Ultrafine fibers are defined as fibers finer than silk and are also called nanofibers. In addition to conventional thermoplastic polymers, ceramic nanofibers such as alumina, zirconium oxide, and titanium oxide are also being produced. Nanofibers are used in a wide range of fields such as filters, high-performance masks, protective clothing, and regenerative medicine.

One of the methods of nanofiber production is electrospinning. Electrospinning can be used to spin various materials such as polymers into nanofibers. Electrospinning can produce ultra-fine fibers with diameters of 50 to 500 nm, and is characterized by its easy operation.

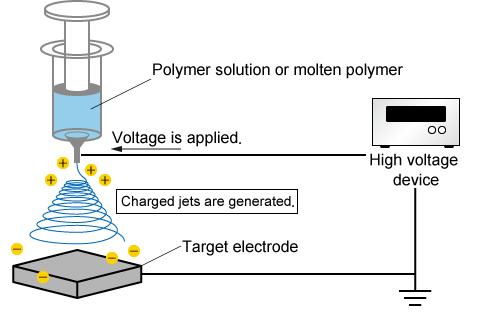

In field spinning, a polymer solution or molten polymer is placed in a syringe, and the polymer solution is injected while applying a high voltage. When the voltage exceeds a threshold value, the repulsive force of the electric charge overcomes the surface tension of the polymer droplets, and a jet of charged material is generated. By accumulating these jets, ultra-fine polymer fibers are formed.

DC high-voltage power supplies with positive polarity output of about 10 kV to 30 kV can generally be used. Depending on the polymer solution you want to static electricity, thickness of the fiber, and speed to fly the fiber to the target electrode, the higher voltage such as up to 50 kV or more, DC high voltage with negative polarity, and a high-voltage amplifier can also be required.

Matsusada Precision has a strong sales performance for electrospinning as well. Please contact our sales office for details.

Matsusada Precision is proposing a high-voltage power supply that can be used as a voltage source for injecting polymer solutions.

- Related words:

-

- electrospinning

- polymer

- ultrafine fiber

- covid-19

- N95

- Mask

Recommended products

Matsusada Precision provides high-voltage power supplies that are applied during polymer injection.