I need the power supply to perform the same action repeatedly.

I need to keep a record of the operation.

I need to run a lot of power supplies at the same time.

I need to link the operation of the power supply with other devices.

I need to change the power supply's output voltage little by little.

In such cases, it is impossible to control the power supply directly from the power supply's front panel.

This is where "digital remote control" becomes necessary.

The remote control is a method of controlling a power supply or other device by connecting it to a computer or programmable logic controller (PLC) via a communication cable.

However, for remote control, you must prepare control software on the computer side.

Programming is required to create control software, but it is a difficult task that requires specialized knowledge.

Therefore, in this guide, we provide an easy-to-understand overview of remote control, programming languages, and drivers to make the process as simple and accessible as possible.

Communication port

When controlling devices such as power supplies from a computer, it is necessary to prepare communication cables that match the respective communication ports.

The communication ports include the following.

Choose the one that best suits your needs, including the number of connections, communication speed, communication distance, and ease of connection.

If the power supply itself does not have a digital communication port, it must be connected via a dedicated adapter.

Please refer to the datasheet of the power supply and the datasheet of the digital controller.

- General communication ports

- LAN

- USB

- GPIB (IEEE 488.2)

- RS-232C

- RS-485

Control software

To prepare the control software, you can either program it yourself or obtain the control software designed by the equipment manufacturer.

We also have sequence control software PSS2 for power supplies and electronic loads and CD-BC for charge/discharge power supplies. These software packages allow for sequence control, multi-unit management, and operation logging. (For details, please refer to the respective datasheets.)

In addition, if you want to control measuring instruments or relays, or perform complex sequence control, you will need to program the control software yourself.

Programming language

To create control software, you will need a programming language.

(There have been many programming languages developed in the past and present.)

The programming language should be one that runs on the operating system of the computer to be used.

In addition, in programming, selecting a driver and sample program that matches the programming language is a shortcut to completing the control software.

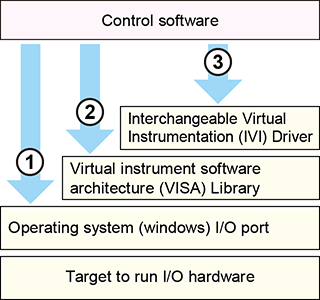

Structure of the control software

When creating software for control, you need to know the structure of the software. In general, this is how it works.

The control methods can be roughly divided into three categories.

- Direct access and control of operating system I/O

- Access and control via the VISA library

- Access and control using an IVI driver

Each method has its own advantages and disadvantages.

Recently, there has been an increase in control using standard definitions such as SCPI command, one of the commands used in the VISA library in No.2, and IVI driver in No.3.

The use of standard definitions for programming control software has the following advantages

- Since programming is independent of device manufacturers, portability and versatility are increased.

- You can program without worrying too much about the different ports.

- Different types of devices, such as power supplies and measuring instruments, can be programmed on the same platform.

IVI Driver

This section describes the IVI driver mentioned in the "Structure of control software" section above.

- The IVI standard defines "instrument classes".

This allows instruments of the same class to be used with the same command.

It also defines common functionality that does not depend on classes, and a programming environment with commonality is a great advantage. - The IVI driver supports many programming languages.

The driver is compatible with a wide range of development environments, supporting the following programming languages.

Matsusada Precision offers IVI driver support for several DC power supply models, including the REK and REKJ series.

Programming languages and software supported by the IVI driver

- LabVIEW

- Visual Basic

- Visual C#

- Visual C++

- Visual Basic .net

- Excel VBA

- MATLAB

- Lab Windows

- Measure Foundry

- VEE

- Delphi

etc...

Support for programming

So far, we have provided preliminary instructions for creating software for remote control.

The next step is to create the software for remote control, and this is where sample software, tutorials, and programming guides come in handy.

We have also included sample programs in the instruction manuals of our power supply devices to help you get started with programming smoothly.

In addition, programming guides for LMi Visual Basic, Visual C#, and Visual C++ are available.

To the glossary of remote control programs

GlossaryRelated Technical Articles

Recommended Products

The following products support programming with IVI drivers.