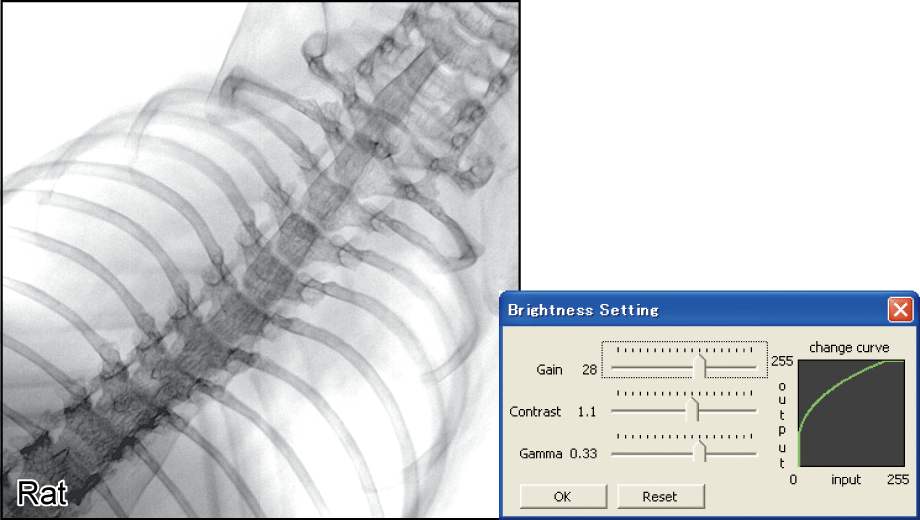

Brightness control

Individually controlling the gain, contrast, and gamma values allows for a flexible change of the brightness value of images.

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

Login Required

-

µRay8700/µRay8760 Datasheet

Date: 2024-01-09 Rev.06

PDF (3,836 KB) -

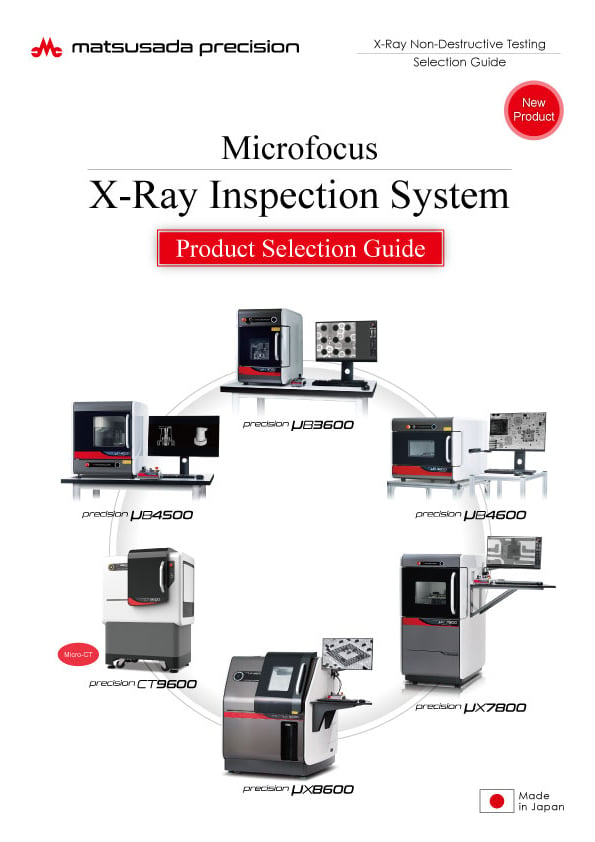

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-05-07 rev.06

PDF (13,911 KB) -

Micro View X-Ray CT System Guide

Date: 2025-09-12 Rev 08

PDF (4,989 KB)

Related Technical Articles

Similar products

-

New

precision CT9600

- X-ray tube voltage

- 130 kV

- X-ray power

- 40 W

X-ray Micro-CT Scanner -

New

precision μX8600

- X-ray tube voltage

- 130 kV

- X-ray power

- 40 W

Microfocus X-Ray Inspection SystemTop and Oblique Angle View

-

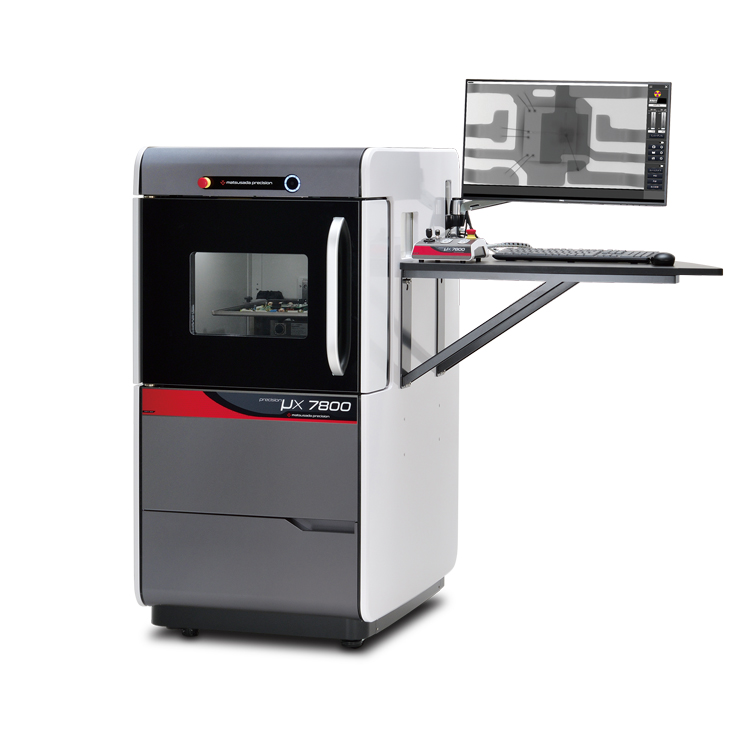

precision μX7800

- X-ray tube voltage

- 90 kV

- X-ray power

- 18 W

X-ray Inspection SystemAll-round Model

-

μRay8400

- X-ray tube voltage

- 130 kV

- X-ray power

- 40 W

130 kV micro focus X-raySuitable for observing large footprint material or specimens

Product Lineup:

X-ray Inspection SystemsUser Support

FAQ

- What is Micro‑focus X‑ray?

- What is the tube voltage for X‑ray inspection systems?

- Is a license required for usage of X‑ray inspection system?

- What is the difference between medical and industrial CT scans?

- What is the difference between an X‑ray inspection system and a CT scan system?

- How do we reduce concentric circle noise (ring artifact) in CT images?