For an overview of general surface finishing technologies, please refer to our technical article:

"An Introduction to Surface Treatment and the Role of Power Supplies"

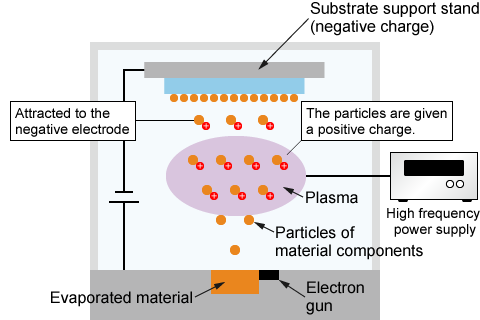

What is Ion Plating?

Ion plating is a specialized Physical Vapor Deposition (PVD) technique used in aerospace, automotive, and precision industrial applications. Unlike traditional wet plating, this "dry" process is conducted in a vacuum environment, ensuring high purity and control.

Process Overview

In the vacuum chamber, the coating material is evaporated or sublimated and passed through a plasma field. This ionizes the particles, giving them a positive charge. The substrate is held at a high negative potential using a specialized DC or pulsed DC power supply. This negative bias accelerates the ionized particles toward the substrate with high kinetic energy.

Key Benefits

- Superior Adhesion: The high-energy impact of ions creates a strong bond between the film and the substrate.

- High Film Density: The accelerated deposition results in a dense, uniform coating.

- Enhanced Durability: Ideal for creating coatings with high hardness and wear resistance.