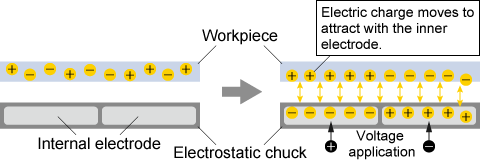

An electrostatic chuck (E-Chuck or ESC) is a device that holds and secures a workpiece using electrostatic force. When a voltage is applied to electrodes embedded within the chuck, it induces charge separation in the workpiece. This creates a strong attractive Coulomb force between the workpiece and the chuck surface, holding it firmly in place.

Electrostatic chucks are divided into two types based on their chucking method. One is the Coulomb force type, which uses an insulating material as the dielectric. The other is the Johnsen-Rahbek (JR) type, which uses a slightly conductive dielectric material. A small leakage current flows across the interface between the workpiece and the chuck, generating a powerful attractive force through electrostatic polarization. The Coulomb-force type is the more prevalent of the two, accounting for approximately 60% of ESC applications.

Since electrostatic chucks do not require mechanical clamps, they are suitable for gripping very delicate workpieces such as silicon wafers, metal foils, and films. For this reason, they are used in semiconductor manufacturing equipment to transport wafers and to hold them securely in place during processing.

Electrostatic chucks are also essential components in Critical Dimension Scanning Electron Microscopes (CD-SEM) and Defect Review SEMs (DR-SEM) employed for inspection during semiconductor manufacturing. In these SEMs, a retarding field method is sometimes employed. This technique involves applying a high negative voltage to the E-Chuck to decelerate the primary electron beam just before it impacts the wafer. This reduces beam-induced damage and charging effects, enabling high-resolution imaging at low landing energies.

Matsusada Precision manufactures a comprehensive lineup of high-voltage power supplies, including specialized models for electrostatic chucks. Our products are compatible with both Coulomb force and Johnsen-Rahbek (JR) types. We also offer custom-designed solutions tailored to specific customer requirements. Please contact us for more information.

Applications of electrostatic chucks:

- Semiconductor Fabrication Equipment

- Photolithography

- Semiconductor Wafer Handling

- Chemical Vapor Deposition (CVD)

- Plasma Enhanced CVD (PECVD)

- Inductively Coupled Plasma CVD (ICPCVD)

- Ion Beam Deposition (IBD)

- Atomic Layer Deposition (ALD)

- Dry Etching

- Plasma Etching

- Reactive-ion Etching (RIE)

- Atomic Layer Etching (ALE)

- Flat Panel Handling

Electrostatic Chuck Manufacturers

- SHINKO Electric Industries - Ceramic Electrostatic Chuck

- Sumitomo Osaka Cement - High Performance Electrostatic Chucks

- NGK INSULATORS - Electrostatic chucks

- TOTO Ltd - Electrostatic Chucks

- NTK CERATEC - Electrostatic chuck

- Kyocera Corporation - Electrostatic Chucks (ESCs)

- Related Terms:

-

- electrostatic chuck

- Coulomb force

- Johnsen-Rahbek

- wafer transfer

- semiconductor manufacturing equipment

- semiconductor wafer chucking