What is Programmable Power Supply?

Programmable power supplies are essential tools for engineers, researchers, and manufacturers in various applications. These devices provide precise and accurate control over voltage and current output levels, making them ideal for testing and powering electronic components and circuits.

When selecting the right programmable power supply for your needs, Matsusada Precision stands out as a top choice.

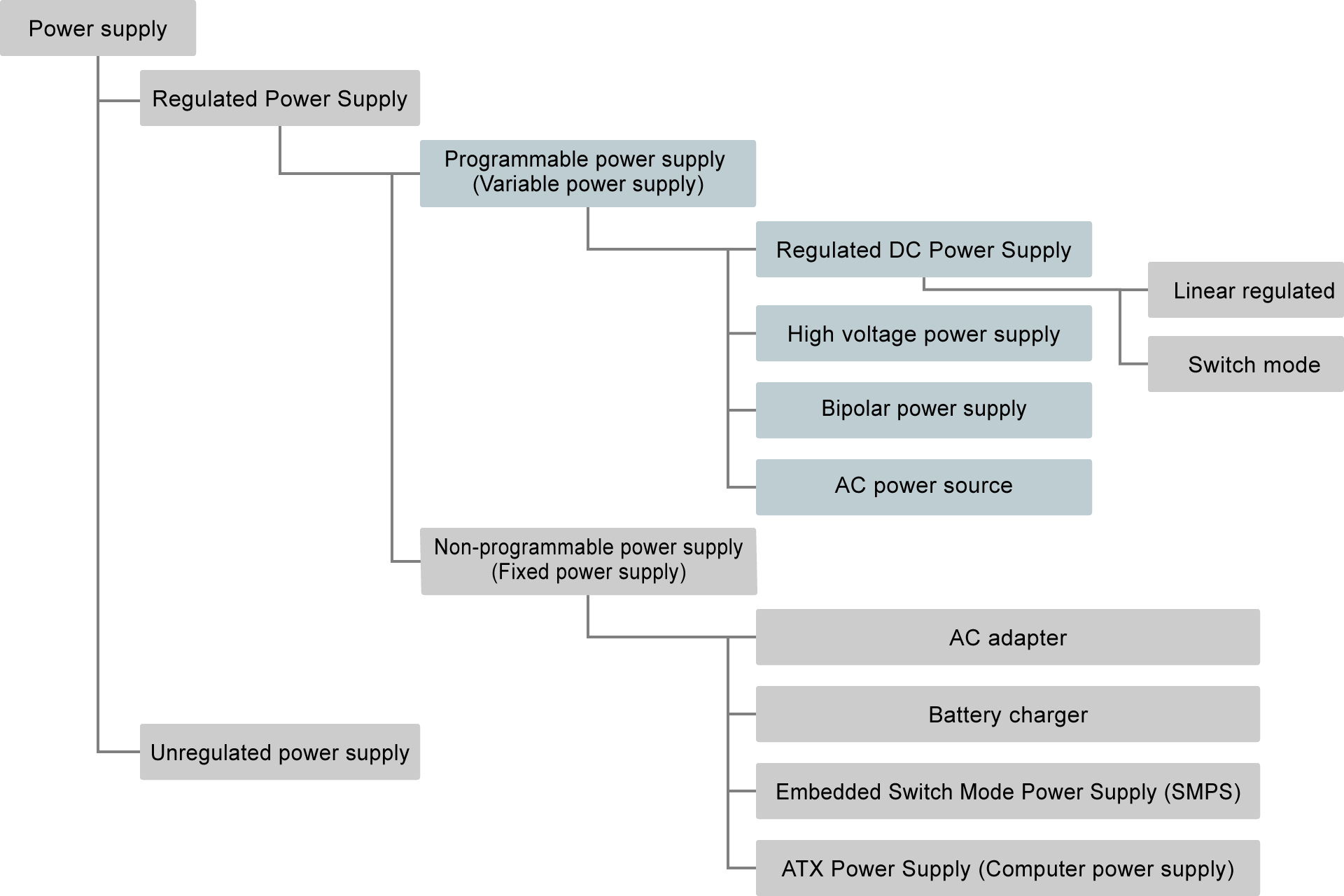

At its core, a programmable power supply, often referred to as a programmable bench power supply, is a device used in electronics and electrical testing and development to provide a controllable and adjustable source of electrical power. Unlike power supplies that provide a fixed voltage, such as a wall outlet, AC adapter, or battery charger, programmable power supplies allow users to set and customize the output voltage, current, and other parameters.

What is the difference from Variable/Adjustable Power Supply?

The terms "programmable power supply," "variable power supply," and "adjustable power supply" are often used interchangeably as they all refer to electronic devices or sources that can provide a variable output voltage or current, allowing you to change the power supply's settings across a wide range. They all essentially serve the same fundamental purpose of providing variable voltage and current. However, the term "programmable" is sometimes used to highlight that the power supply can be controlled remotely via digital interfaces, which is particularly useful for automated testing and applications that require precise control and monitoring.

Types of Programmable Power Supplies

There are four basic types of programmable power supplies. These programmable power supplies cater to various needs, from basic voltage and current adjustments to more advanced and specialized requirements in both DC and AC electrical systems.

Programmable DC Power Supply

This power supply allows users to set and control the output voltage and current in direct current (DC) applications. It is widely used in electronics testing, circuit prototyping, and research and development.

Programmable AC Power Source

Programmable AC power sources provide adjustable output voltage and current in alternating (AC) waveforms. They are essential for testing devices that operate on AC power, such as appliances and industrial equipment.

Digital Programmable Power Supply

Digital programmable power supplies offer precise control and monitoring through digital interfaces and an encoder-type knob on the front side. Users can set parameters digitally, making them ideal for automated testing and remote control applications.

Analog Programmable Power Supply

Analog programmable power supplies use analog potentiometer controls, such as knobs and dials, to adjust output parameters. While less precise than their digital counterparts, they are still valuable for certain applications and may be preferred for their simplicity.

Benefits of Using Programmable Power Supply

Using a programmable power supply offers several benefits in various applications, making it a valuable tool for engineers, researchers, and manufacturers. Here are some of the key advantages of using a programmable power supply:

| Precision Control | Programmable power supplies allow precise and accurate control over voltage and current output levels. This level of control is crucial for testing and powering electronic components and circuits, ensuring that they operate within specified parameters. |

|---|---|

| Flexibility | Users can easily customize the voltage and current settings to match the requirements of different devices or experiments. This flexibility is especially important in research and development, where diverse testing scenarios are common. |

| Automation | Many programmable power supplies can be automated through digital interfaces and software control. This automation streamlines testing processes, reduces the risk of human error, and enables unattended, long-term experiments. |

| Remote Operation | Remote control capabilities, often through interfaces like USB, Ethernet, or GPIB, allow users to operate the power supply from a distance. This is useful for applications with limited physical access to the power supply or remote monitoring and control. |

| Sequencing and Profiling | Programmable power supplies often support sequencing and profiling, allowing users to define and execute complex voltage and current waveforms over time. This is valuable for simulating real-world operating conditions or stress testing. |

| Overvoltage and Overcurrent Protection | Many programmable power supplies include safety features like overvoltage protection (OVP) and overcurrent protection (OCP) to safeguard connected devices from potential damage due to unexpected voltage or current spikes. |

| Efficiency | Programmable power supplies can be designed with high efficiency, reducing energy consumption and heat generation. This is especially important in applications where power efficiency is a concern. |

| Time and Cost Savings | Programmable power supplies can save significant time and labor costs by automating tests and experiments. They also reduce the need for manual intervention and supervision. |

| Versatility | Programmable power supplies can be used in various applications, from electronics testing and circuit prototyping to battery research and product development. This versatility makes them valuable tools for various industries and research fields. |

| Data Logging and Monitoring | Some programmable power supplies offer data logging and real-time monitoring capabilities, allowing users to capture and analyze performance data during experiments or tests. |

Applications of Programmable Power Supplies

Programmable power supplies find applications in various fields, including laboratory work, test and measurement (T&M), research and development (R&D), and product manufacturing. Here are some specific applications within these domains

Laboratory

Programmable power supplies are essential tools in laboratories for testing electronic components, prototyping circuits, and conducting materials science experiments. They also play a role in educational settings for hands-on learning experiences.

Test and Measurement (T&M)

In T&M applications, programmable power supplies are used for functional testing of electronic devices, environmental testing, and instrument calibration, ensuring accurate measurements and product quality.

Research and Development (R&D)

Engineers and researchers rely on programmable power supplies during product development, especially for battery research, sensor development, and testing new technologies to validate performance and behavior.

Product Manufacturing

Programmable power supplies are integrated into manufacturing processes for quality control, automated testing, end-of-line testing, and production debugging, ensuring products meet electrical performance standards before reaching consumers.

Specifications of Programmable Power Supply

The primary specifications that can help you choose the right programmable power supply for your needs (apart from the input/output voltage range and current and power rating) or compare different programmable power supplies are:

Ripple Noise

Ripple noise is any unwanted variation and fluctuation that distorts the smooth DC output signal, like ripples breaking on a water surface when a stone is thrown. It influences the overall accuracy and precision of any programmable power supply, particularly switching power supplies. The supplies rated for a low ripple noise factor will be more accurate and precise, which is important for sensitive signal processing applications where noise tolerances are usually low. It's calculated in V or mV (peak to peak). The ripple noise requirements may vary based on use cases. If you want a programmable supply for medical equipment or precision instrumentation, it's important to consider and account for the ripple noise the supply is rated for (for different voltage levels). You may have more leeway in use cases like DC motors and power applications.

Stability

The stability of a programmable power supply can be defined as its ability to maintain a consistent and reliable output voltage over time (at different voltage levels); even if operating conditions change, load varies, and there is significant variation in external factors like temperature. The stability is usually calculated in PPM per Hour, which essentially tells you how much the operational voltage may drift from the nominal voltage (standard/rated voltage) per hour (within standard working conditions). So, a programmable power supply operating at 100 kV, with a stability factor of 50 PPM per Hour, may only offer a voltage variation of 5 V in an hour. So, a lower PPM would mean higher stability.

A high-stability, programmable power supply may offer a steady voltage with minimal fluctuation over long periods of operation, but only if it's operating within the parameters defined by the manufacturer. Significant differences in temperature, load conditions, and input voltage/power may lead to higher voltage fluctuations.

Efficiency

The efficiency of a power supply is the ratio of how much input power is effectively converted into output. High-efficiency power supplies waste less power, while low-efficiency supplies waste a lot of input power, which also results in higher heat generation and may lead to faster degradation of the components. This has more to do with whether it's a switching power supply or linear regulated power supply than its programmability.

The issue may be amplified when you are operating a programmable power supply in high voltage/high amperage conditions, although both may impact the supply and its performance differently. At high voltages, core losses in power supply transformers may be amplified, reducing its efficiency. At high amperage, conduction losses may negatively impact the efficiency of the programmable power supply.

A low-efficiency, programmable power supply may waste more power, generate more heat, and may require more comprehensive cooling measures to function properly.

Power density

Power density is the measure of the amount of power produced per unit volume or weight. Basically, it's the calculation of how much power it produces for the space it occupies or its weight. The power density requirements depend upon different use cases. If you need a programmable power supply for an aviation use case (Drone, satellite, etc.), you may want a supply that produces the requisite power while weighing as little as possible. However, for a stationary medical instrument, you may have a higher weight tolerance, but you might need a small form factor. Programmable power supplies that can accommodate higher voltages and amperage usually have larger and heavier components (transformer, inductors, insulation, etc.), so power density is more of a concern compared to programmable supplies that operate in low voltage/amperage range.

Safety

Safety is an important consideration when it comes to any programmable power supply. However, it becomes even more prominent for programmable supplies capable of handling (input) or producing (output) higher levels of current or higher voltages. That's because, without the right safety measures in place, high voltages and currents may have a higher chance of harming components, circuits, and individuals than low-voltage supplies.

So, it's important to look into three safety elements: Standards, features, and manufacturer recommendations. The standards may include UL-recognized (for Canada and the US) and CE for European safety standards. Features may include better insulation, safe connectors, and control systems with overcurrent, overvoltage, and other protections. Lastly, you should also familiarize yourself with the safety recommendations of the manufacturer.

Line regulation

Line regulation is a power supply's ability to maintain a steady output voltage when input voltage changes. It's calculated as a percentage of the rate of change in output based on change in input. So, if a programmable power supply has a line regulation of 0.01% for a output voltage range (say 0 to 36 V), the output voltage may change by just 3.6 mV(0.0036 V) for a line voltage change of 85 Vac to 115 Vac.

Load regulation

Load regulation is how much output voltage may vary when there is a change in load. It's calculated as a percentage of change in output voltage against nominal/rated voltage. In most cases, it's often the same or lower than the line regulation of a power supply, but unlike line regulation, it's not denoted with ± notation but rather just as a percentage change. Load regulation is an important tolerance to consider in use cases where load current may vary over time or under changing conditions.

Versatility

Versatility in a Programmable power supply is how many use cases it can support based on its output voltage range, current range, frequency control, output modes (constant current or voltage), number of output channels, and programmability. Factors like safety, size, weight (and power density), and even the communication channels it offers can impact its versatility. This is one of the areas where programmable power supplies shine because they offer much more control over output parameters.

Selecting the Right Programmable Power Supply

Selecting the right programmable power supply is crucial for various applications. Here are three key factors to consider when making your choice:

Voltage and Current Ranges

To select the right programmable power supply, determine the voltage and current ranges required for your specific application. Ensure the power supply can provide the necessary output levels to meet your testing or powering needs. It's essential to have a power supply that can deliver both the minimum and maximum values you might need without compromising precision or safety. However, it is important to exercise caution by not selecting a power supply with excessively high voltage or current capabilities, as this could lead to a reduction in the accuracy of the delivered voltage or current.

Programmable Features

You also need to consider the programmable features the power supply offers. This includes the ability to set and control voltage and current limits, as well as any additional programmable functions like ramping, sequencing, or remote control options. Choosing a power supply that aligns with your automation and testing requirements is important.

Output Stability

Assess the power supply's output stability, which refers to its ability to maintain consistent voltage and current levels over time and under varying load conditions. You must look for specifications such as load and line regulations to understand how well the power supply can maintain stability. A power supply with excellent stability characteristics is essential in applications requiring precise and stable power output.

Ultimately, selecting the right programmable power supply involves matching its specifications and features with your specific application's requirements. Careful consideration of voltage and current ranges, programmable capabilities, and output stability will help ensure that the chosen power supply meets your needs effectively and reliably.

Matsusada Precision's Programmable Power Supplies

Matsusada Precision's Programmable Power Supplies come in both DC and AC variants, offering diverse solutions to meet your specific needs.

DC Power Supplies

These are known by various names like DC power supplies, AC to DC power supplies, regulated power supplies, or programmable DC power supplies. Matsusada Precision's DC power supplies are designed for excellence, focusing on compactness, low noise, and high power output.

The product range spans from palm-sized precision DC power supplies to benchtop and high-power rackmount/cabinet models.

We cater to various applications, from ultra-compact units with original high-efficiency switching methods to ultra-low ripple DC-regulated power supplies. We also offers high-power DC-regulated power supplies with capacities reaching 120 kW, tailored for communication equipment and evaluation needs in fields like energy/environment, vehicles/aerospace, semiconductors, bio/medical, electronics, and industry.

We swiftly accommodate customers with custom specifications, reducing their development cycles. Matsusada Precision's DC power supplies are relied upon globally in research institutes and factories.

AC Power Sources

AC power has unique characteristics of alternating positive and negative sides at 50 Hz and 60 Hz. Matsusada Precision's Programmable AC power sources are versatile and high-performance, handling a wide range of functions and providing substantial output in a compact form factor. Thanks to our original switching amplifier system, these power sources are designed to be compact and efficient. They can output AC + DC, support three-phase output, and even simulate momentary power interruptions.

These AC power sources can be used for testing motors, solar inverters (PV inverters), various AC input devices, and production lines and for cost-effective frequency conversion.

For those needing higher voltage solutions, Matsusada Precision also offers high-voltage power supplies.

Whether you need precise DC power or versatile AC power sources, Matsusada Precision has you covered with high-quality and reliable solutions suitable for OEM or laboratory applications worldwide.

Matsusada Precision: Driving Progress with Customizable Power Supplies

Programmable power supplies offer precise control, flexibility, automation, and a range of features that enhance efficiency and productivity in various applications. Their precision, flexibility, and automation capabilities enable the development of cutting-edge technologies, from semiconductors to renewable energy systems.

As Matsusada Precision continues to push the boundaries of innovation, programmable power supplies will remain essential tools, facilitating the testing, research, and manufacturing that drive progress.