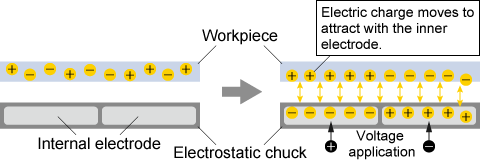

An electrostatic chuck (E-Chuck, ESC) is a chuck that absorbs and fixes (chucks) a workpiece by using an electrical force that causes objects to attract each other with static electricity. When positive and negative voltages are applied to the internal electrodes of the chuck while the workpiece is placed on the chuck, the electric charges in the workpiece move so that they are attracted to the internal electrodes. This generates a Coulomb force between the electrodes and the workpiece, and the workpiece is adsorbed to the chuck.

Electrostatic chucks can be divided into two types according to the difference of the chucking method: one is the Coulomb force type that uses insulating material as the dielectric. One is the Coulomb force type, which uses an insulating material as the dielectric, and the other is the Johnsen-rahbek force type, which is induced by a small current flowing in a small gap at the interface between the object and the dielectric, resulting in an electrostatic polarization.

Electrostatic chucks are suitable for gripping very delicate workpieces such as metal foils and films because they do not use physical constraints. Therefore, they are used for chucks to transport wafers in semiconductor manufacturing equipment.

Matsusada Precision handles high-voltage power supply equipment for electrostatic chucks. Whether it is an electrostatic chuck using the Coulomb force or the Johnsen-rahbek force, we have the lineup for both.

- Related words:

-

- electrostatic chuck

- Coulomb force

- Johnsen-rahbek

- force wafer transfer

- semiconductor manufacturing equipment

- semiconductor adsorption