"On-site operating" X-ray inspection system in pursuit of simple operation

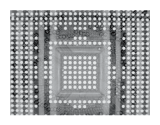

A work can be made to move to the position that you want to inspect quickly by a hand-operated multi-lever. Since short-circuit, lack, etc. of BGA are observable, it is most suitable for an inspection on the spot. In addition, we realize the price that it is easy to introduce while consisting of "Clear inspection image" "High operability" "High safety" by reviewing a function and a design thoroughly.

Features and Benefits

- Compact design of the desk-top size

- In order not to choose a setting position in the compact size of W: 18.9 inches (480 mm) × D: 20.3 inches (515 mm) × H: 20.7 inches (525 mm), it is ideal for use on the spot.

- Equipped with 2-inch x-ray camera

- A high-resolution and compact X-ray camera enables you to make a feeble transmission X-ray a visible image.

- The thorough pursuit of safety

- Because it is shipped with an interlock function to stop x-ray radiation immediately when a stage is opened suddenly, you can use it in comfort.

Model

| Model | X-ray Source | Imaging Section | Stage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube voltage | Tube current | Focal spot size | Size of visual field | Number of valid pixel | Output signal from camera*1 | Inspection viewing field | Max.size of sample | X-axis travel | Y-axis travel | Rotation angle *2 | |

| μB3000 | 20 to 60 kV | 0.05 to 1 mA | 50 µm | 2 inches | 640 x 480 pixels | EIA/NTSC method | 1.42 x 1.06 inches (36 x 27 mm) | X 10.24 x Y 7.87 inches (X 260 x Y 200 mm) |

4.72 inches (manual) | 7.87 inches (manual) | 360° (manual) |

Functions

Overwhelming excellent usability!

Easy alignment

The position of a work can be decided immediately.

By a hand-operated multi-level, since a stage can be quickly moved to the X-axis direction of 4.72 inches (120 mm), the Y-axis direction to 7.87 inches (200 mm), the part that wants to see work is correctly observable.

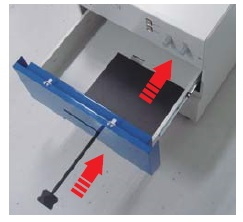

Easy setting work on the stage

Since it is a door of a drawer system and a large stage, the set of a work is also simple.

Since a service outlet is equipped on the rear panel standardly, it is convenient when using a beacon light, etc. together.

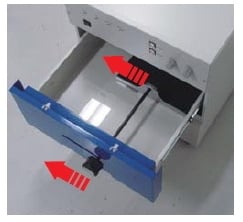

Easy maintenance

Accessible to X-ray tube simply by removing two screws.

Exchange and various maintenances of an X-ray tube can be easily performed only by removing a top plate.

Software

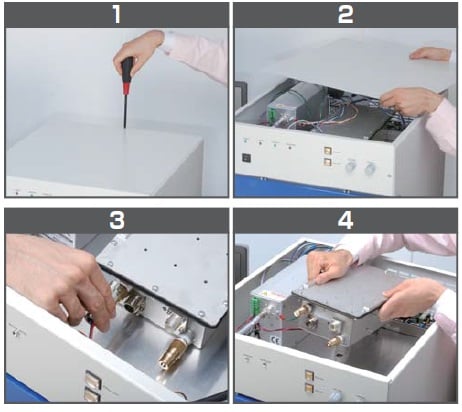

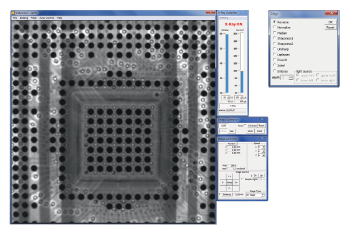

Dedicated software for capturing images, µRay Vision

Image processing software with the measurement function

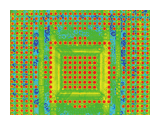

µRay Vision, the application software of our X-ray inspection systems offers easy operation with the X-ray control. Furthermore, in addition to the average integration of images, the software features the COLORING function where the color is added to certain areas with arbitrary brightness levels.

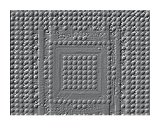

- (1) High-definition imaging

- Allows high-definition images to be displayed in real-time.

- (2) X-ray controller

- Allows you to turn the X-ray source on and off and to control the tube voltage and current.

- (3) Image controller

- Allows you to configure the image capture settings, including the moving-image filter and display range settings.

- (4) Stage controller

- Allows you to operate the stage using a mouse.

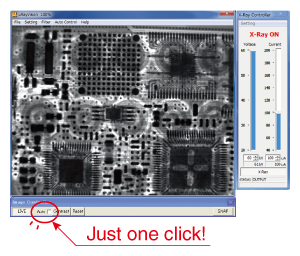

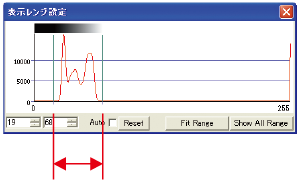

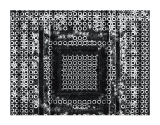

Automatic contrast adjustment function

Invisible images are automatically arranged in contrast to make them visible.

Besides, the histogram display and the manual operation of contrast adjustment are available in this window.

Filters function

The µB3000 supports 10 or more types of filtering and image processing allowing detailed image analyses. Images can be analyzed in real-time by performing appropriate filtering for displaying moving images.

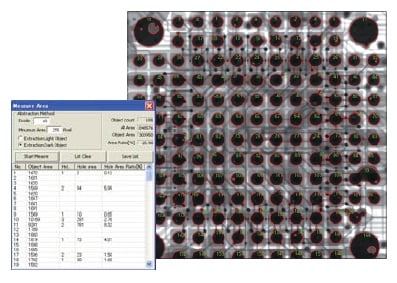

Measuring areas

The µB3000 can measure the areas, number of holes, area of holes, and area ratio of an object in a shot image.

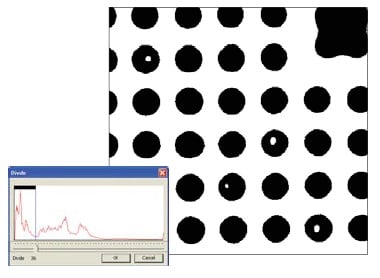

Binarizing processing

A shot image can be displayed in a binary manner by contrast by setting a threshold and binarizing the image.

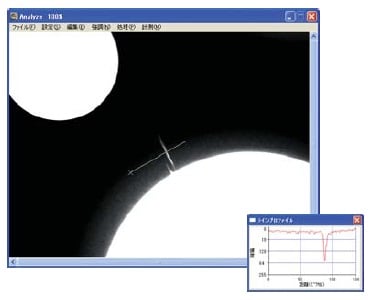

Measuring line profile

This function measures the line profile between two points on the monitor screen and displays a graph.

Specifications

Accessories

- STG002: Height Adjustment Stage (Size: 120 mm×120 mm)

- STG056: Height Adjustment Stage (Size: 120 mm×140 mm)

- The stage helps you to raise its height. Therefore, the sample can be closer to the X-ray camera for shooting so you can take larger field images.

- XDSK200: Aluminum table for option

Application

Fields and Applications of X-ray Radiography Non-Destructive Testing

- Pharmaceuticals and Cosmetics

- Tablets, Capsules, Catheters, Medical pouches, Foreign objects in the face mask, Cosmetics

- Automobiles and Electric Vehicles

- Automotive components, Wire harness, Batteries, Molded plastic parts, Motor, Insert molded parts, Aluminum die casting, Sensor, Mating parts connection

- Electronics

- Ball grid array (BGA), Integrated circuit (IC) chip, Connectors, Capacitors, LED, Relays, Printed circuit board (PCB), AC adapter, Light bulbs filament, Electrical cable disconnects, Discharge traces of dielectric breakdown

- Advanced Materials

- Carbon-Fiber-Reinforced Polymers (CFRP), Insulation material, Carbon, Dissimilar material joint, Contamination in beryllium

- Precision Conponents

- Probe, Bearing, Mating of plastic parts, Spring position

- Creatures and Plants

- Laboratory rats, Seeds, Flowers, Shell, Bone, Insects, Rice

- Others

- Microscopic foreign matter contamination, Voids in welding, Plastic bottle, Sealing of cans

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

μB3000 Datasheet

Date: 2022-8-17 rev.04

PDF (2,710 KB)

Login Required

-

μB3000 Datasheet

Date: 2022-8-17 rev.04

PDF (2,710 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.