Capacitor testing involves measuring the performance of capacitors through various evaluations. These tests, specified in standards such as JIS C 5101-1:2019 and IEC 60384-1:2016, include the dielectric withstand test, leakage current measurement, and destructive tests.

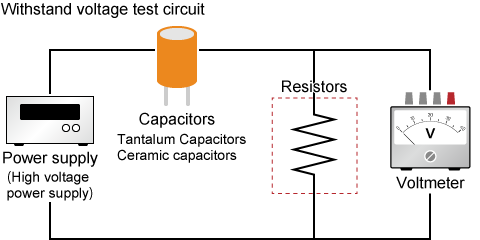

Withstand voltage tests are commonly conducted on tantalum and ceramic capacitors. To ensure reliability, these tests apply a voltage 1.5 to 2 times the capacitor's rated voltage. This process requires a high-voltage power supply capable of delivering voltages beyond those of standard power supplies.

The leakage current measurement test determines the amount of current that flows when a specified voltage is applied. This is done by applying a high voltage with a power supply and measuring the resulting leakage current.

A destructive test involves applying a progressively higher-than-rated voltage to a capacitor to determine the voltage at which it fails. When a capacitor fails, it can create a short circuit, causing a dangerous overcurrent condition. To address this, Matsusada Precision offers models with a built-in protection function that automatically cuts off the output during an overcurrent event.

We offer a wide range of high-voltage power supplies suitable for all types of capacitor testing, including destructive tests.

Withstand voltage test circuit

- Related Terms:

-

- Electrolytic capacitors

- Ceramic capacitors

- Film capacitors

- Withstand voltage test

- Leakage current

- Destructive test

- Overcurrent

- High voltage

- Capacitor Charging

Recommended products

Matsusada Precision has models with a protection function that cuts off the output in case of overcurrent. We handle high-voltage power supplies, which are available for various types of capacitor testing as well as destructive testing.