High Voltage Power Supply Applications: The Process

What is Electrophotography (Xerography)?

Electrophotography, also known as xerography, is a printing technology widely used in devices such as laser printers, copiers, and fax machines. This technology, central to everyday printing equipment, utilizes electrostatic forces to transfer toner (a fine powder) onto paper, thereby forming an image.

Achieving this precision process requires highly accurate voltage control at each step. Our high voltage power supplies and high voltage amplifiers play a crucial role in the development and manufacturing of these systems.

The Basic Electrophotographic Process and the Role of High Voltage Power Supplies

The electrophotographic process mainly consists of the following steps: charging, exposure, developing, transfer, fusing, and cleaning. Let's explore how high-voltage technology is utilized in each of these stages.

1. Charging

Charging the photoconductor drum is the first step in the printing process. The entire surface of a drum, coated with a photoconductive material whose electrical resistance decreases when exposed to light, is uniformly charged. There are two primary methods for this step:

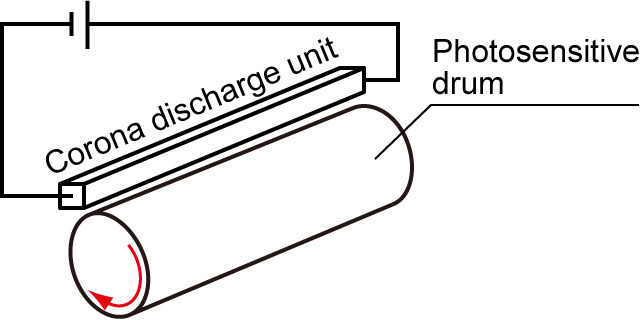

Corona Charging

This non-contact method involves applying a high voltage to a wire to generate a corona discharge, using the resulting ions to charge the drum's surface. A Corona Generator is used to create this discharge. To achieve a more uniform charge, devices called scorotrons, which feature an additional grid electrode, are also utilized. A stable high voltage power supply is essential for these devices.

Contact Charging

In this method, a conductive roller known as a Primary Charge Roller (PCR) is brought into direct contact with the drum, and a high voltage is applied to charge it. A key advantage of this method over corona charging is the reduced ozone generation. Precision high voltage DC power supplies or AC power supplies are used for the PCR.

2. Exposure

The charged photoconductor drum is exposed to light in the pattern of the image or text to be printed. In the areas struck by light, the electrical charge dissipates, creating an invisible electrostatic latent image on the drum's surface.

In a laser printer, a laser beam is reflected by a rapidly rotating polygon mirror to scan across the drum, drawing the latent image.

In an LED printer, a linear array of LEDs (Light Emitting Diodes) is used instead of a laser, creating the latent image with a simpler mechanism.

3. Developing

Charged toner is brought near the surface of the drum where the latent image has been formed. Due to the potential difference between the latent image (the exposed areas) and the rest of the drum, the toner selectively adheres only to the latent image. This makes the image visible.

A bias voltage is applied to the Developer Roller to control the toner adhesion. To achieve sharp, high-quality prints, this bias voltage must be controlled with extreme precision, requiring a low-noise, highly stable high voltage power supply.

4. Transfer & Fusing

Transfer: Paper is pressed against the drum, and a high voltage of the opposite polarity to the toner is applied to the back of the paper. This attracts the toner from the drum onto the paper.

Fusing: The paper, now carrying the toner image, passes through a fuser unit composed of heated pressure rollers. This process melts the toner, permanently bonding it to the paper fibers.

Matsusada Precision's Solutions

Matsusada Precision offers optimal solutions with our high voltage power supplies and high voltage amplifiers for the development, evaluation, and manufacturing of every stage in the electrophotographic process, especially where precise voltage control is critical, such as in power supplies for corona chargers, Primary Charge Rollers (PCR), and Developer Rollers.

Our COR series precisely controls the current of the corona discharge, enabling a well-balanced charge on the photoconductor drum. Furthermore, our extensive lineup of high voltage amplifiers and modular power supplies contributes to enhancing the performance and quality of electrophotographic technology, tailored to meet customer-specific requirements.

Our products, embodying the quality and reliability of Japanese manufacturing, are compact, high-performance, and feature a sophisticated design, earning high praise from engineers and researchers worldwide.

- Related Terms:

-

- Corona generator

- Corona charging

- Corona discharging

- Corotron

- Developer roller

- Paper charge

- Photoconductor

- Primary Charge Roller (PCR)

- Scorotron grid supply