How an ion pump works

An ion pump is a type of vacuum pump used to create an ultra-high vacuum. They are also called sputter ion pump or noble pump. There are several types of vacuum pumps, including ion pumps, as follows.

| Low vacuum range | High vacuum range | |

|---|---|---|

| Pump type | Rotary pump Diaphragm Pump Dry Scroll Pump |

Ion pump Turbomolecular Pump Cryopump Oil Diffusion Pump |

| Fluid | Viscous flow | Molecular flow |

| Effect of Conductance | Small | Large |

| Exhaust Diameter | Small | Large |

| Flange example | NW16-40 | ICF70-406 |

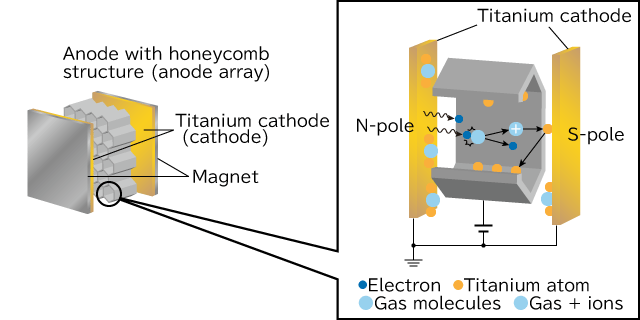

The ion pump consists of a powerful magnet, an anode (anode array) with a honeycomb structure, and a cathode (cathode) made of titanium arranged to sandwich the anode. Therefore, it is characterized by the fact that it has no mechanical moving parts like a rotary pump.

When a cold cathode discharge occurs in a magnetic field, the electrons emitted from the electrodes move back

and forth between the cathodes in a spiral motion due to the action of the magnetic field.

When the electrons collide with gas molecules, the gas molecules are ionized and become ions. When these ions

collide with the cathode, they sputter (knock out) the titanium atoms on the surface of the cathode and embed

them in the cathode.

In addition, the sputtered titanium atoms form a clean titanium film, called a getter film, on the anode,

cathode, and inner walls of the pump. Since the sputtered titanium atoms are chemically active, they adsorb

surrounding gas molecules as they form the film.

Gases such as hydrogen, oxygen, nitrogen, and carbon monoxide, as well as inert gases such as helium, are

ionized and thus embedded in the cathode or adsorbed by the titanium atoms. As a result, the number of gas

molecules in the surrounding environment decreases. In this way, the ion pump creates a vacuum state.

(1) Electrons are ejected from the titanium cathode by high voltage and move

back and forth between the cathodes in a spiral motion.

(2) The electrons collide with gas molecules, and the gas molecules are ionized

to form ions.

(3) The ions collide with the titanium cathode, sputtering (knocking out) the

titanium atoms and embedding them in the cathode.

(4) In addition, the sputtered titanium atoms form a titanium film called a

getter film, which adsorbs gas molecules.

Rather than using a mechanical mechanism to pump air, as in the case of a centrifugal pump that pumps water, a

vacuum is created by chemically reacting and consuming the air present.

If you imagine an elementary school science experiment in which a candle is burned in a bottle lying on the

surface of the water, water is sucked up in proportion to the oxygen consumed, it will be easier to imagine how

the ion pump works. When there is no more gas, the electrical resistance between the anode and cathode rises.

This causes the current to stop, and the completion of pumping can be confirmed.

The ion pump is characterized by its ability to achieve a high degree of vacuum regardless of the type of gas.

For this reason, they are used in transmission electron microscopes, electron beam lithography equipment,

accelerators, and semiconductor manufacturing equipment.

Features of ion pumps

The advantages and disadvantages of ion pumps are as follows.

- Simple configuration of anode, cathode, and magnetic field with no mechanical moving parts

- No mechanical vibration or noise, and no effect on the operation of other equipment

- Difficult to break down because there are no mechanical moving parts

- Ultra-high vacuum (10-10Pa) can be achieved.

- Automatically stops when a vacuum is achieved, eliminating the need for a vacuum gauge.

- Unlike rotary pumps and oil diffusion pumps, no oil is used.

- Does not contaminate the exhaust system even when stopped suddenly, and is suitable for unmanned operation.

- Can be used only with a power supply, so it can be installed in any position or method.

- Energy saving because the power consumption decreases as the air pressure decreases.

- Requires high voltage due to cold cathode discharge between anode and cathode.

- It is difficult to evacuate a large flow of gas, and can only be used from a high vacuum (around 1 Pa).

- Since roughing out is necessary, other pumps must be used in combination.

- Baking is required before pumping to remove impurities adhering to the inside of the pump.

- Since the cathode is sputtered, it has a lifetime.

One of the major advantages of ion pumps is that they can achieve a high vacuum without mechanical vibration or

noise because of their simple mechanism of applying voltage to electrodes in a magnetic field. For this

reason, they are widely used as vacuum pumps for electron microscopes and semiconductor manufacturing equipment,

which require both high vacuum and fine control.

Ion pumps themselves are not very large, and even the largest ones are usually small enough to fit on a

desk.

Since the power consumption drops when there is no more gas that can be exhausted, and there is no backflow of

oil or other contaminants to contaminate the area being exhausted even if the pump should stop, it is suitable

for unattended operation for long periods of time, and is also widely used as a vacuum pump to maintain a

vacuum.

On the other hand, one disadvantage is that it is difficult to pump at high flow rates. In most cases, the

start-up pressure of ion pumps is around 1 Pa. Therefore, in order to obtain an ultra-high vacuum, it is common

to create a high vacuum state with another pump in advance, and then use the ion pump to perform the final

pumping and maintenance.

In addition, if impurities are adsorbed inside the pump, they will interfere with the pumping, so baking must be

performed beforehand to remove the impurities. In addition, the titanium of the cathode is sputtered and

deposited on the inner walls of the pump and other parts, so it has a life span. The equipment needs to be

replaced at the appropriate time. Another disadvantage of ion pumps is that they require high voltage.

Commercially available ion pumps are made to operate at 3kV, 5kV, or 7kV. In addition, power supplies with

currents and capacities ranging from tens of watts to hundreds of watts are used, depending on the pumping speed

and capacity.

Matsusada Precision has a lineup of modular power supplies and dedicated power supplies for ion pump operation. These power supplies not only supply power to the ion pump, but can also monitor vacuum conditions by accurately detecting minute changes in current.

-

ULVAC, Inc.

https://showcase.ulvac.co.jp/ja/products/high-vacuum-pump/ -

Canon ANELVA Inc.

https://anelva.canon/business/component/pu_detail01.html -

Agilent Technologies, Inc. (formerly Varian)

https://www.agilent.com/en/product/vacuum-technologies/ion-pumps-controllers -

Gamma Vacuum, Inc.

https://www.gammavacuum.com/

- Related words:

-

- Vacuum pump

- ultra-high vacuum

- Turbomolecular Pump

- Cryopump

- Oil Diffusion Pump

- Rotary pump

- Diaphragm Pump

- Dry Scroll Pump