Dielectric withstand testing is essential for ensuring product safety. It validates insulation integrity to prevent electric shock and current leakage during operation. This testing verifies the performance of insulating materials used in components such as power cables, wire harnesses, and signal cables for high-voltage generators and electronic systems.

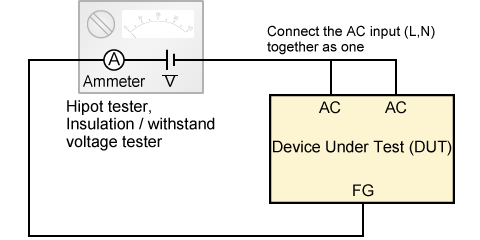

Insulation testing primarily consists of two methods: insulation resistance testing and dielectric withstand testing (also known as hipot testing). Insulation resistance testing applies a specific DC voltage to measure resistance and detect leakage current. In contrast, dielectric withstand testing applies a significantly higher voltage for a short duration to ensure the insulation does not break down under stress. Test parameters and required values are strictly defined by applicable safety standards for each product category.

Reliable testing requires precise high-voltage generation. Matsusada Precision offers a comprehensive lineup of high-voltage power supplies engineered for rigorous dielectric withstand and insulation resistance testing applications.

- Related Terms:

-

- Film

- Plastic

- CV Cable

- Wire Harness

- Signal Cable

- High Voltage

- Insulation

- Transformers

- Generators

- Insulation Material

- Safety

- Insulation Resistance

- Dielectric Breakdown test

- Insulation breakdown test

- Hipot testing

Recommended products

Power supply equipment for insulation testing is available.