Front-end and back-end processes

The process of manufacturing semiconductors is similar to that of making business cards.

In the case of business cards, the first step is to finalize a design, followed by printing several copies of the design on a large sheet of paper. Finally, the printed matter is cut to produce individual business cards.

The semiconductor manufacturing process is similar. Semiconductor manufacturing is divided into design, front-end, and back-end processes, with the design process being the design and the front-end process being printing. The next step was to cut the samples into pieces.

Semiconductors undergo a design process, and large-scale integrated circuits (LSI) are created on silicon wafers in the front-end process. The integrated circuit was then cut into individual chips using a back-end process. In this article, we discuss the back-end process.

Outline of back-end process

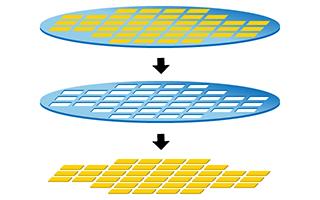

In the back-end process, the semiconductor is cut from the wafer and converted into a product. In the front-end process, large-scale integrated (LSI) circuits with hundreds of semiconductors lined up on a wafer made from silicon ingots are created. In the back-end process, these integrated circuits are cut out individually and processed in various ways so that they can be used as products.

The back-end processing is as follows:

-

Dicing: The wafer is cut with a diamond blade and separated into individual chips. In the dicing process, the wafer was attached to a dicing tape, and a rotating circular diamond blade was used to separate the semiconductors while spraying ultrapure water.

In addition to the diamond blade method, there are other methods of dicing, such as the laser method, which cuts with a laser; the scribe method, which cuts by inserting scratch lines into the wafer to cause cracks; and the plasma dicing method, which uses etching with plasma to separate the wafer.

If dicing tape is used, the tape holding the wafer in place must not be cut. After cutting, the dicing tape was stretched to create a clearance between the chips to facilitate removal and other operations.

-

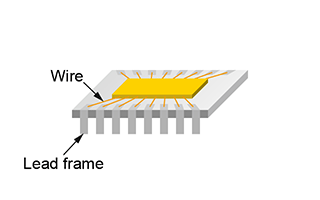

Wire bonding: The chip is fixed to the lead frame (die bonding). A lead frame is a thin metal support for a chip that serves as a terminal for mounting a semiconductor on a board.

Some lead frames can diffuse heat, and in some cases, such as in the manufacture of power semiconductors, they are mounted on heat sinks instead of lead frames. In die bonding, adhesives such as silver paste are used.

After die bonding, the wire-bonding process connects the chip to the lead frame with a thin gold wire. This allowed the chip to be wired through the lead frame.

-

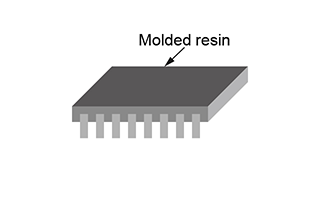

Molding: Chips are very delicate products that can be affected by scratches, shocks, dust, and magnetism. Therefore, the chip is encased in epoxy resin to protect it from external factors. This is called molding or packaging.

However, in recent years, smaller semiconductors have been required as the products have become smaller. The answer is bare dies, which are semiconductors that have not yet been packaged. The advantage of bare dies is that they can be stacked on a substrate in three dimensions; however, their chip yield is poor.

After dicing, wire bonding, and molding, semiconductor products undergo an inspection process before being shipped.

Matsusada Precision Technology in Back-End Process

-

Dicing: Wafer cutting requires very high precision. Matsusada Precision's high-performance high-voltage power supply can be used for high-precision wafer cutting. In plasma dicing, an electrostatic chuck is used to fix the wafer and a high-voltage power supply for the electrostatic chuck is necessary.

-

Wire bonding: Lead frames that are bonded to chips via wire bonding are electroplated. This improves the bonding between the wire and the frame. In electroplating, the metal to be plated is immersed in a plating solution and electricity is applied to deposit the metal in the solution on the surface of the metal to be plated. Matsusada Precision provides power supplies for the electroplating of lead frames.

-

Evaluation testing: The pre-shipment inspection process for semiconductor products includes dielectric breakdown testing, electrostatic discharge testing, and non-destructive X-ray testing. In a dielectric breakdown test, a high voltage is applied to the insulator or other material covering the semiconductor, and the voltage at which it is destroyed is measured.

When a human touches a product and an electrostatic discharge occurs, the product's durability is assessed using the electrostatic discharge test. The capacitor was charged with voltage and produced a quick pulse current during the static discharge test. Matsusada Precision provides high-voltage power supplies for dielectric breakdown and electrostatic discharge testing.

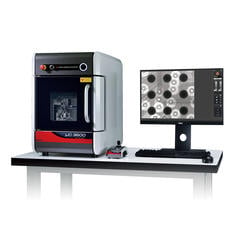

X-ray nondestructive inspection is an inspection in which an object is irradiated with X-rays to check its internal state, and it offers a line of X-ray transmission inspection systems that can be used for X-ray nondestructive inspection of semiconductors.

Reference (Japanese site)

- 日立ハイテク - 半導体製造工程

(https://www.hitachi-hightech.com/jp/products/device/semiconductor/process.html) - SEMI - イラストで分かる半導体製造工程

(https://www.semijapanwfd.org/manufacturing_process.html) - TEL(東京エレクトロン株式会社) - 半導体ができるまで - Precoess

(https://www.tel.co.jp/museum/exhibition/process/process7.html)

Related Technical Articles

Recommended products

Matsusada Precision's products meet the stringent specifications required by semiconductor manufacturing processes and are used throughout the fabrication process.