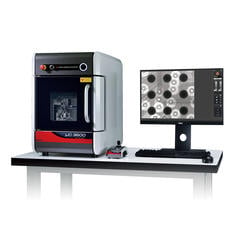

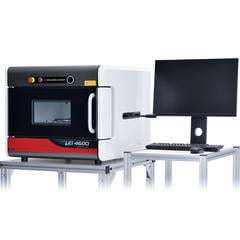

Benchtop

X-ray Inspection Systems

(Top View Type)

Inquiry

Matsusada Precision is a leading developer and manufacturer of advanced X-ray non-destructive testing (NDT) solutions. Incorporating our proprietary microfocus X-ray source technology, these systems deliver high-resolution imaging for precise internal analysis. Designed for engineers and researchers, our benchtop systems facilitate rapid quality control and failure analysis, supporting innovation and ensuring high product reliability.

Our benchtop X-ray inspection systems provide non-destructive observation of internal structures, ranging from compact, high-definition models to large, high-transmission systems suitable for diverse applications. These systems are essential for industrial tasks such as inspecting batteries, capacitors, BGA connections, and wire bonding. They are also widely used in medical and biological fields for the non-destructive observation of various specimens.

These systems are ideal for inspecting visually inaccessible components, including BGAs, QFNs, SONs, DFNs, and LGAs, as well as connectors used in automotive ECUs. Key inspection capabilities include detecting solder shorts, voids, BGA ball misalignment, and size variations. By visualizing these hidden defects, the systems ensure the reliability of high-density mounting processes.