Lithium-ion batteries (LIB, LFP, NMC) consist of alternating layers of cathode plates, anode plates, and separators inside a case. X-ray inspection systems are used to inspect the quality of lithium-ion batteries. As internal defects of the lithium-ion batteries could be caused by particle contamination in the case or short circuits due to miswinding, which could result in fires.

The thin organic materials that can easily pass X-rays are used in the positive and negative electrodes or separators of the lithium-ion batteries. Accordingly, X-ray cameras with a wide dynamic range are needed for clear observation.

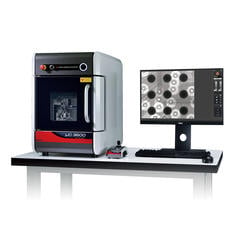

Matsusada Precision's X-ray inspection systems available in benchtop and stationary types employ the high-resolution Flat Panel Detector (FPD) with a 14-bit density resolution, enabling clear observation of the inside of battery cases.

As for the observation of foreign matters at the size of several tens of micrometers, film surface edge, the image magnification of more than 100 times is required. Our microfocus X-ray tubes with a minimum focal spot size of 4 µm can be used for defect analysis because images are not blurred even when observed under magnification.

Matsusada Precision offers X-ray inspection systems of the horizontal irradiation type, ideal for the observation of cylindrical lithium-ion batteries, and X-ray inspection systems of the vertical observation type, suitable for the inspection of lithium polymer batteries and square-shaped batteries. In addition, we offer micro X-ray CT scanners for investigation and analysis, as well as industrial X-ray systems used for process inspection in manufacturing plants. Electrolytic capacitors have the same structure and can be used in the same way.

| Focal spot | Microfocus |

|---|---|

| X-ray tube voltage | 90 to 130 kV |

| Magnification | 1 to 100x |