HIGH POWER, VERSATILE PROGRAMMABLE DC POWER SUPPLY

- Voltage range: 6 to 1500V

- Current: 1.2 to 1200A

- Power: 0.77 to 15kW

- Compact and high power

(Optional)

(Optional)

”Compact” “High power” “Multi-function” Programmable DC Power Supply with Superior Operability

REK series is high power / versatile DC programmable power supply that realizes Max. 2.5 kW by 1U (= 1.73 inches/44 mm) height, Max. 5.5 kW by 2U (= 3.5 inches/89 mm) height, Max.15.3 kW by 3U (= 5.24 inches/133 mm) height.

REK series is designed to achieve an excellent power factor as good as 0.99 *1, its high efficiency helps to reduce

environmental burden.

In addition, the series has a digital interface *2 such as LAN and USB as standard equipment and offers flexibility to easily support various automated measurements and large-scale system construction in production equipment.

We also have a lineup of REKJ series (0 to 650 V, 0.77 kW to 0.81 kW) in a half rack size of 8.35 inches/212 mm wide with

the similar functions to the REK series. (Optional to LXI compatible, some models to CE compatible)

- In single phase input models.

- Adaptors or options will be needed additionally.

FEATURES AND BENEFITS

- Compact and high power 15 kW

- Ideal for research and development with low noise switching method.

- PFC (Power Factor Correction) circuit and universal input wound not select the place of operation.

- Various operations by connecting multiple power supplies, such as master/slave, is possible.

- REK adopts large 4-digit monitor display for both voltage and current, which contributes to precise monitoring with better recognition.

- Operability and safety are improved with new features of two mode lock function and acceleration rotary encoder, which accelerate the output ramp up with the speed of rotating the encoder.

Models

- Half: half-rack width

: CE marking models and correspond to Low Voltage Directive and EMC Directive.

The model which attached -LEt option or -LMi option is out of CE marking acquisition. (Click here to learn more about options.)

This product is designed to be integrated into the customer's system and to meet the requirements of CE marking under the conditions of chassis mounting, noise suppression, proper protection, and isolation devices. It is not designed to perform alone.

PVCE series has CE-certified models. For more information, contact our sales representatives.

| Model | Maximum Output | ||

|---|---|---|---|

| Voltage | Current | Power | |

| HalfREKJ6-130 | 6 V | 130 A | 0.78 kW |

| REK6-200 | 200 A | 1.2 kW | |

| REK6-220 | 220 A | 1.3 kW | |

| REK6-310 | 310 A | 1.9 kW | |

| REK6-530 | 530 A | 3.2 kW | |

| REK8-180 | 8 V | 180 A | 1.44 kW |

| REK8-300 | 300 A | 2.4 kW | |

| REK8-600 | 600 A | 4.8 kW | |

| REK8-1000 | 1000 A | 8 kW | |

| HalfREKJ10-80 | 10 V | 80 A | 0.8 kW |

| REK10-150 | 150 A | 1.5 kW | |

| REK10-200 | 200 A | 2 kW | |

| REK10-240 | 240 A | 2.4 kW | |

| REK10-340 | 340 A | 3.4 kW | |

| REK10-510 | 510 A | 5.1 kW | |

| REK10-1000 | 1000 A | 10 kW | |

| REK10-1200 | 1200 A | 12 kW | |

| HalfREKJ15-54 | 15 V | 54 A | 0.81 kW |

| REK15-100 | 100 A | 1.5 kW | |

| REK15-160 | 160 A | 2.4 kW | |

| REK15-227 | 227 A | 3.4 kW | |

| REK15-340 | 340 A | 5.1 kW | |

| REK15-800 * | 800 A | 12 kW | |

| REK16-320 | 16 V | 320 A | 5.12 kW |

| REK18-290 | 18 V | 290 A | 5.22 kW |

| HalfREKJ20-40 | 20 V | 40 A | 0.8 kW |

| REK20-80 | 80 A | 1.6 kW | |

| REK20-125 | 125 A | 2.5 kW | |

| REK20-170 | 170 A | 3.4 kW | |

| REK20-200 | 200 A | 4 kW | |

| REK20-260 | 260 A | 5.2 kW | |

| REK20-420 | 420 A | 8.4 kW | |

| REK20-500 | 500 A | 10 kW | |

| REK20-600 | 600 A | 12 kW | |

| REK25-200 | 25 V | 200 A | 5 kW |

| HalfREKJ30-27 | 30 V | 27 A | 0.81 kW |

| REK30-53 | 53 A | 1.6 kW | |

| REK30-84 | 84 A | 2.5 kW | |

| REK30-115 | 115 A | 3.5 kW | |

| REK30-180 | 180 A | 5.4 kW | |

| REK30-240 | 240 A | 7.2 kW | |

| REK30-280 | 280 A | 8.4 kW | |

| REK30-333 | 333 A | 10 kW | |

| REK30-400 | 400 A | 12 kW | |

| REK35-45 | 35 V | 45 A | 1.6 kW |

| REK35-50 | 50 A | 1.75 kW | |

| REK35-72 | 72 A | 2.5 kW | |

| REK35-100 | 100 A | 3.5 kW | |

| REK35-155 | 155 A | 5.4 kW | |

| HalfREKJ36-22 | 36 V | 22 A | 0.79 kW |

| HalfREKJ40-20 | 40 V | 20 A | 0.8 kW |

| REK40-40 | 40 A | 1.6 kW | |

| REK40-60 | 60 A | 2.4 kW | |

| REK40-75 | 75 A | 3 kW | |

| REK40-85 | 85 A | 3.4 kW | |

| REK40-210 | 210 A | 8.4 kW | |

| REK40-250 | 250 A | 10 kW | |

| REK40-300 | 300 A | 12 kW | |

| HalfREKJ45-18 | 45 V | 18 A | 0.81 kW |

| REK45-35 | 35 A | 1.6 kW | |

| REK45-55 | 55 A | 2.5 kW | |

| REK45-78 | 78 A | 3.5 kW | |

| REK45-120 | 120 A | 5.4 kW | |

| REK54-100 | 54 V | 100 A | 5.4 kW |

| HalfREKJ60-13.5 | 60 V | 13.5 A | 0.81 kW |

| REK60-26 | 26 A | 1.6 kW | |

| REK60-30 | 30 A | 1.8 kW | |

| REK60-42 | 42 A | 2.5 kW | |

| REK60-60 | 60 A | 3.6 kW | |

| REK60-90 | 90 A | 5.4 kW | |

| REK60-140 | 140 A | 8.4 kW | |

| REK60-170 | 170 A | 10.2 kW | |

| REK60-200 | 200 A | 12 kW | |

| REK60-250 | 250 A | 15 kW | |

| REK70-30 | 70 V | 30 A | 2.1 kW |

| REK75-36 | 75 V | 36 A | 2.7 kW |

| HalfREKJ80-10 | 80 V | 10 A | 0.8 kW |

| REK80-20 | 20 A | 1.6 kW | |

| REK80-31 | 31 A | 2.5 kW | |

| REK80-45 | 45 A | 3.6 kW | |

| REK80-68 | 68 A | 5.4 kW | |

| REK80-110 | 110 A | 8.8 kW | |

| REK80-130 | 130 A | 10.4 kW | |

| REK80-190 | 190 A | 15.2 kW | |

| REK90-20 | 90 V | 20 A | 1.8 kW |

| REK100-16 | 100 V | 16 A | 1.6 kW |

| REK100-25 | 25 A | 2.5 kW | |

| REK100-36 | 36 A | 3.6 kW | |

| REK100-55 | 55 A | 5.5 kW | |

| REK100-85 | 85 A | 8.5 kW | |

| REK100-100 | 100 A | 10 kW | |

| REK100-150 | 150 A | 15 kW | |

| REK110-20 | 110 V | 20 A | 2.2 kW |

| HalfREKJ120-6.6 | 120 V | 6.6 A | 0.792 kW |

| REK120-13 | 13 A | 1.56 kW | |

| REK120-25 | 25 A | 3 kW | |

| REK125-65 | 125 V | 65 A | 8.1 kW |

| REK125-80 | 80 A | 10 kW | |

| REK125-120 | 120 A | 15 kW | |

| REK130-25 | 130 V | 25 A | 3.25 kW |

| REK150-10 | 150 V | 10 A | 1.5 kW |

| REK150-16.6 | 16.6 A | 2.5 kW | |

| REK150-24 | 24 A | 3.6 kW | |

| REK150-36 | 36 A | 5.4 kW | |

| REK150-55 | 55 A | 8.3 kW | |

| REK150-70 | 70 A | 10.5 kW | |

| REK150-100 | 100 A | 15 kW | |

| HalfREKJ160-5 | 160 V | 5 A | 0.8 kW |

| REK200-8 | 200 V | 8 A | 1.6 kW |

| REK200-12.5 | 12.5 A | 2.5 kW | |

| REK200-18 | 18 A | 3.6 kW | |

| REK200-20 | 20 A | 4 kW | |

| REK200-27 | 27 A | 5.4 kW | |

| REK200-42 | 42 A | 8.4 kW | |

| REK200-52 | 52 A | 10.4 kW | |

| REK200-75 | 75 A | 15 kW | |

| HalfREKJ250-3.2 | 250 V | 3.2 A | 0.8 kW |

| REK250-22 | 22 A | 5.5 kW | |

| REK250-34 | 34 A | 8.5 kW | |

| REK250-42 | 42 A | 10.5 kW | |

| REK250-60 | 60 A | 15 kW | |

| REK270-25 | 270 V | 25 A | 6.75 kW |

| REK300-5.3 | 300 V | 5.3 A | 1.6 kW |

| REK300-8.3 | 8.3 A | 2.5 kW | |

| REK300-12 | 12 A | 3.6 kW | |

| REK300-18 | 18 A | 5.4 kW | |

| REK300-28 | 28 A | 8.4 kW | |

| REK300-35 | 35 A | 10.5 kW | |

| REK300-50 | 50 A | 15 kW | |

| HalfREKJ350-2.2 | 350 V | 2.2 A | 0.77 kW |

| REK400-5 | 400 V | 5 A | 2 kW |

| REK400-22 | 22 A | 8.8 kW | |

| REK400-26 | 26 A | 10.4 kW | |

| REK400-38 | 38 A | 15.2 kW | |

| HalfREKJ500-1.6 | 500 V | 1.6 A | 0.8 kW |

| REK500-3.2 | 3.2 A | 1.6 kW | |

| REK500-5 | 5 A | 2.5 kW | |

| REK500-6 | 6 A | 3 kW | |

| REK500-7 | 7 A | 3.5 kW | |

| REK500-11 | 11 A | 5.5 kW | |

| REK500-17 | 17 A | 8.5 kW | |

| REK500-20 | 20 A | 10 kW | |

| REK500-25 | 25 A | 12.5 kW | |

| REK500-30 | 30 A | 15 kW | |

| REK600-4.1 | 600 V | 4.1 A | 2.5 kW |

| REK600-6 | 6 A | 3.6 kW | |

| REK600-9 | 9 A | 5.4 kW | |

| REK600-14 | 14 A | 8.4 kW | |

| REK600-18 | 18 A | 10.8 kW | |

| REK600-25 | 25 A | 15 kW | |

| HalfREKJ650-1.2 | 650 V | 1.2 A | 0.78 kW |

| REK650-2.5 | 2.5 A | 1.6 kW | |

| REK650-3.8 | 3.8 A | 2.5 kW | |

| REK650-5.5 | 5.5 A | 3.6 kW | |

| REK650-8.5 | 8.5 A | 5.5 kW | |

| REK650-13 | 13 A | 8.5 kW | |

| REK650-16 | 16 A | 10.4 kW | |

| REK650-23 | 23 A | 15 kW | |

| REK850-10 | 850 V | 10 A | 8.5 kW |

| REK850-12 | 12 A | 10.2 kW | |

| REK850-18 * | 18 A | 15.3 kW | |

| REK1000-15 * | 1000 V | 15 A | 15 kW |

| REK1500-10 | 1500 V | 10 A | 15 kW |

Discontinued models

Sales of the following models ended. We continue to support them.

| Model | Maximum Output | End of sales date | ||

|---|---|---|---|---|

| Voltage | Current | Power | ||

| Half REKJ800-1 | 800 V | 1 A | 0.8 kW | End of sales November 19, 2022. |

| REK600-2.7 | 600 V | 2.7 A | 1.6 kW | End of sales March 2, 2023 |

Functions

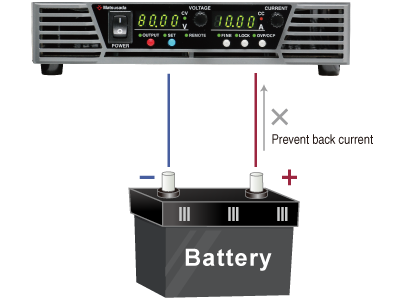

Sink Current Suppression

When supplying power to loads with capacities like batteries and capacitors, the sink current suppression is used to reduce the reverse current flowing from the load to the unit in order to prevent a voltage drop on the load as the output is OFF or the set voltage is lowered.

NOTE

It is not possible to stabilize the output by controlling back current. In case of load which has inverse voltage or over rated voltage, such as inductive load or regenerative motor, protect the power supply by adding dummy resister or diode to prevent back current.

Multi Setting Function

Function to memorize three different voltage and current settings in addition to standard preset function.

No need to adjust the output when different setting, and convenient function for production inspection process or testing which require frequent data taking.

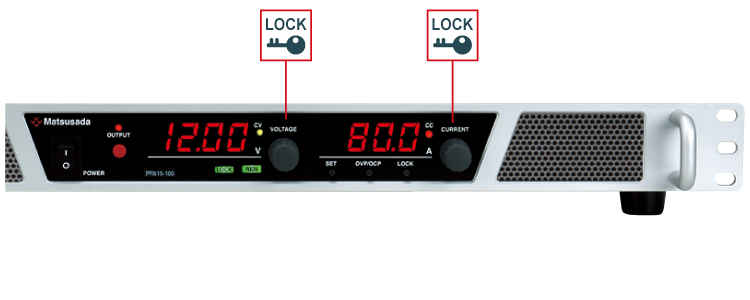

Two Mode Lock Function

Function to select two different lock modes for two different purposes."Full Lock" locks all the functions on the front panel, and "Normal Lock" locks all the functions except for ON/OFF switch. "Full Lock" mode shall be good in case mis-operation has to be completely avoided, and "Normal Lock" mode shall be good in case to avoid mis-operation but secure the way for emergency stop of power supply. You can select the best mode according to your level of "Security".

(In both modes, emergency stop is possible with Power Switch.)

Full LOCK

Lock all the functions other than reset lock mode. This mode is good for purpose. to avoid mis-operation completely

Normal LOCK

Lock voltage and current setting dial. This mode is good for purpose to avoid changing output settings by mistake or when easy emergency stop is required.

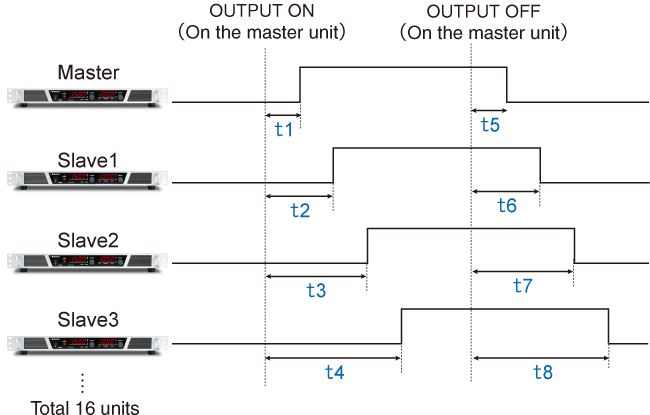

Delay Trigger Function

In case -LUs1, -LEt or -LGob option is selected, only one unit of REK/REKJ series can be used.

Function to delay the OUTPUT ON/OFF time. It is possible to use in case single unit of REK/REKJ series is used, and also when connecting several Matsusada Precision power supplies *1 using master-slave connection terminal*2 and output voltage/output current are set individually, delay trigger function can be used.*3

- R4K-36 series, R4K-80 series, RK-80 series, RK series, TB series and RKT series.

Detail datasheet for each model is available. Please contact nearby sales office. - Can be connected up to 16 pieces.

- Only for slave-local. In the case of slave remote control, exact same model of power supply need to be used. Also, in case of slave-local, each output voltage and current can be set individually. In case of slave-remote, output voltage and current can be set with one-control function which -each slave unit follows the master unit setting.

* t1 to T8 can be set in the range 0.0 to 99.9 s.

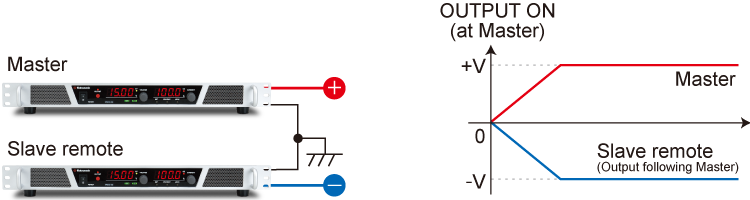

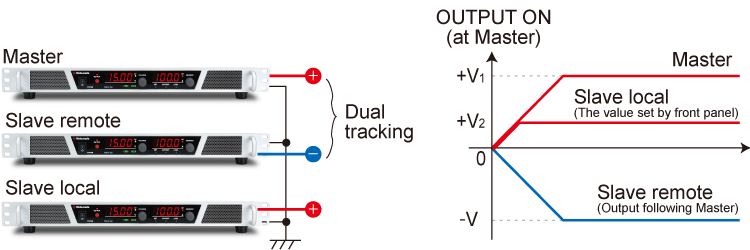

Dual Tracking, Multiple Outputs

Dual tracking control, which enables both positive and negative outputs simultaneously in master-slave operation, is possible. Multi outputs and various versatile operations are also possible by combining above dual tracking control and slave local mode. Positive and negative output (+V, -V) of dual tracking control and set output voltage of slave local mode can be output simultaneously by turning on the master unit.

- Please refer to Operation example.

- As for dual tracking control, models at output voltage exceeding 250 V are not available with the function.

Dual Tracking

Multiple Outputs

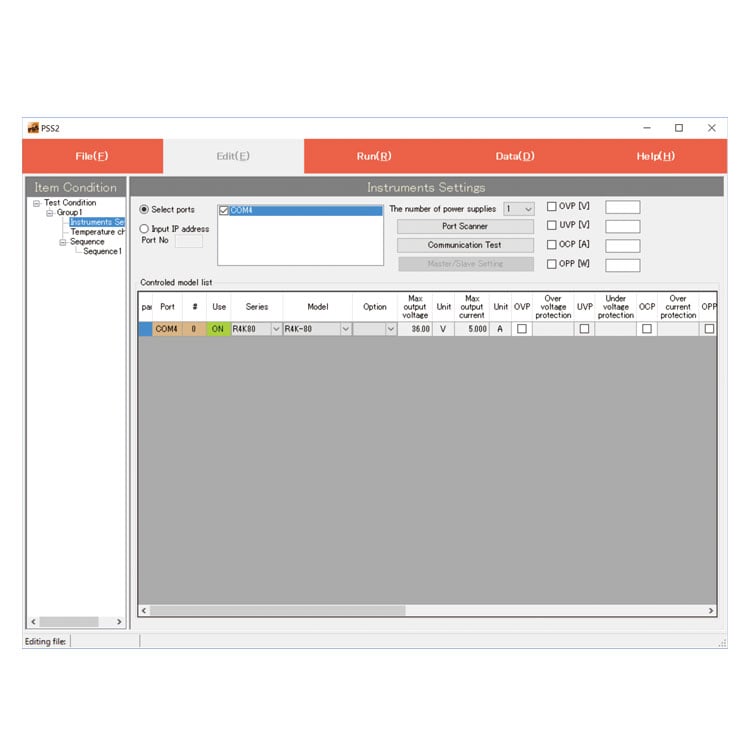

Digital Control Function

| Control Function | Output ON/OFF setting | |

|---|---|---|

| Display of various Status (fault/output/OVP/OCP/OTP/ACF/reverse sense connection/interlock) | ||

| Digital Control Max. 16 units (-LGob option models: Max. 32 units) |

||

| Package Control Multiple Units Hooked | ||

| Write Function | Setting Output Voltage/Setting Output Current | Percent Mode, Voltage or Current Value Mode |

| Setting OVP/Setting OCP | Percent Mode, Voltage or Current Value Mode | |

| Read Function | Measured Output Voltage/Measured Output Current | Percent Mode, Voltage or Current Value Mode |

| Setting Output Voltage/Setting Output Current | Percent Mode, Voltage or Current Value Mode | |

| Setting OVP/Setting OCP | Percent Mode, Voltage or Current Value Mode | |

Note: Minimum setting unit for each model is one count of the indicator.

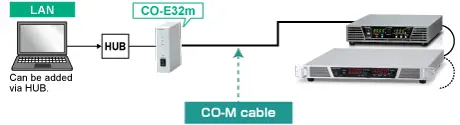

Digital Interface

This interface is Matsusada Precision's proprietary dedicated digital communication port.

This interface has modular type IN and OUT ports to allow daisy-chain connection.

Combined with an adapter (sold separately). Multiple power supplies can be controlled at once.

Adapters for LAN, USB, RS-232C, RS-485, and GPIB are available so that you can choose a suitable communication interface.

One-control operation by master/slave connection is also possible.

- As for 1U and 2U models, this function is not available when -LGob, -LUs1 or -LEt option is chosen.

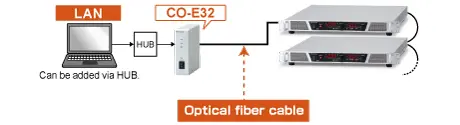

- When a noisy environment is presumed, the following -LGob option (optical interface) is required.

When a noisy environment is presumed, the following -LGob option (optical interface) is required.

External Analog Remote Control

-

External output ON/OFF

Output can be turned ON/OFF by relay or TTL signal.

Logic of OUTPUT can be made reverse. - Remote sensing Prevents voltage drop down (VO-VL) due to resistance (R) or deterioration of stability by contact resistance (Max compensation 0.5 V)

-

Remote/Local change

As for the output voltage control, output current control, overvoltage protection, and overcurrent protection, the remote/local mode can be individually switched by relay or TTL signal. - Output control (Voltage, Current, Overvoltage protection, Overcurrent protection)

- Output monitor (Voltage, Current)

- Status output

Specifications

Options

* These options cannot be selected together. Only one of each can be selected. Also, please see the CO/USB series datasheet for detail of function of the digital interface.

- -LDe

-

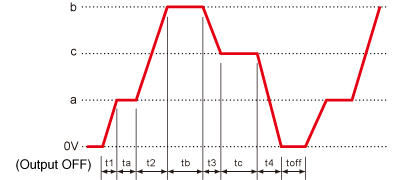

Pulse/Ramp sequence, Master follow function

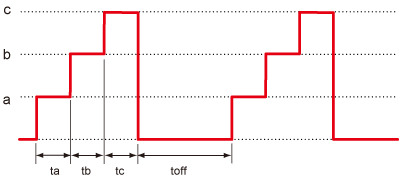

A. Pulse sequence

Using the stored voltage and current setting in each memory of a, b and c and multi-set function, sequence operation is possible. The setting of repetition to say nothing of continuous driving can be set. Various different operations, such as repetition of memory a and b or b ,c and off, are possible by setting the set time of memory a, b, c, and/or off to be 0.0. Thus, it makes this model suitable for evaluation test or other applications.

ta, tb, tc and toff can be set with range 0.0, 1.0s to 99.9 h respectively.

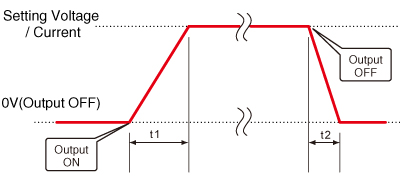

B. Ramp

This function controls the ramping up and down the voltage and current to the set value (or from set voltage and current value to 0 V/0 A). It is convenient to increase (decrease) the voltage and current value slowly.

- The Ramp sequence can be selected from [both set voltage and current], [only set voltage], and [only set current].

- Master follow function cannot be used with -LGob, -LUs1, and -LEt option.

t1 and t2 can be set with a range of 0 to 999 s respectively.

C. Combination of pulse and ramp sequence

Features of pulse sequence operation and ramp sequence operation can be combined for more convenient operation. In addition, by adding multi-set function, sequence operation can be operated using stored voltage and current settings in each memory. The setting of repetition to say nothing of a continuous driving can be set. For example it is possible to slowly ramp up and down the voltage and current to the three different settings, and so, it is useful on various scenes.

t1, t2, t3 and t4 can be set with range 0 to 999 s respectively.

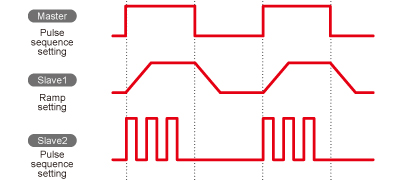

ta, tb, tc and toff can be set with range 0.0 s, 1.0 s to 99.9 h respectively.D. Master follow

When the pulse sequence operation and the ramp work master/slave, the output signal to the slave unit is transmitted. The slave unit can be output in an output status different from the master unit.

- The Ramp sequence can be selected from [both set voltage and current], [only set voltage], and [only set current].

- The master follow function is only available with the standard interface.

Note: The operation accuracy of the timer when sequencing is 0.5%. Be careful when you use it by the long-term running operation.

- -LEt *

-

LAN interface

The option is included in the -LMi option although it can be manufactured. For more information about this option, feel free to contact us.-LEt optional models do not have CE marking.

- -LGob *

-

Optical interface

This option changes the standard interfaces to built-in optical interface port.

By combining this option with an adapter for optical connection (sold separately), communication between the control device and the power supply can be controlled in an isolated state. Be sure to select this option when using the product in the following environments.- -LGob: Optical interface port + optical cable 2 meters

- -LGob(Fc5): Optical interface port + optical cable 5 meters

- -LGob(Fc10): Optical interface port + optical cable 10 meters

- -LGob(Fc20): Optical interface port + optical cable 20 meters

- -LGob(Fc40): Optical interface port + optical cable 40 meters

- Select the optional optical interface board (-LGob) when using this DC power supply under the following conditions.

-

- Noisy environments such as factories (example: when motors or coils are used near loads or power sources).

- If this power supply and your controller (PC or PLC) cannot be installed within 2 meters.

- When there is a possibility of arcing or output short-circuit.

- -LMi *

-

Multi-digital interface

Digital control by LAN, USB (TMC), and RS-485 (Multidrop) is available. (These simultaneous use is impossible. And, RS-485 supports only FULL DUPLEX communications.) This option includes -L(SCPI) option, and attaches IVI driver corresponding to SCPI command. It makes it easy for control program development with various programming languages such as LabView, VisualBasic and C#, etc.-LMi optional models do not have CE marking.

- -LUs1

-

USB interface

The option is included in the -LMi option although it can be manufactured. For more information about this option, feel free to contact us.

- -L(Mc0.5), -L(Mc0.15) *

-

Communication cable extension

The length of CO-M cable will be 0.5 meters long 0.15 meters long. (You can choose only either.)

- -L(SCPI)

-

SCPI command

Enable control via SCPI command.

- -L(400V), -L(480V), -L(3P), -L(1P)

-

Input voltage/phase

For details, download the datasheet below.

These optional models do not have CE marking.

How to Order

When ordering, add Option No. in the following order by alphabet, and input voltage to Model No. Example: REKJ6-130-LDeMi(Mc0.5), REK100-36-LDeGob(Fc20)(1P), REK500-11-LDeMi(400V), (Alphabetical, AC input numeral order)

Accessories

| Sold separately 1.2 kW to 2.5 kW model 2.7 kW to 3.6 kW single phase input model |

CABLE TYPE5 | 300 V / 25 A For Japan or North America |

2.5 meters | ||

|---|---|---|---|---|---|

| Sold separately 1.75 kW to 2.5 kW three-phase input model 2.7 kW to 5.5 kW model |

CABLE TYPE6 | 600 V / 25 A For Japan |

2.5 meters | ||

| Sold separately 6.75 kW to 15.3 kW model |

CABLE TYPE7 | 600 V / 75 A For Japan |

10 meters |

| Standard for 100 V input, 3-pin plug |

CABLE TYPE8 | 125 V / 125 A For Japan or North America |

2.5 meters Fixed length |

||

|---|---|---|---|---|---|

| Sold separately for 200 V input, flying lead |

CABLE TYPE3 | 250 V / 10 A For Europe |

2.5 meters Fixed length |

||

| Sold separately for 200 V input, 2-pin plug |

CABLE TYPE4 | 250 V / 10 A For Europe |

2.5 meters Fixed length |

- Use an AC cable that is suitable for your usage environment and region.

Please note that other than AC input cables that correspond to the following are to be prepared by customers. - To order 2.5 meters or longer, add the length (meters) to the model No.

<Example> 5 meters : CABLE TYPE 5 (5)

Digital Interface

Enable digit control via LAN/USB/RS-232C/RS-485/GPIB as well as one control with master/slave.

Adapter for digital interface

To use the optical interface, you need to prepare an optical interface adapter separately. The following interface adapters are available according to your controller port.

- CO-E32m: LAN adapter

- CO-U32m: USB adapter

- CO-MET2-9: RS-232C (9 pin) adapter

- CO-MET2-25: RS-232C (25 pin) adapter

- CO-MET4-25: RS-485 (25 pin) adapter

- CO-G32m: GPIB adapter (Discontinued in December 2028)

Example of communication with a digital adapter

For details, refer to CO/USB series

Optical isolation adapter

To use the optical interface, you need to prepare an optical interface adapter separately. The following interface adapters are available according to the communication method of your controller port.

- CO-E32: LAN to optical interface adapter

- USB-OPT: USB to optical interface adapter

- CO-OPT2-9: RS-232C (9 pin) to optical interface adapter

- CO-OPT2-25: RS-232C (25 pin) to optical interface adapter

- CO-OPT4-25: RS-485 (25 pin) to optical interface adapter

- CO-G32: GPIB to optical interface adapter (Discontinued in December 2028)

Example of communication with optical fiber

Dimension

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

REK/REKJ series Datasheet

Date: 2024-04-23 rev.42

PDF (3,876 KB)

-

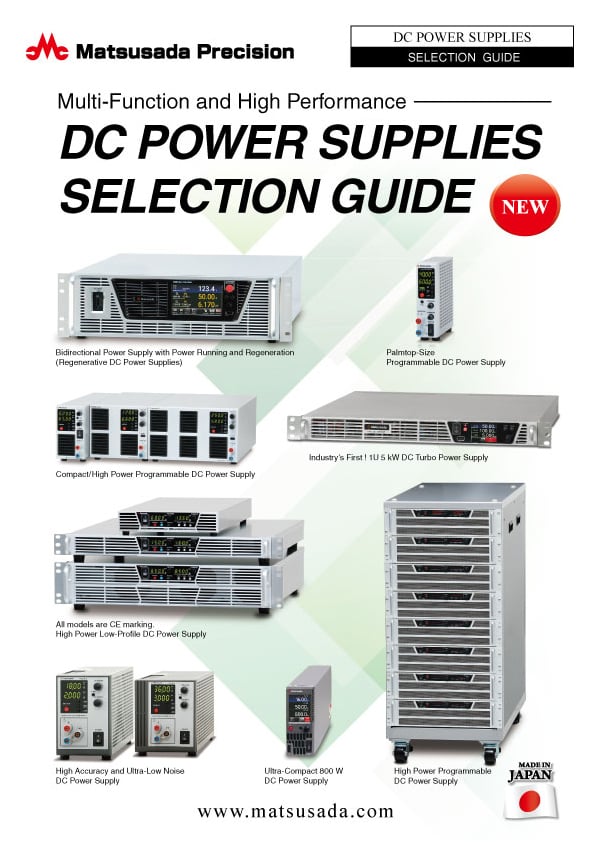

DC POWER SUPPLIES SELECTION GUIDE

Date: 2023-12-06 rev.00

PDF (1,202 KB)

-

How to Use DC Power Supplies

Date: 2024-03-05 rev. 08

PDF (1,467 KB)

-

RK/REK/REKJ series Basic Instruction Manual

Date: 2022-7-8 rev.0.5

PDF (445 KB)

-

RK/REK/REKJ series Instruction Manual

Date: 2022-6-22 rev.2.0

PDF (2,942 KB)

-

REK/REKJ series Instruction Manual (LMi option)

Date: 2021-01-15 rev.0.7

PDF (1,261 KB)

-

REK/REKJ series IVI Driver (LMi option)

Date: 2020-12-17 rev. 02

ZIP (9,306 KB)

-

REK/REKJ series USB Driver

Date: 2023-08-23 rev1.7.5

ZIP (6,617 KB)

-

RK/REK/R4G series USB Driver (LMi option guide)

Date: 2020-07-02 rev0.0

PDF (152 KB)

The account registration is necessary for downloading

-

REK/REKJ series Datasheet

Date: 2024-04-23 rev.42

PDF (3,876 KB)

-

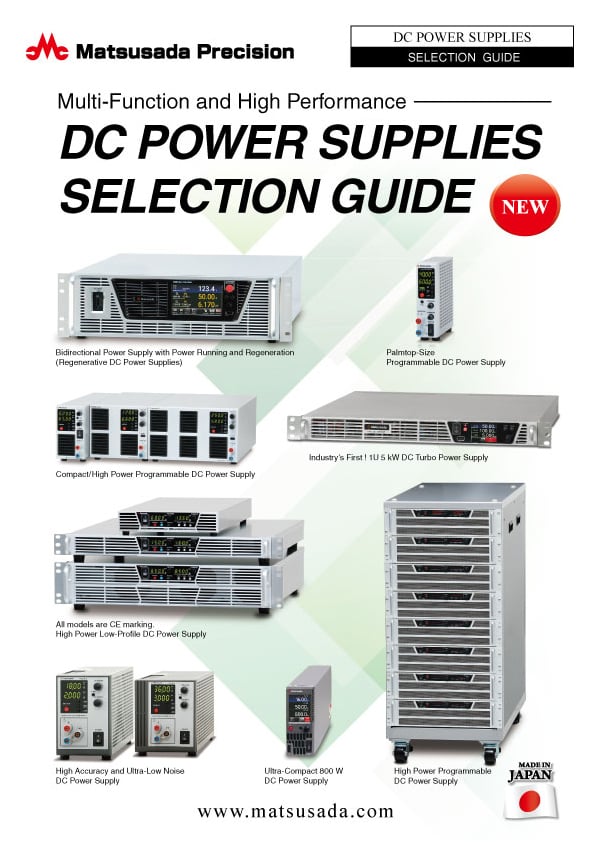

DC POWER SUPPLIES SELECTION GUIDE

Date: 2023-12-06 rev.00

PDF (1,202 KB)

-

How to Use DC Power Supplies

Date: 2024-03-05 rev. 08

PDF (1,467 KB)

-

RK/REK/REKJ series Basic Instruction Manual

Date: 2022-7-8 rev.0.5

PDF (445 KB)

-

RK/REK/REKJ series Instruction Manual

Date: 2022-6-22 rev.2.0

PDF (2,942 KB)

-

REK/REKJ series Instruction Manual (LMi option)

Date: 2021-01-15 rev.0.7

PDF (1,261 KB)

-

REK/REKJ series IVI Driver (LMi option)

Date: 2020-12-17 rev. 02

ZIP (9,306 KB)

-

REK/REKJ series USB Driver

Date: 2023-08-23 rev1.7.5

ZIP (6,617 KB)

-

RK/REK/R4G series USB Driver (LMi option guide)

Date: 2020-07-02 rev0.0

PDF (152 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.