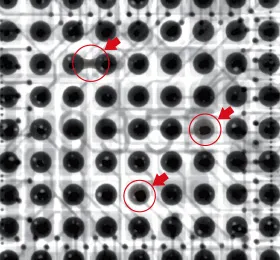

BGA stands for Ball Grid Array and is a semiconductor IC package with solder balls called bumps array on its bottom surface. When mounted on a printed Printed circuit board (PCB), solder paste is printed on the joints of the Printed circuit board (PCB), called lands, and the BGA is mounted and heated for bonding. Due to their shape, optical and appearance inspections cannot detect solder bridge or shorted failures due to the BGA's shapes.

Matsusada Precision provides X-ray Non-Destructive Testing solutions used in joint condition inspection of BGA and PCB.

| Focal spot | Less than 100µm (mini-focus) |

|---|---|

| X-ray tube voltage | 60 to 90 kV |

| Magnification | 1 to 10x |