Ion milling is a sample preparation technique that uses a broad beam of argon ions to polish or etch a sample's surface for subsequent observation and analysis.

Mechanical polishing of soft materials, such as copper and aluminum, often introduces artifacts like smearing and thermal deformation. With ceramics and silicon, cracks are more likely to occur while polishing. Thin films are also difficult to machine polish with conventional methods. Meanwhile, processing with an ion milling device is designed to prepare samples according to purposes, and you can use appropriate materials for the observation.

Furthermore, while chemical etching has been required to observe crystals in metallic materials, ion milling reduces man-hours by using an argon ion milling device with ion beam etching. For highly precise, site-specific milling, a Focused Ion Beam (FIB) system is often used. Unlike broad-beam argon milling, FIB utilizes a finely focused gallium ion beam. These systems are frequently integrated with a Scanning Electron Microscope (SEM) in a dual-beam configuration (FIB-SEM) to allow for simultaneous processing and high-resolution imaging. FIB uses a gallium ion beam.

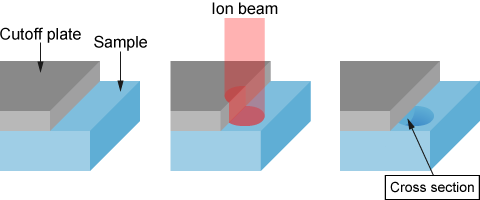

Ion milling is divided into cross-section milling and flat milling. Cross-section milling is suitable for cross-sectional observation of each layer's thickness, layer structure, and surface finish because it can generate cross-sections without applying external stress. Flat milling is used for final finishing to create a large, smooth, and artifact-free surface. This is achieved by directing the ion beam at a very low, or grazing, angle relative to the sample surface, which preferentially removes asperities and reduces topography.

The acceleration voltage of the beam in ion milling is typically 1 kV to 8 kV. Matsusada Precision offers a range of compact high-voltage power supplies that provide stable output voltages from 1 kV to 10 kV, making them ideal for ion milling applications.

- Related Terms:

Recommended products

Matsusada Precision offers a range of compact high-voltage power supplies that provide stable output voltages from 1 kV to 10 kV, making them ideal for ion milling applications.