Materials such as polymers and plastics used in wire coatings are known as insulators because they block the flow of electric current. A dielectric is a specific type of insulator that, while non-conductive, creates electric polarization when an electric field is applied. This property allows dielectrics to store electrical energy, making them essential components in capacitors, where they are placed between positive and negative electrodes.

Comparison of Dielectrics and Insulators

While dielectrics and insulators both have in common in that they obstruct DC, the dielectrics allow AC to pass since a capacitor element using the dielectric will have resistance (impedance) corresponding to the frequency. In AC circuits, however, dielectrics allow current to pass effectively because the capacitor's impedance decreases as the frequency increases. While they do not conduct current like a metal wire, they facilitate the flow of AC energy through charge displacement. What difference does this make?

Dielectric Polarization and Constant

Dielectric materials are also used in capacitors, but electricity does not directly pass through the dielectric. Therefore, the dielectrics are categorized into insulators. However, the dielectrics have a property of passing high-frequency AC currents with an impedance (resistance).

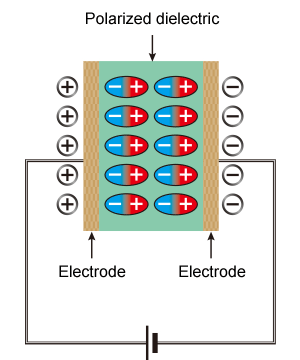

The dielectric material becomes polarized when sandwiched between positive and negative electrodes. Dielectric polarization occurs when an electric field is applied. An alignment of positive and negative charges takes place at the molecular level, resulting in polarization corresponding to positive and negative electricity.

The polarized dielectrics have the property of attracting electrons onto the electrodes. The polarization prevents some of the electricity (electrons) from leaving the electrodes of the capacitor, which enables it to store electrical energy. In AC circuit, as the frequency increases, the positive and negative charges on both poles of the capacitor are frequently switched, and some of the electricity that cannot leave the capacitor electrodes resists the switching, which becomes the impedance.

While dielectrics are categorized into insulators, they can store electricity and provide electrical resistance in AC circuits.

The dielectric constant is the ratio of the applied electric field strength. It is also an indicator of polarizability. The dielectric constant often shows the ratio in vacuum, and it varies depending on the type of dielectrics. Dielectric substances have an impact on the capacitor performance.

| Material | Dielectric constant |

|---|---|

| Barium titanate | approx. 5000 |

| Water | 80.4 (20°C *Varies greatly depending on temperature) |

| Alumina | 8.5 |

| Mica | 7.0 |

| Quartz | 3.8 |

| Glass | 5.4 to 9.9 |

| Rubber | 2.0 to 3.5 |

| Paper | 2.0 to 2.6 |

| Paraffin | 2.1 to 2.5 |

| Air | 1.00059 |

*from Wikipedia (CC BY-SA 3.0)

Electrical Difference Between Conductor, Semiconductor, and Insulators

What is the difference in atomic structure between conductors and insulators? Conductors such as metals that can easily conduct electricity are used in electric wires. When metals are considered at the atomic level, they possess an incomparably greater number of "free electrons" that can move around freely than other materials. These free electrons move when voltage is applied, resulting in the flow of electricity.

What about semiconductors? They do not have as many free electrons as metals, but they do have the property of ejecting free electrons when energy is applied to them from the outside. Depending on materials and manufacturing methods, it is also possible to create semiconductors with many free electrons (n-type semiconductors) and semiconductors with many holes (p-type semiconductors), which are the counterpart of electrons (p-type semiconductors).

By combining these two types of semiconductors, it is possible to create a diode that allows current to flow in only one direction, or a transistor that controls the flow of current only when desired. For a diode, when current is blocked in a particular direction, it acts as an insulator and does not permit current to flow. In other words, a "semiconductor" can behave like a metal (a conductor) or an insulator depending on the conditions.

Insulators have very poor conduction and no free electrons in their atoms. They have very low conductivity and emit free electrons when energy is applied, the same as semiconductors. Still, the energy required to reach this point is so great that electricity cannot easily pass through it. Vinyl, plastics, rubber, etc. are insulator materials. Dielectrics are insulators in a sense which do not easily conduct electricity.

Insulator Breakdown Condition

Insulators play a vital role in electrical safety, but they have physical limitations. If a voltage exceeding the material's dielectric strength is applied, dielectric breakdown occurs. Semiconductors emit free electrons as energy is applied. Due to their atomic-level structure, insulators release free electrons when subjected to energy exceeding a specific voltage threshold.

For example, air is also generally an insulator that does not conduct electricity. But when static electricity in clouds builds up to a high-voltage condition, electricity flows due to the voltage difference with the earth (lightning strike). This natural phenomenon is also an insulator breakdown caused by the energy of a certain voltage being applied to the air. It is also applied to wire sheathing and dielectrics such as vinyl wires when a voltage over the allowable voltage is supplied. Therefore, proper insulation design is critical to prevent breakdown, ensuring that applied voltages remain within the material's safe operating limits.

Electrostatic Charge and Discharge

Static electricity is an imbalance of electrical charges within or on the surface of an insulating material such as plastic or vinyl. It is generated by friction and separation of the materials like plastics with a fleece blanket, etc. The rubbing releases negative charges, called electrons, which can transfer and build upon one object to produce static electricity (a state in which the number of electrons and holes are different and have different voltages.

The materials will become "charged" with static electricity. After they are charged, the free electrons give them the ability to "discharge" when they come close to another conductor with a different potential. Some substances are negatively charged (easily receive electrons) and others are positively charged (easily emit electrons). When a finger or metal touches a charged substance, it emits electrons or inflows electrons and returns to a stable state.

The electrostatic discharge or ESD also may be responsible for damaging electronic components such as ICs and capacitors when static electricity can reach voltages as high as several kV, unlike standard electronic circuits. Therefore, the prevention of ESD is necessary to reduce the generation of static electricity or add circuits to protect electronic components from static discharge.

Dielectric in Capacitor

A capacitor consists of dielectric sandwiched between electrodes. Varied capacitors are used depending on the dielectric materials as follows.

Film capacitor

Film capacitors typically use plastic films, such as polyethylene or polypropylene, between electrodes to ensure electrical isolation. While it has not only a long life but is inexpensive, the film capacitor has a dielectric constant of approximately 3 with lower capacitance than others. We can see the film capacitor used for noise reduction in audio equipment.

Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are constructed by sandwiching electrolytic paper between electrodes made of aluminum foil.

The aluminum oxide formed on the surface of the aluminum foil serves as the dielectric. With a relatively high dielectric constant of approximately 8, these capacitors can achieve high capacitance. However, since the electrolytic paper is filled with electrolyte, current may leak between the electrodes, preventing complete electrical isolation. Furthermore, the electrolyte is a consumable material that gradually evaporates, meaning the capacitors periodically require replacement. Leveraging their high capacitance, these capacitors are widely used in power electronics applications such as power inverters and solar inverters (or power conditioners).

Advancing Ceramic Capacitors

In recent years, some capacitors use new ceramic materials as dielectrics. There have been ceramic capacitors using ceramic as the dielectrics. The dielectric constant of typical ceramic capacitors with limited applications was almost as good as that of film capacitors.

Modern barium titanate ceramics feature a high dielectric constant of approximately 4500, which significantly exceeds that of typical dielectric materials. This exceptional property enables the creation of high-capacity ceramic capacitors. There is currently underway on the use of barium titanate for batteries taking advantage of the capacitor's electricity-hoarding properties.

Electric Insulation materials for Ultra-High Voltage Transmission

For ultra-high voltage operation, reliable high-voltage insulation is essential. Ceramic insulators are widely used in high-voltage applications due to their high mechanical strength and excellent insulating properties. These insulating components, often made of porcelain (a type of ceramic), are used in applications like transmission towers and train pantographs. For many years, insulators have been utilized to support and insulate transmission towers standing on the ground from power lines, owing to their exceptionally high mechanical tensile strength and insulating capability (or dielectric strength).

Rubber materials are also used for high-voltage isolation.

Such rubber materials, referred to as insulating materials, must have high insulation resistance and dielectric strength without isolation breakdown.

Dielectric breakdown tests are conducted to measure the dielectric strength as the voltage is used to ensure reliability. In the dielectric breakdown testing, a high voltage is applied to the insulating material, and the voltage at which it is destroyed is measured. If the material can withstand high voltage for a specified period, it is judged to have sufficient insulating strength at the test voltage.

High dielectric strength for high voltage applications makes the product safe and high quality, leading to longer service life.

Insulation Materials -- Quick Reference

This table lists representative dielectric constants and dielectric strengths of common insulation materials.

The materials are arranged in order of dielectric strength (kV/mm) from lower to higher values. Please note that the values shown are representative and can vary significantly depending on conditions such as temperature, humidity, pressure, electrode geometry, and impurities.

| Material | Form | Dielectric Constant (εr) | Dielectric Strength (kV/mm) | Features/Typical Applications |

|---|---|---|---|---|

| CO2 | Gas | 1.0 | 2.5-3 | Low-cost alternative to SF6. Lower insulating strength. |

| Air (dry) | Gas | 1.0 | ~3 | Standard insulating medium. Reference for dielectric tests and air gaps. |

| Nitrogen (N2) | Gas | 1.0 | 3-4 | More stable than air. Filling gas for HV equipment. |

| Water (very pure) | Liquid | ~80 | 5-10 (very pure)/<1 (tap water) | Very high dielectric constant when pure, but conductivity rises rapidly with impurities. Used in some capacitors and cooling systems. |

| SF6 (Sulfur hexafluoride) | Gas | 1.0 | 8-10 | Very high insulating strength. Widely used in GIS and some X-ray systems. Strong greenhouse gas and regulated. |

| Paper (impregnated) | Sheet | 3.5-4 | 8-15 | Used in transformers and capacitors. Oil impregnation increases dielectric strength. |

| Mineral Insulating Oil | Liquid | 2.2-2.3 | 10-15 | Transformer oil -- provides insulation and cooling. |

| Ester Oil (synthetic / natural) | Liquid | 3.0-3.2 | 10-15 | Eco-friendly alternative to mineral oil. Used in transformers. |

| Quartz (SiO2) | Solid (crystal / glass) | 3.8-4.2 | 10-15 | Excellent thermal stability and low loss at RF/microwave. Used in oscillators and optics. |

| Alumina (Al2O3) | Ceramic | ~9-10 | 10-20 | High mechanical strength and thermal conductivity. Used for HV substrates and insulators. |

| Ceramics (general: Al2O3, TiO2, etc.) | Solid | 6-10 | 10-20 | Wide range of dielectric properties. Used in HV insulators and capacitors. |

| Glass | Solid | 5-7 | 10-30 | High chemical resistance. Used in vacuum seals, windows, and X-ray tubes. |

| Epoxy Resin | Casting/potting | 3.6-4.2 | 15-25 | Sealing and impregnation. Moisture resistant; commonly used for potting HV components. |

| Glass Epoxy (FR-4) | Laminate | 4.2-4.8 | 15-20 | Standard PCB substrate. Good mechanical strength and machinability. |

| Acrylic (PMMA) | Sheet | 2.6-3.2 | 15-25 | Transparent and easy to process. Used for insulating plates and display windows. |

| Rubber (Natural/EPDM) | Elastomer | 2.5-3.5 | 15-30 | Flexible; used for cable jackets, boots, and gaskets. |

| Silicone Resin (rubber) | Elastomer | 2.8-3.2 | 20-25 | Flexible, heat-/weather-resistant. Used for HV cable insulation and outdoor insulators. |

| Silicone Oil | Liquid | 2.7-2.9 | 15-20 | High thermal resistance. Used in HV supplies and X-ray equipment. |

| Paraffin Wax | Solid (wax) | 2.1-2.4 | 20-30 | Low-cost dielectric; used historically for capacitor dielectrics, potting and insulation fillers. |

| PTFE (Teflon®) | Film / insulator | 2.1 | 60-100 | Very low dielectric loss and excellent chemical resistance. Used in RF circuits and HV cables. |

| Mica | Sheet | 6-7 | 100-200 | Excellent dielectric strength and heat resistance. Used in HV capacitors and motor insulation. |

| Polyester (PET, Mylar®) | Film | 3.2 | 150-200 | Economical film for capacitors and slot liners. |

| Polyimide (PI, Kapton®) | Film | 3.4 | 200-300 | High thermal endurance and dielectric strength. Used in motor windings and flex PCBs. |

| Barium Titanate (BaTiO3) | Ceramic (ferroelectric) | ~1000-5000 | 10-15 | Extremely high permittivity; used in MLCCs and ferroelectric devices. Bulk dielectric strength similar to ceramics. |

| Vacuum (below 10-3 Pa) | Alternative to gas | ≈1.0 | ~20 (effective) | Very high insulation if pressure is sufficiently low. Used in X-ray tubes and vacuum interrupters. Note: surface flashover depends on electrode geometry. |

Related Columns

Recommended products

Matsusada Precision's programmable DC power stations are available in electronic material testing of dielectrics and insulators and dielectric breakdown testing (Hipot testing). We provide a broad lineup of high voltage power supplies ideal for testing and evaluating capacitors and batteries, production line and piezo driver applications.