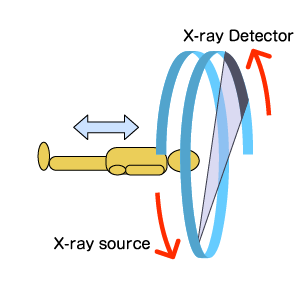

The primary difference lies in the scanning configuration and the inspection purpose. Medical CT scanners rotate the X-ray source and detector around the patient to prioritize scanning speed and minimize radiation exposure.

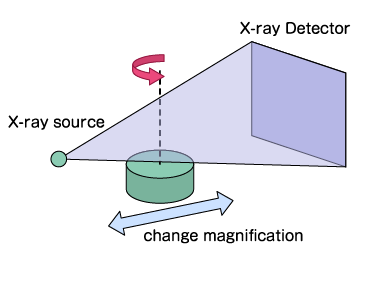

In contrast, industrial CT scanners typically rotate the sample on a precision stage while the source and detector remain stationary. This stable configuration allows for higher magnification and resolution, which are essential for the non-destructive testing (NDT) of electronic components and industrial parts.

Related Articles

- Basics and Principles of Computed Tomography (CT)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- Micro-CT Scanners Complete Guide: Types, Sample Images & More

- What are X-rays? (Basic Knowledge)

- Safe Operation of X-ray Inspection Systems

- Understanding Radiation: Effects on the Body and X-ray Safety

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?