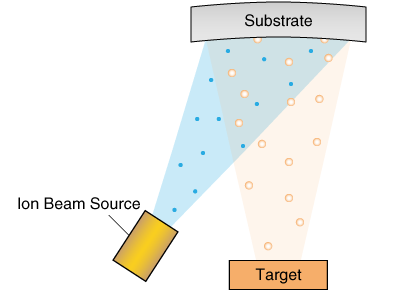

Ion beam deposition (IBD) is a thin-film deposition technique in which source material is ionized, accelerated by an electric field, and deposited onto a substrate to form a thin film. Typically used cluster-ion beam deposition produces excellent films with good crystalline properties.

Clusters are aggregates of tens to thousands of atoms or molecules. When formed from a gas source, they are referred to as gas clusters. Gas clusters are generated when a high-pressure gas expands through a nozzle into a high-vacuum chamber. This process, known as adiabatic expansion, causes the gas to cool and condense into clusters. The generated clusters are then ionized, typically by electron impact.

This method involves bombarding the clusters with high-energy electrons, which strips electrons from the clusters, leaving them with a net positive charge. An electric field then accelerates these ionized clusters toward a substrate. This technique is used for applications such as high-quality thin-film deposition and surface modification.

Power supplies are a core component in ion beam deposition systems, crucial for functions such as ion beam acceleration, extraction, suppression, deflection, grid voltage, and neutralization. Matsusada Precision offers a wide range of power supplies to meet these demanding applications.