Vacuum technology is familiar in daily life, commonly used for vacuum-packing food products. In industrial settings, it is essential for semiconductor manufacturing, thin film deposition, and electron microscopy. This article explains the definition of a vacuum, how it is created, and how it is measured.

What is a vacuum?

Generally, "vacuum" implies a space with no air. While a space entirely devoid of matter is called a perfect vacuum (absolute zero pressure), strictly speaking, creating such a state is impossible. Even in the most advanced systems, some gas molecules remain.

For this reason, the Japanese Industrial Standard (JIS) defines a "vacuum" as a "state of space filled with gas at a pressure lower than the normal atmospheric pressure," in other words, a "negative pressure". Thus, it is essential to note that "vacuum" in the general sense and "vacuum" in an industrial context have different meanings.

This section describes the industrial vacuum.

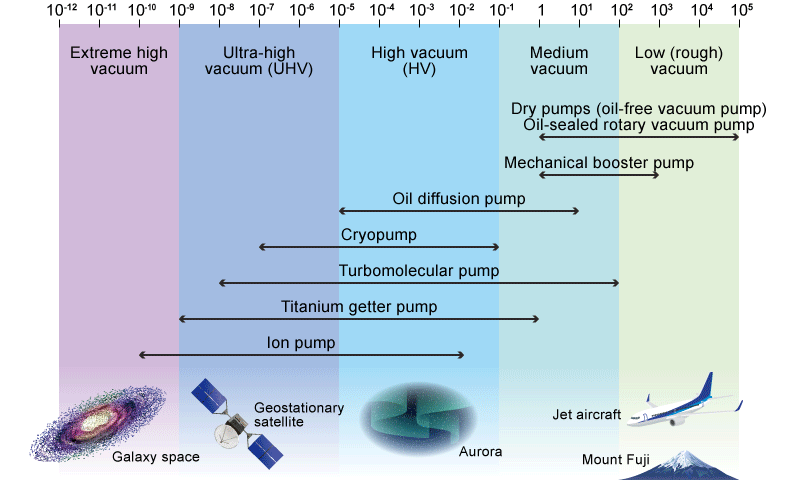

According to the JIS definition, a vacuum is divided into five categories according to atmospheric pressure.

- • Low (rough) vacuum 105Pa to 102Pa

- • Medium vacuum 102Pa to 10-1Pa

- • High vacuum (HV) 10-1Pa to 10-5Pa

- • Ultra-high vacuum (UHV) 10-5Pa to 10-8Pa

- • Extreme high vacuum 10-8Pa or less

In a vacuum, the absence of air prevents the growth of bacteria and allows processing and observation without interference from gas molecules. In many cases, primarily industrially, vacuum conditions are used for the latter purpose. The exclusion of gaseous molecules increases the distance a molecule can proceed without colliding with other molecules.

This means that thin films and other deposition processes are easier to perform.

Vacuum Applications

Vacuum is used in a variety of applications. Typical examples of everyday items include vacuum-sealed food by deaeration (degassing) and freeze-drying foods by vacuum drying. Industrially, it is also used in vacuum deposition, vacuum plasma processing, and Scanning Electron Microscope (SEM).

Vacuum classifications and typical applications are shown below.

- Low vacuum:

-

Besides vacuum chucks for gripping thin films and objects in production processes, they are also used for vacuum-forming resins. It is often used to adsorb objects using the difference from atmospheric pressure or to prevent excess air from entering the workpiece.

- Medium vacuum:

-

Used for deposition equipment. Applications include CVD and plasma processing equipment and vacuum deposition. It improves film adhesion and quality by reducing the number of gas molecules from the chamber being processed that are not used for film deposition.

- High vacuum:

-

Similar to medium vacuum, this is often used for deposition equipment. CVD, sputtering, ion plating equipment, and ion etching equipment also use high vacuum. High vacuum is also used in the freeze-drying process in food processing.

- Ultra-high vacuum:

-

Used in large accelerators for subatomic research, surface analysis equipment, molecular beam deposition equipment, space chambers, etc. For example, when accelerating particles, gas molecules in the air get in the way and prevent the particles from accelerating. Therefore, a vacuum is used to exclude anything other than the particles and molecules to be manipulated from the chamber.

- Extreme high vacuum:

-

Extreme high vacuum is currently limited to specialized scientific research, such as particle physics, and its broader industrial applications are still being explored. Advanced vacuum pumps and measurement instruments are under development to reliably achieve this state.

How to create a vacuum

A vacuum is obtained by exhausting gas molecules in the space using a vacuum pump. The type of vacuum pump that can be used depends on the degree of vacuum.

- Low vacuum:

-

Oil-sealed rotary vacuum pumps, dry pumps (oil-free vacuum pumps), etc. are used. Since a low vacuum can be achieved if some air can be expelled, most use a mechanical mechanism to remove air. In everyday use, a simple manual vacuum pump is used.

- Medium vacuum:

-

Oil-sealed rotary vacuum pumps and mechanical booster pumps are used. As with low vacuum, this can be achieved with a mechanical pump. However, unlike low vacuum, the pump should be selected with attention to the Knudsen number, indicating whether the gas flow can be treated as a statistical mechanics or a continuum mechanics formulation of fluid dynamics.

- High vacuum:

-

Turbomolecular pumps, oil diffusion pumps, and molecular drag pumps are commonly used. Unlike low or medium vacuum ranges, simply mechanically exhausting air is insufficient. It becomes necessary to manage gas behavior at the molecular level, for example, by using momentum transfer in turbomolecular pumps to repel gas molecules. To achieve high vacuum, a roughing pump is typically used to lower the pressure before engaging the high-vacuum pump.

- Ultra-high vacuum:

-

Sputter ion pumps, titanium getter pumps, non-evaporative getter pumps, etc., are used. When trying to obtain an ultrahigh vacuum, rather than exhausting air, the mechanism is to capture or adsorb gas molecules onto a surface, effectively removing them from the space or other means. For more information on ion pumps, see "Ion Pumps - Matsusada Precision Power Supply Applications"

- Extreme high vacuum:

-

Pumps for obtaining Extreme high vacuum are still under research and have not been put into practical use.

How to measure vacuum

When using a vacuum, it is necessary to ensure that the absolute pressure inside the chamber is at the desired vacuum level. Therefore, a vacuum gauge to check the vacuum is very important. Vacuum classifications and vacuum gauges used are as follows.

- Low vacuum: liquid column manometer, diaphragm manometer

- Medium vacuum: McLeod gauge, thermal conductivity vacuum gauge (Pirani gauge)

- High vacuum: Ionization vacuum gauge, Penning gauge (cold cathode ionization gauge)

- Ultra-high vacuum: Bayard-Alpert hot cathode ionization gauge (B-A gauge)

In low vacuum, pressure is usually measured based on the differential from atmospheric pressure. Conversely, in high vacuum and above, measurement involves determining the density of remaining gas molecules. For instance, ionization gauges apply a high voltage to discharge gas molecules, measuring the resulting ion current to determine pressure.

Reference Link: Vacuum Gauges - Matsusada Precision Power Supply Application