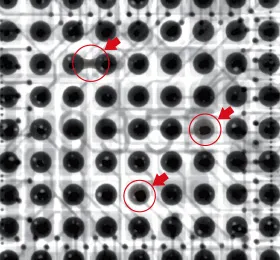

A Ball Grid Array (BGA) is a type of surface-mount packaging for integrated circuits that utilizes a grid of solder balls, or "bumps," on its underside to conduct electrical signals. During assembly, the BGA is placed on PCB pads (lands) with solder paste and heated to form connections. Because these solder joints are hidden beneath the package, standard visual or optical inspections cannot detect internal defects such as solder bridges, shorts, or voids.

Matsusada Precision offers advanced non-destructive X-ray inspection systems designed to verify the quality of BGA solder connections efficiently.

| Focal Spot | Less than 100µm (mini-focus) |

|---|---|

| X-ray Tube Voltage | 60 to 90 kV |

| Magnification | 1 to 10x |