What is automatic control?

According to the Japanese Industrial Standards (JIS), control is defined as "the application of a required operation to an object in order to make it conform to a certain purpose.

For example, consider a case in which you want to maintain a constant temperature in an aquarium for breeding tropical fish. The water in the aquarium is heated by heaters, but the temperature is affected by outside temperatures and other factors, so the output of the heaters must be constantly adjusted to achieve the proper temperature.

In such cases, keeping the temperature of the aquarium constant is the "purpose", and adjusting the heater output is the "required operation". And the entire system of detecting water temperature and outside temperature and adjusting heater output is called "control".

Control is broadly classified into "manual control," in which human intervention is required, and "automatic control," in which machines perform autonomously. There are several types of automatic control depending on the purpose and mechanism, but the most common are sequence control, feedback control, and feedforward control.

Typical methods of control include

- ●Sequence control

-

This is a control method in which each stage of control proceeds sequentially according to a predetermined sequence or condition. A typical example is a washing machine that operates in the order of "wash, rinse, dehydrate," and is used in situations where a fixed procedure is repeated exactly.

- ●Feedback control (FB)

-

The control quantity (temperature, etc.) is measured by a sensor and the result (current value) is compared with the target value. The manipulated variable is then adjusted to eliminate the difference (deviation). PID control is a typical example of this feedback control.

- ●Feedforward control (FF)

-

In contrast to feedback control, feedforward control is a control method that "takes steps ahead of time before results are obtained. The disturbance (e.g., a cause of temperature change) is directly measured, and operations are performed in advance to counteract the effect before the effect appears in the control value. The advantage of this method is that it responds very quickly, but it has the drawback that it cannot respond to unpredictable disturbances, and if the prediction model is not accurate, errors will remain. For this reason, it is often used in combination with feedback control, as described below.

Feedback control

Typical feedback control methods include the following.

ON/OFF control

This control is performed by simply turning the switch on and off. A typical example is a thermostat.

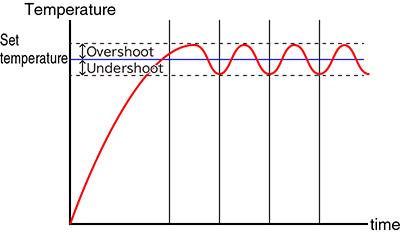

For example, a heater with a thermostat is placed in an aquarium filled with water. Since there are only ON and OFF operations, the output value moves up and down in the vicinity of the set value. When the power is turned on, the heater stays on until the water temperature reaches a pre-determined level. If the water temperature exceeds the specified temperature, the thermostat will turn off the switch, and if it falls below the temperature, the thermostat will turn the switch on again.

This phenomenon of going above or below the "setpoint" is called overshooting or undershooting. Because it is a very simple mechanism with only two operating volume options (0% and 100%), it is utilized in a variety of devices and locations, such as the heating mechanism of humidifiers.

Proportional control

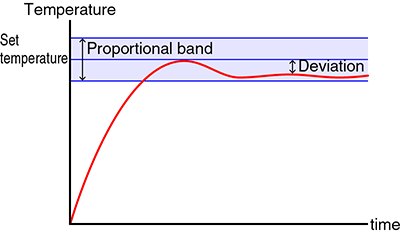

Unlike ON/OFF control, this control continuously changes the operating volume in response to changes in the control volume. A few percent is set as the proportional band centering on the target set value, and in the proportional band, the operation amount is proportional to the deviation between the current value and the set value.

Taking the water in the aquarium and the heater as an example, the heater heats at 100% output until the water temperature reaches the proportional band, and the proportional control is performed from the point when the water temperature reaches the proportional band. During proportional control, the output is 100% at the lower threshold of the proportional band, 50% at the target value, and 0% at the upper threshold.

Compared to ON/OFF control, there is less overshoot and undershoot, and equilibrium is achieved somewhere in the proportional band. However, it is also characterized by the fact that the stability of control results varies greatly depending on the setting of the proportional band. The guideline for the proportional band is about 2 to 10%, but be careful because it depends on the device.

Proportional-integral-derivative (PID) controller

PID control is one of the feedback controls and is a very common control that is currently used in so many places. P stands for Proportional, I for Integral, and D for Derivative. PID control is the addition of differential and integral control to proportional control.

P operation (proportional control) combined with I and D operation. I-operation and D-operation do not operate independently. The I-operation is responsible for reducing the offset generated during proportional control, while the D-operation is responsible for responding to disturbances.

Three operations of PID control

We explained that PID control is based on a combination of P, I, and D operations. In this section, we will explain specifically how each of these operations works.

- • P-operation (Proportional)

-

In PID control, P operation (proportional control) is the basic operation. As described in the previous section, proportional control is control in which the deviation between the set value and the current value is proportional to the operating volume within a proportional band.

- • I-operation (Integral)

-

I operation is controlled by time integration. In P operation, the set value and the current value do not match due to load fluctuations or inherent characteristics of the equipment, and a permanent discrepancy (deviation) may occur. This is called offset (residual deviation).

Therefore, "PI" operation, which combines "P" operation with "I" operation, can be used to automatically eliminate the offset that has occurred. Using water in an aquarium as an example, PI operation is the fine-tuning of the water to achieve equilibrium at a temperature as close to the set value as possible.

The I operation adjusts the operation amount of the P operation by proportionally accumulating the offset time and the operation amount. If the integration time is short, strong integration will be applied, and the deviation can be corrected in a short time, but hunting, a phenomenon where the current value fluctuates around the set value is likely to occur.

Therefore, the point of control is to set the integration time appropriately.

- • D-operation (Derivative)

-

D-operation is a control to respond to sudden changes due to disturbances, etc., and to correct the output. Based on the example of an aquarium, even if the water temperature is stable once, it will change due to external factors such as a sudden rise or fall in the outside air temperature.

In such a case, the P operation adjusts the output value in proportion to the deviation between the current value and the target value, whereas the PD operation plus the D operation adjusts the output value in proportion to the speed of temperature change. As soon as a trend in temperature change is detected, the corresponding control is performed, shortening the time required for stabilization at the original value.

PID Control Performance Metrics

To objectively determine if the results of PID parameter tuning are "good" or "bad," the following metrics are used.

Rise Time: The time it takes for the controlled variable to reach a specific range of the target value (e.g., 10% to 90%). This indicates the speed of the response.

Overshoot: The amount by which the controlled variable exceeds the target value. If this is large, it can put a strain on the system.

Settling Time: The time it takes for the controlled variable to converge and stabilize within a certain range (e.g., ±5%) of the target value after an overshoot.

Offset / Residual Deviation: The persistent difference between the target value and the actual process variable in steady-state.

Excellent tuning means balancing these metrics according to the requirements of the system being controlled.

Adjusting PID Parameters (Tuning)

To make PID control function effectively, it is essential to optimize (tune) the "PID parameters," which determine the strength of the P, I, and D actions, to match the controlled object.

Hunting: A phenomenon where the controlled variable continues to oscillate around the target value when parameters are inappropriate.

Typical Tuning Methods: In addition to manual adjustment based on experience, there are methods that use formulas, such as the Ziegler-Nichols method and its improved version, the CHR method.

Auto-tuning: Recent temperature controllers are equipped with an "auto-tuning function" that automatically calculates the optimal PID parameters at the touch of a button. Internally, this function executes a tuning method programmatically, such as the limit sensitivity method.

Implementation and Application of PID Control

Advanced Forms of PID: Basic PID control has challenges, such as output disturbances when the setpoint changes abruptly. To address this, improved versions have been devised, such as PI-D control (where the derivative action is applied to the process variable instead of the error) and I-PD control (where proportional and derivative actions are on the process variable).

Anti-Windup: The manipulated variable has physical limits (e.g., a valve can only be 0% to 100% open). If a large error persists, the integral term can accumulate excessively, causing the output to become stuck at its limit. This is known as "windup." An "anti-windup" process to prevent this is an essential implementation technique for reliable control.

Program Implementation: When implementing PID control on a computer, the process involves repeatedly calculating the error at short time intervals (the control period) and outputting the sum of the P, I, and D terms as the manipulated variable.

Example of PID control

PID control is used in a great many fields, including production, such as temperature control, motor control, and robot control. In addition, the equipment, where PID control is used, is mainly equipment with many disturbance factors or equipment that frequently changes target values. For example, it is widely used in electric furnaces. PID control units are sold for integration into equipment, and these may be used to build production facilities and other equipment.

In recent years, the thermal cycler used for Polymerase Chain Reaction (PCR) has been attracting attention as a device that uses PID control. In PCR, the temperature of the reaction solution must be manipulated up and down at a specified temperature in order to replicate the DNA fragment. At this time, PID control is used to adjust the temperature of the PCR solution.