Some test equipment requires boosting the voltage of commercial 100 VAC to generate high voltage. In electric vehicles, the voltage of inverters and battery circuits is increasing with the increasing voltage of motors. Familiar high-voltage equipment includes X-ray machines (X-ray diagnostic imaging equipment). X-ray tubes used in medical X-ray machines and analyzers are vacuum tubes that must be replaced after a certain amount of operating time. The X-ray tube and high-voltage power supply are connected via high-voltage connectors to ensure easy interchangeability. Thus, high-voltage connectors are commonly used to connect high-voltage devices used in medical, scientific, and analytical equipment to improve their ease of use and reduce maintenance.

This section describes the types of high-voltage connectors, which are safe and reliable for use in high-voltage circuits, and precautions for their use.

Characteristics of high-voltage connectors

High-voltage connectors allow easy installation/uninstallation of high-voltage wiring, eliminating the need for screw fastening employed in normal wiring connections. Thus, high-voltage devices (e.g., X-ray tubes, PMTs, piezo, MCPs, electron beams, and ion beams) can be easily changed or replaced, and equipment can be easily moved or relocated. Wiring connections can be made quickly and easily by using high-voltage connectors for changing and moving around equipment in laboratories, facilities, and factory production lines.

Types of high-voltage connectors and their overview

There are many types of high-voltage connectors and applications for high voltages, including the transmission of electrical power and use of high voltages in medical and scientific applications. High-voltage connectors are used for easy connection and disconnection when installing wiring to send high-voltage electricity from a power source to a device. They can be classified into three main types depending on the type of high-voltage cable used.

- • Non-shielded high-voltage cable connectors

-

These include high-voltage connectors used for single-core high-voltage cables without a shield, high-voltage silicon cables, and high-voltage Teflon cables. There is no general standard, and instead specialized connectors unique to high-voltage devices and connector makers are used.

- • Coaxial high-voltage cable connectors

-

High-voltage connectors such as BNC, MHV, or SHV are used for connecting shielded single-core coaxial cables. Although other connectors for coaxial cables, such as SMA, SMB, and SMC, can be used, they cannot be used for very high-voltage applications. There are also proprietary high-voltage connectors of connector manufacturers that are used as de facto standards in certain applications.

- • Multicore high-voltage cable connectors

-

Multicore high-voltage cable connectors are used for X-ray tubes, electron beams, ion beams, etc. For medical X-ray equipment, connectors are standardized by JIS or other similar standards.

Common types of high-voltage connectors include

Miniature High Voltage (MHV)

MHV, also called BNC-HV (BNC high-voltage), is a high-voltage connector used to connect high-voltage coaxial cables to various devices.

When transmitting high-frequency power, electricity cannot be transmitted successfully if coaxial cables and connectors with different characteristic impedances are connected. Therefore, coaxial cables and connectors with matching impedances must be properly connected.

Although MHV connectors appear similar to BNC connectors, they can be used at higher voltages than BNC connectors. Although MHV and BNC connectors look similar, they are not intermateable due to differences in their insulator projections. (Some offices prohibit the use of MHV connectors because they can be forcefully connected.)

Safe High Voltage (SHV)

SHV connectors are high-voltage connectors for coaxial cables that can be used at higher voltages than MHV connectors. The plug of the SHV connector is designed such that the insulation surrounding the center of the coaxial section protrudes beyond the center electrode, thereby increasing the creepage distance between the center contact and the outer conductor shield.

Therefore, they cannot be connected to MHV or BNC connectors.

Summary of high-voltage connectors for coaxial cables

High-voltage connectors for coaxial cables include BNC, MHV, and SHV connectors, as well as HN connectors and manufacturer-specific connectors. The specifications of these connectors are summarized below. Please verify the required specifications prior to use as they may differ among different manufacturers. Coaxial cable high-voltage connectors are used in probe-type survey meters (radiation detectors), for example, to connect the probe to the main unit with a coaxial cable.

| Type | BNC | MHV | SHV | HN |

|---|---|---|---|---|

| Rated voltage * | 500 Vrms | 1600 Vrms | 3500 Vrms | 1500 Vrms |

| Impedance | 50 Ω | 50 Ω | 50 Ω | 50 Ω |

| Frequency | DC to 4 GHz | DC to 300 MHz | DC to 300 MHz | DC to 4 GHz |

| Bayonet | Bayonet | Bayonet | Threaded | |

| Standard | JIS-C-5412, MIL-C-3608, MIL-C-39012 |

MIL-C-39012 | MIL-C-39012 | MIL-C-3643 |

|

|

|

|

Precautions for use

The shape of the MHV connector is very similar to that of the BNC connector. Care must be taken not to interchange them.

* The rated voltage is the standard.

High-voltage versions MHV and SHV are available from connector manufacturers.

At Matsusada Precision, MHV and SHV connectors with higher voltage ratings are used for products that output higher voltages than the specified rated voltage.

When using MHV or SHV connectors and cables from other manufacturers, please pay attention to specifications such as operating voltage.

We supply cables with MHV connectors and SHV connectors.

Standards for high-voltage connectors used in X-ray equipment

Although most high-voltage connectors are sold based on the original designs of the manufacturers, high-voltage connectors for X-ray generators used in medical radiography are standardized by JIS Z4731 or other similar standards.

There are two types of contacts, 3-contact, and 4-contact, connected through their respective plugs and receptacles. They are not interchangeable. In the case of 3-contact, each terminal is determined as C (common), L (filament for large focus), and S (filament for small focus). A G (grid electrode) is added in the 4-contact type. Connectors for medical X-ray equipment comprise straight plugs with protrusions to prevent incorrect insertion.

A similar connector called the Federal Standard is used globally.

High-voltage connectors called R24, R10, and R30 with conical high-voltage plugs are used in scientific X-ray analyzers. The plug has three concentric electrodes at the tip and no orientation. R10 is used for voltages up to 100 kV, R24 for up to 160 kV, and R30 for up to 210 kV.

Precautions for maintenance and use of high-voltage connectors

The major difference between using low- and high-voltage electricity is that one must be more careful about safety when using high-voltage electricity. The dangers of commercial 100 V lines are incomparable to those of high-voltage electricity. Therefore, it is imperative to carefully check whether the electrodes are exposed. Depending on the high-voltage connector, if it is not plugged in carefully, the pins may bend and the terminals may contact each other, causing a short circuit or even disconnection. Therefore, it is necessary to thoroughly check the connector terminals for bends or deformations during routine maintenance and prior to connection.

Even if the standards are different, some connectors can be connected via forced insertion. This situation tends to occur when the shapes of the connectors are similar. Additionally, wiring mistakes can occur if there are multiple connectors. In this case as well, a short circuit or miswiring of the high-voltage circuit could cause a failure that could result in complete destruction of the equipment.

Moreover, when the surfaces of the plug and receptacle become dirty, creepage discharge may occur owing to their high-voltage characteristics. Therefore, connectors should be periodically cleaned to prevent insulation failure. Grease is generally used in R24 type connectors; hence, they must be greased periodically.

Other problems include sharp metal debris on high-voltage cables and connectors, which can create holes in the insulating material and cause short circuits. If there is a flammable object in the vicinity, a fire may ensue. High voltages can efficiently transmit a significant amount of energy, but a misconnection or short circuit can have severe consequences; therefore, appropriate measures must be taken to prevent such mishaps.

Demand for high-voltage connectors in BEVs is expected to increase.

When the same amount of power is used, a higher voltage will reduce the current. If the current is low, the size of conductors used in the circuit can be reduced, which results in weight savings and the suppression of heat generation. However, high voltage, instead of low current, increases the risk of arcing between closely spaced conductors just by the proximity of the positive and negative wires. When using high-voltage electricity, maintaining an appropriate wiring distance is an important design factor. There will be cases wherein the wiring will not function the same way as low-voltage wiring. Along with understanding the dangers of high voltages, it is necessary to try to take advantage of their benefits because they can transmit an enormous amount of power with little current.

To distinguish between conventional 12 V and 24 V lead-acid battery wiring in hybrid vehicles and BEVs, the high-voltage circuits are composed of orange cables for easy identification. Orange cables are used for wiring lithium-ion batteries, motors, inverters, and onboard chargers.

As the world moves toward a carbon-free society, electric vehicles (EVs) are expected to become more widespread globally. Battery charging times for EVs can be reduced if the charger can supply more power. High-voltage circuits can be used to reduce the charging current, thereby reducing the number of materials used in chargers and electric vehicles. Therefore, the demand for high-voltage connectors for charging EVs is expected to increase considerably in the future. Although high-voltage coaxial cables are currently not used for recharging EVs, we expect that in the future they will be used in applications that have not yet been envisioned, such as information transmission while recharging.

Manufacturers of high-voltage connectors

There are many manufacturers of various types of high-voltage connectors that market their products. The following are the major manufacturers of high-voltage connectors.

Matsusada Precision

We manufacture high-voltage connectors that are unique to manufacturers of high-voltage power supplies. Safe and reliable connectors are standardized for each voltage.

Please visit this page to check the high-voltage connectors and cables offered by Matsusada Precision.

To-Conne Co., Ltd. (https://www.to-conne.co.jp/)

To-Conne is a Japanese manufacturer of connectors, such as MHV and SHV, and harnesses for coaxial cables.

TAJIMI ELECTRONICS CO., LTD. (https://ssl.tajimi.co.jp/)

Tajimi Electronics is a specialized manufacturer of connectors for coaxial and optical cables, and they also fabricate connectors for high-voltage coaxial cables.

LEMO (https://www.lemo.com)

LEMO is a Swiss connector manufacturer. They specialize in manufacturing circular connectors and employ a unique push-pull self-latching system that enables easy one-touch mating and release. We at Matsusada Precision also use this system in some of our piezo drivers.

Amphenol Corporation (https://www.amphenol.com/products/connectors)

Amphenol is an American manufacturer based in Connecticut that specializes in connectors.

They manufacture a wide variety of connectors for aerospace equipment, telecommunications equipment, and electric vehicles.

Dielectric Sciences, Inc. (https://www.dielectricsciences.com/)

Dielectric Sciences is an American manufacturer of high-voltage connectors based in Massachusetts.

They also manufacture high-voltage connectors for X-ray equipment.

GES High Voltage, Inc. (https://www.ges-highvoltage.com/)

GES is a German manufacturer that specializes in high-voltage connectors. They produce a variety of single and multi-pin high-voltage connectors for industrial applications such as semiconductor manufacturing equipment and cyclotrons; their products can handle up to 100 KV DC.

Yazaki Corporation (https://connector.yazaki-group.com/english/index.html)

Yazaki Corporation produces and sells high-voltage connectors that are primarily used in high-voltage circuits of automobiles.

Recommended products

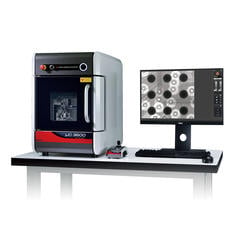

Matsusada Precision offers a wide range of products for X-ray non-destructive testing that can be used for identifying faults such as cable breaks and connector contacts.