Ion milling is a processing device that radiates an argon ion beam on the surface of a sample to be observed to polish and etch the surface.

Mechanical polishing on materials such as copper and aluminum tends to be crushing and heat sagging. With ceramics and silicon, cracks are more likely to occur while polishing. Thin films are also difficult to machine polish with conventional methods. Meanwhile, processing with an ion milling device is designed to prepare samples according to purposes, and you can use appropriate materials for the observation.

Furthermore, while chemical etching has been required to observe crystals in metallic materials, ion milling reduces man-hours by using an argon ion milling device with ion beam etching. Especially for ion milling systems with fine precision, the processing is performed using a Focused Ion Beam (FIB) processing observation device employing a Scanning Electron Microscope (SEM). FIB uses a gallium ion beam.

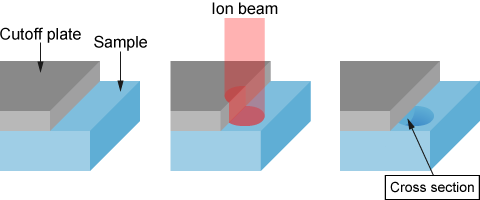

Ion milling is divided into cross-section milling and flat milling. Cross-section milling is suitable for cross-sectional observation of each layer's thickness, layer structure, and surface finish because it can generate cross-sections without applying external stress. Flat milling is used for final finishing after machine polishing, etc. because it can produce surfaces with reduced unevenness formation by adopting the ion beam radiation at approximately a 90-degree angle.

The acceleration voltage of the beam in ion milling is typically 1 kV to 8 kV. Matsusada Precision's compact high-voltage power supplies output 1kV to 10kV for ion milling.

- Related words:

Recommended products

Matsusada Precision's compact high-voltage power supplies output 1kV to 10kV for ion milling.