Piezo drivers are high-voltage amplifier-type power supplies designed to stably control the displacement or vibration of piezo elements according to their specific application. Piezo elements have the characteristics of capacitive elements.

To drive them optimally, a power supply capable of both sourcing (charging) and sinking (discharging) current is required, unlike a standard programmable DC power supply. In addition, driving at high speeds requires not only fast responsiveness but also higher output current. The first step in selecting a piezo driver is to choose a power supply that matches both the piezo element and the operating conditions (waveform, frequency, load). When driving an actuator with pulses, ringing often appears in the output waveform, and abnormal oscillations can sometimes occur. This can lead to degradation or breakage of the piezo element. Our designs have taken this into consideration. The Matsusada Precision piezo driver is a versatile product that supports a variety of piezo elements, including those with a wide range of capacities, and provides stable operation. This power supply enables optimal driving to achieve the full performance of piezo elements.

Piezo Application Examples

Applications include X-Y stage and lens/mirror positioning, optical fiber fusion bond positioning, inkjet printer and electronic valve control, part feeder vibration, ultrasonic wave generation, and precise positioning for analyzers.

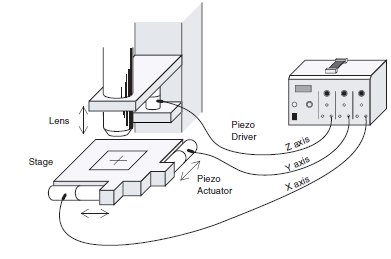

Driving microscope lenses and stages

The figure on the left is a simplified representation of using a piezo driver to focus and operate the lens of a microscope and to position the sample stage. A 3-channel output model allows positioning along the X, Y, and Z axes to be performed with a single unit.

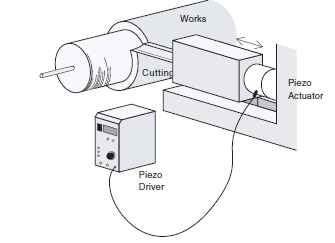

Positioning for detailed machining

The figure on the left is a simplified representation of using a piezo driver for the machining of metal.

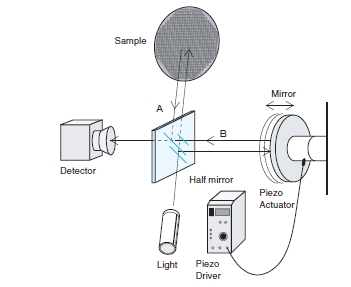

Fine adjustment of optical measuring devices

The figure on the left shows a Michelson interferometer, which measures the accuracy of the surfaces of light source lenses and mirrors.

Each time the sample changes, images A and B are re-aligned in units of µm. A piezo actuator is used to make fine adjustments to this mirror.

Relationship Between Response Speed and Output Current

- When choosing a piezo driver, several key specifications must be considered. The required output voltage range (or peak-to-peak voltage) needed to achieve the desired displacement, the load capacitances of the piezo elements being driven, and the driving waveform and frequency determine the necessary output current of the driver.

Check the individual specifications for each piezo driver to choose a model that satisfies these performance conditions.

- The following formula is used to find the output current.

- For sine wave drive:

- To find the operating frequency at which each driver can be driven, the formula above is changed to f = Imean/2.2 C Vp-p

-

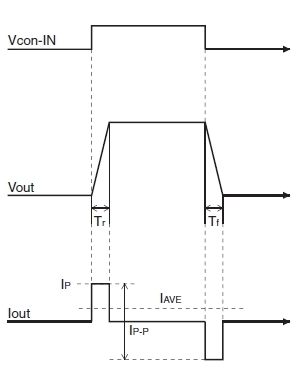

For pulse drive:

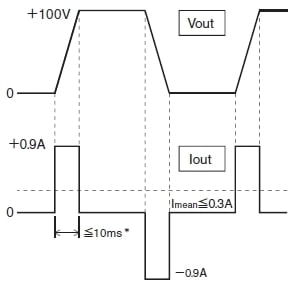

- (Note that this peak current, IP, can only be sustained for a short duration, typically 10 ms or less. Refer to the specifications for each driver.)

- To find the rise time for each driver, the formula is rearranged to Tr = (Vp-p * C) / IP. (The same applies to Tf.)

However, since it is limited by the value of the output resistance, set the rise time to either the above formula or 3τ = 3RC, whichever is the slowest.

- Imean: Rated output current ... (A)

- IP: Peak output current ... (A)

- Vp-p: Output voltage peak-to-peak ... (V)

- R: Output resistance ... (Ω)

- C: Piezoelectric capacitance ... (F)

- Tr: Rise time ... (S)

- Tf: Fall time ... (S)

- 3τ: Approx. 90% arrival time ... (S)

Function for Increasing Peak Power

This function is supported for all of our piezo drivers. An output peak current that is approximately 3 times the rated current is possible. For applications with a low repetition frequency and low average power (such as positioning), this function enables high-speed startup even with a compact driver. For example, even though PZJ-0.1Px3 is rated at 300 mA, a peak current of 900 mA is possible. If the average output current is 300 mA or less, it can be operated as a ±900 mA power supply. (See the figure below.) With this model, an output of 100 V allows a 1-µF piezo element to start up in 0.11 ms. For pulse drive applications, operation up to 1.5 kHz is possible on each of the 3 channels.

* Pulse width of current is within 10 ms.

Bias Function

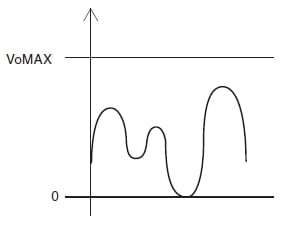

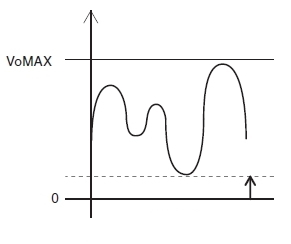

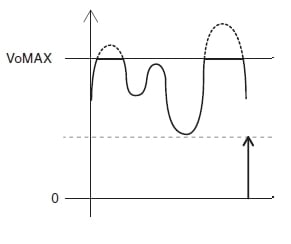

The bias function is an extremely convenient feature that allows a DC offset to be superimposed on the output voltage. By using the dial on the front panel to set the bias, you can move the output waveform freely within the rated output range. (See Figures (a) and (b) below.) If the resulting waveform (signal plus bias) exceeds the rated output range, the output will be clipped. (See Figure (c) below.)

By using the bias function, it is possible to directly change the displacement reference position of the piezo element without changing the control voltage, which is effective for position adjustment and DC operation.

Also, by setting the control signal to 0 V, you can use only the bias function to use the product as a constant voltage DC power supply. Although PZM series, PZM-B(0.3) series, and PZM-B series have no bias function, you can apply bias by adding a DC offset to the external control signal.

Fig. 3 Explanation of Bias Function

Related Technical Articles

- Application: Piezo Driver

- Amplifier Basics: Principles, Operation, and Key Considerations

- Safety and Usage of High Voltage Power Supply

- What are Piezoelectric Devices? Principles, Structure, and Applications Explained

- Application: Piezoelectric device (Piezo Device)

- Proper Usage Guidelines for Piezoelectric Actuators

- What is a Piezo Actuator? (Basic Knowledge)

Recommended products

Matsusada Precision provides precision control solutions with piezo actuators and piezo drivers.