Benefits of X-Ray CT system

- Observation from multiple directions

- Non-contact measurement

- Distance measurement

- Volume measurent

- Rendering object properties

- Utilized for reverse engineering

- Contributing to product development(speedy visualization of defects)

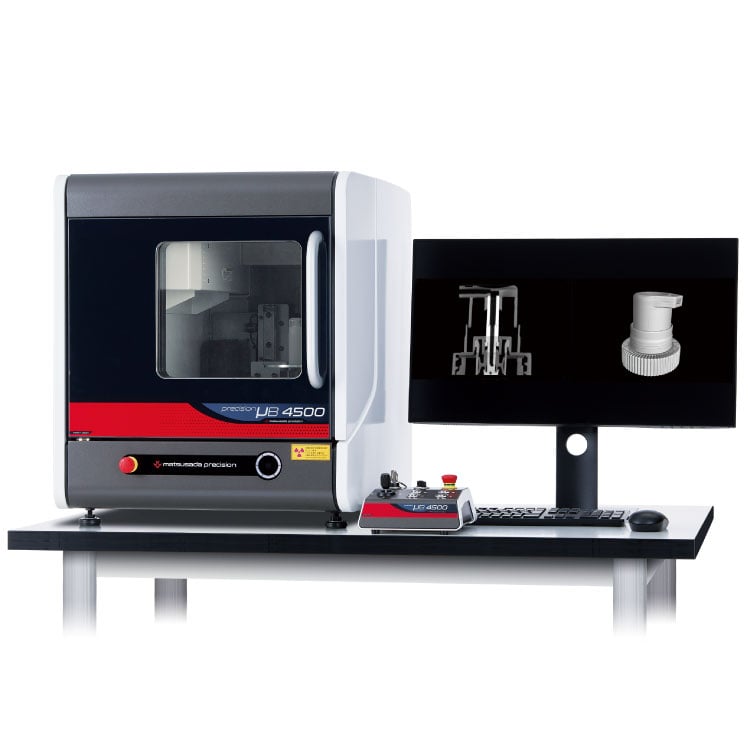

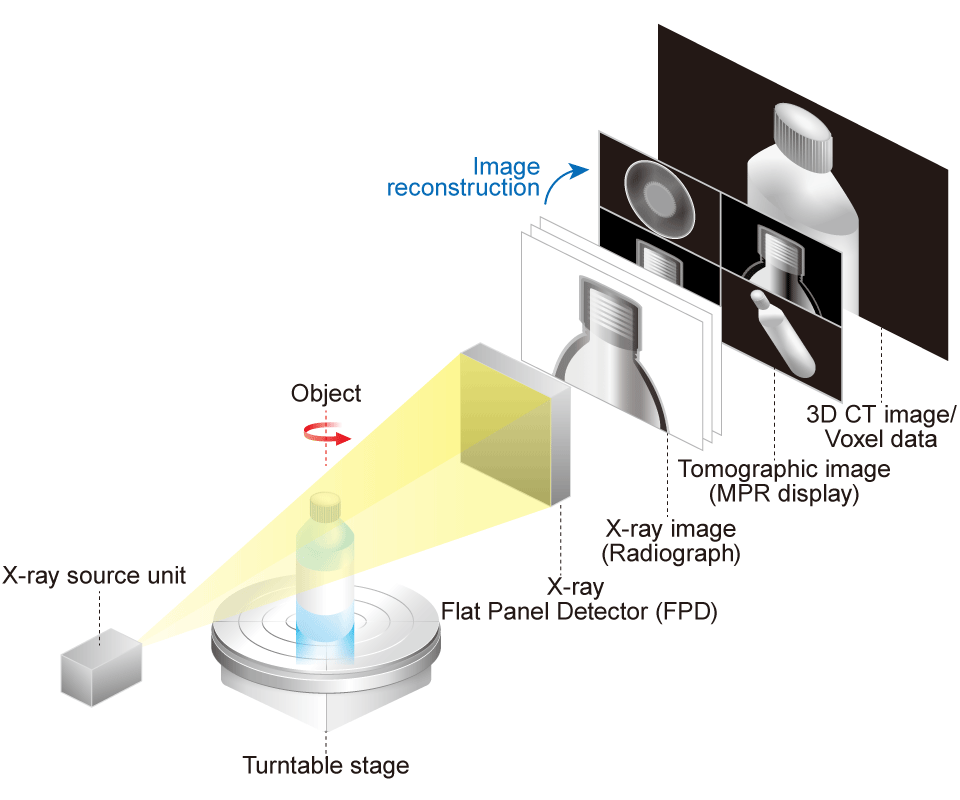

Computed Tomography Basics

Computed Tomography (CT) refers to non-destructive testing (NDT) technology that uses an X-ray generator and an X-ray detector (camera). The CT scan generates two-dimensional (2D) vision images of objects from many different angles with a full 360-degree rotation. Using the reconstruction software, you can reconstruct the tomographic images of the objects and convert them to three-dimensional images.

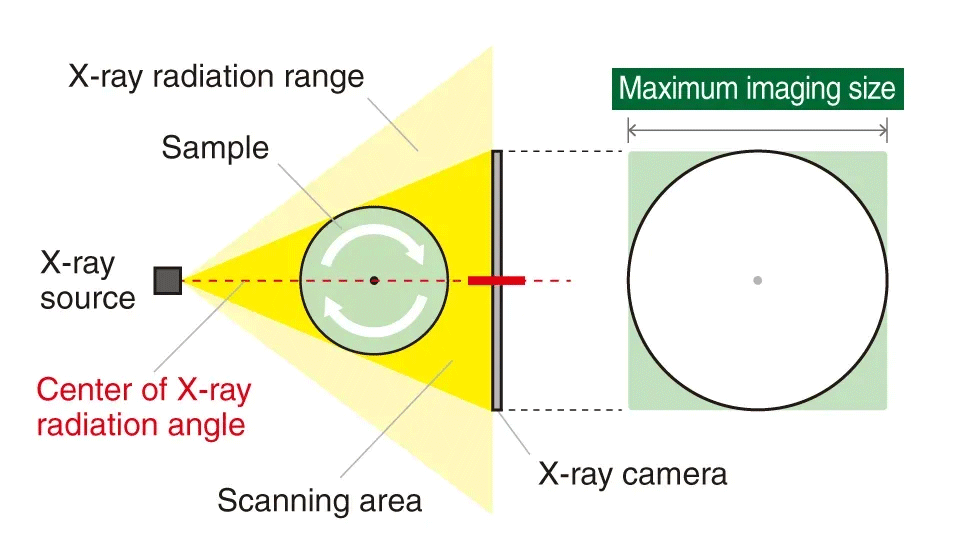

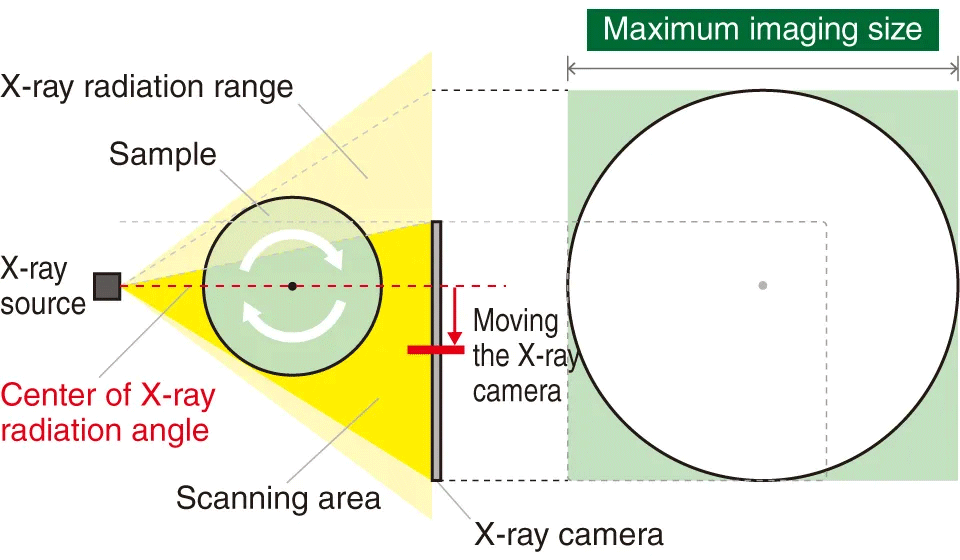

Normal scan vs Offset scan

In a Normal scan, if the width of the vision image of the sample is larger than the width of the X-ray camera, you need to shoot the sample repeatedly to obtain the tomographs. On the other hand, using offset scan, the center of the X-ray camera is shifted from the center of rotation of the sample for shooting, so a tomograph of a wide area at a time can be taken.

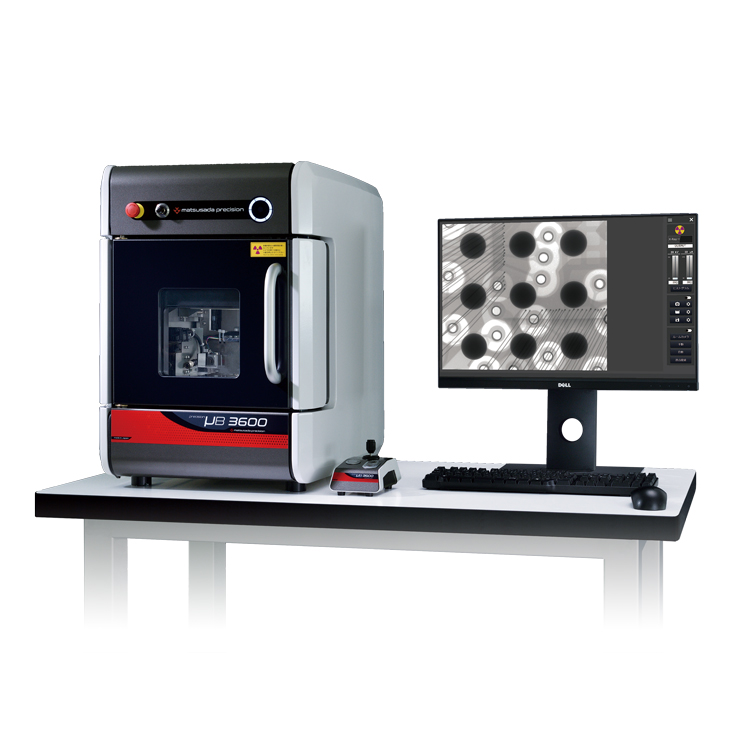

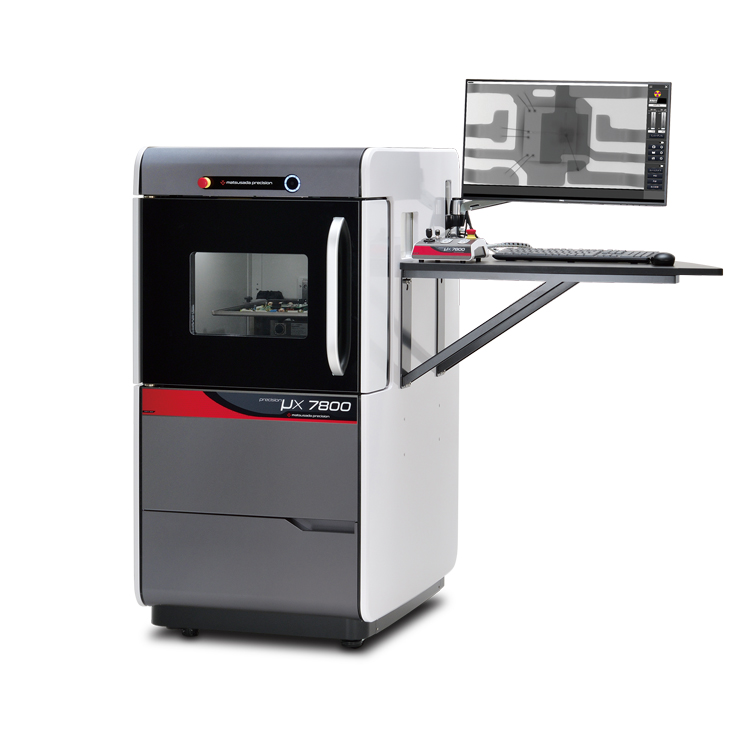

Lineup

| Function | -CTN | -CTDa | -CTM | CTDaX | ||

|---|---|---|---|---|---|---|

| Scan mode | Normal scan | |||||

| Half scan | ||||||

| Offset scan | ||||||

| Reconstruction | Noise suppresion | |||||

| Metal artifact reduction | - | - | ||||

| Beam hardening reduction | - | - | ||||

| Ring artifact reduction | - | - | ||||

| Simple analysis | Volume rendering | |||||

| 2D Cross-section surface display | ||||||

| MPR image display | ||||||

| 3D tomographic image | - | |||||

| Measurement | Dimension (distance) measurement | |||||

| Angle measurement | - | - | ||||

| 2D/3D internal diameter measurement | - | - | ||||

| 3D fitting | - | - | ||||

| 3D Particle analysis | - | - | ||||

| 3D drawing | - | - | ||||

| Saving in DICOM format | - | - | ||||

*precision CT9600 has the -CTDa feature as standard, and selectable -CTDaX as an option.

Functions

RECONSTRUCTION

Ring artifact reduction

The filtering process can reduce artifacts in two-dimensional tomographic images.

- -CTN

- -CTDa

- -CTM

- -CTDaX

Metal artifact reduction

The function reduces metal artifacts in the captured tomographic images.

It provides tomographic images with reduced metal artifacts for structural image analysis and internal observation.

- -CTN

- -CTDa

- -CTM

- -CTDaX

2D IMAGE

Here is an observation example of a capacitor (size approximately 0.24 inches (6 mm) in diameter, 0.39 inches (10 mm) in height.

- -CTN

- -CTDa

- -CTM

- -CTDaX

Arbitrary tomographic images

Displays tomographic images at arbitrary position.

Multi Planar Reconstructions (MPR)

Displays tomographic images of the 3D volume data from three directions.

3D IMAGE

- -CTN

- -CTDa

- -CTM

- -CTDaX

3D arbitrary tomographic images

Visualizes volume-rendered 3D tomographic images.

Volume rendering

Displays images that are generated from voxel data with all XYZ information. By changing the viewpoint, images from all directions can be displayed.

ANALYSIS FUNCTION

Dimension measurement

Measures dimensions between specified points on a 2D image. (The -CTN option is only available for 2D images.)

- -CTN

- -CTDa

- -CTM

- -CTDaX

Volume / Surface area measurement

Measures the volume or surface area of a read 3D image.

- -CTN

- -CTDa

- -CTM

- -CTDaX

Shortest distance measurement

Measures the shortest (or longest) distance on a 2D image. The distance is automatically measured by mouse dragging, and the dimensions display the dimensions of the shortest and longest parts. The measurement results are reflected in a 3D image.

- -CTN

- -CTDa

- -CTM

- -CTDaX

Arbitrary object separation

Arbitrarily extracts some part of an image to color or separate it.

- -CTN

- -CTDa

- -CTM

- -CTDaX

CAD data output

The surface shape of 3D images can be approximated polygonally to output as a point group file (STL format).

- -CTN

- -CTDa

- -CTM

- -CTDaX

Geometric Dimensioning and Tolerancing (GD&T)

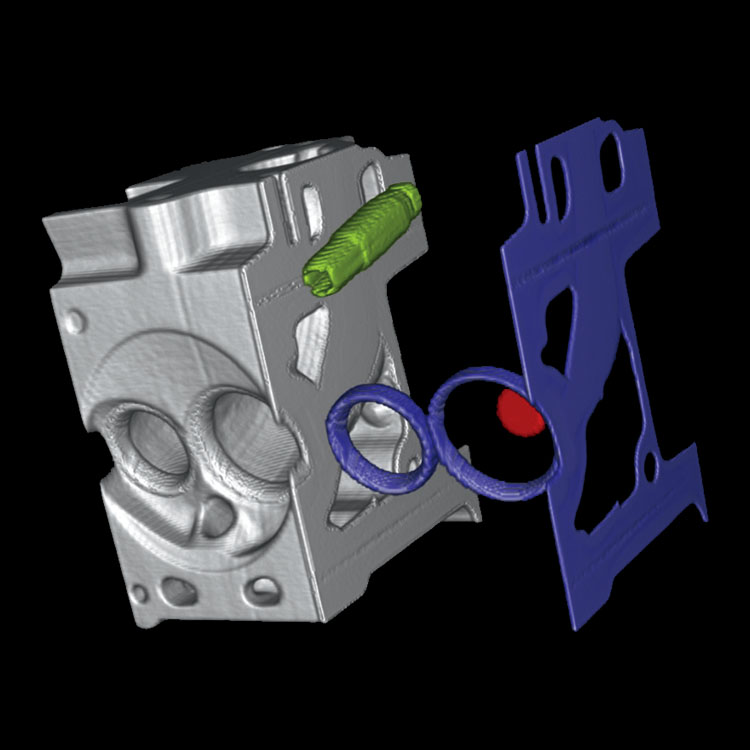

Using 3D display analysis data, you can check areas of sample structure, foreign matters, or shrinkage cavities in molding that cannot be measured by contact-type instruments. In addition, the function visualizes deviations and defect locations, facilitating sample inspection. It is suited for mold designs and inspections of shrinkage cavities in casting.

Comparison of design values and actual measured values

Visualization is available for shape differences by comparing CT data as the measured values and CAD data as the design values. Deviations can be identified by color.

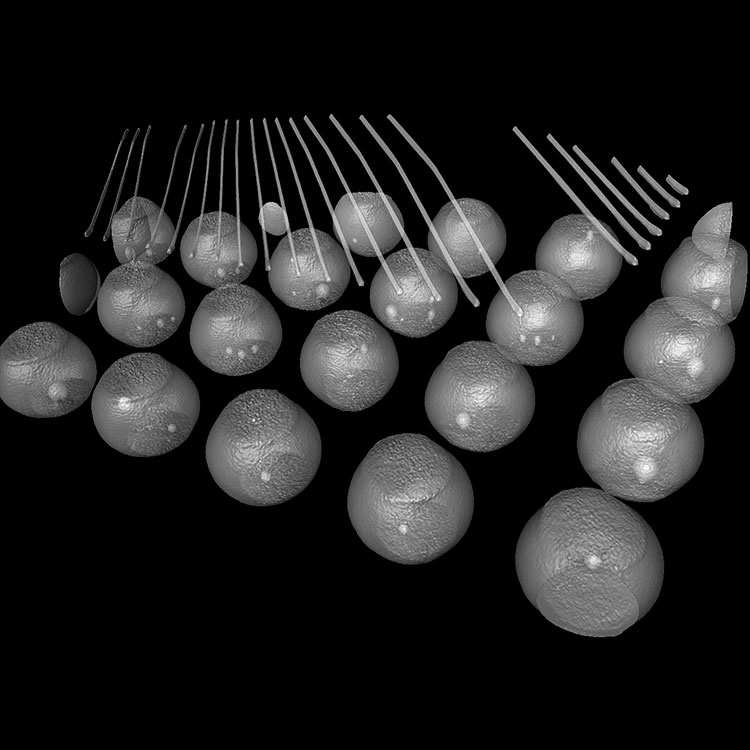

Defect analysis

The defect analysis is used for detecting accurate location and size of defects in samples. It can also calculate the percentage of defects to the sample volume. It is available in the following categories.

- Scale (circumscribed sphere) / Volume

- Surface area

- Position xyz

- Self - Sphericity

- Spacing (distance between defects)

- Projected size xyz

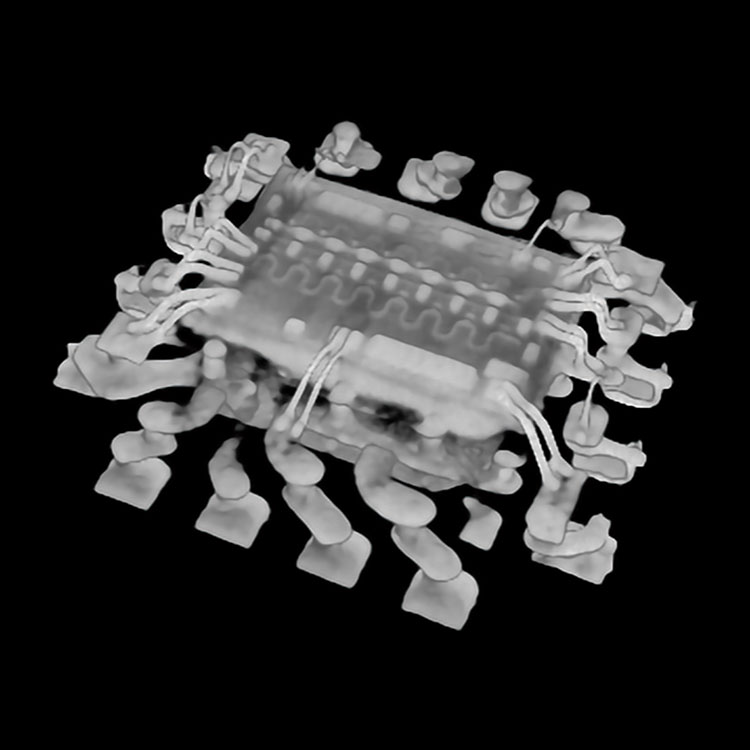

Wall thickness analysis

Visualization of wall thickness analysis using CAD data and CT data is available. It is also available for errors in design values. The errors can be identified by color.

Wall thickness analysis (2D-display)

Three-dimensional images are used for the wall thickness measurement.

Specifications

Applications

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

Micro View X-Ray CT System Guide

Date: 2023-08-04 Rev.04

PDF (9,169 KB)

Login Required

-

Micro View X-Ray CT System Guide

Date: 2023-08-04 Rev.04

PDF (9,169 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.