Lithium-ion batteries (LIBs), including LFP and NMC types, consist of alternating layers of cathodes, anodes, and separators housed within a compact case. X-ray inspection is critical for verifying battery quality, as non-visible internal defects can lead to serious safety hazards. Issues such as particle contamination or improper electrode winding can cause internal short circuits, potentially resulting in thermal runaway or fires.

High-Contrast Imaging for Low-Density Materials

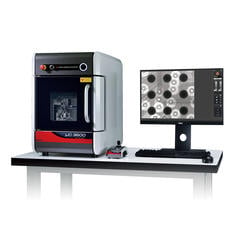

The positive and negative electrodes and separators in LIBs are composed of thin, low-density organic materials that are highly transparent to X-rays. Consequently, a high-dynamic-range detector is required to capture clear contrast. Matsusada Precision's benchtop and stationary X-ray inspection systems feature high-resolution Flat Panel Detectors (FPD) with 14-bit grayscale depth, enabling detailed visualization of the battery's internal structure and material density differences.

Microfocus Technology for Micron-Scale Defects

Detecting foreign matter in the micron range or identifying defects on the edges of electrode films requires geometric magnification exceeding 100x. Our systems utilize microfocus X-ray sources with a minimum focal spot size of 4 µm. This technology ensures sharp, high-definition images even at high magnification, making it an ideal choice for detailed failure analysis and R&D.

Versatile Configurations for Various Cell Types

Matsusada Precision provides both horizontal and vertical X-ray inspection configurations to suit different battery form factors. The horizontal projection systems are optimized for inspecting cylindrical cells, while vertical systems are ideal for pouch and prismatic cells. Additionally, we offer micro-CT scanners for comprehensive 3D analysis and in-line X-ray systems for automated process control. These solutions are also highly effective for inspecting electrolytic capacitors, which share a similar internal wound structure.

| Focal Spot Size | Microfocus |

|---|---|

| X-ray Tube Voltage | 90 to 130 kV |

| Geometric Magnification | 1 to 100x |