Types of Motor for EV

With the support of the government, many European countries, the United States, and China are advancing the transition from conventional automobiles to electric vehicles. In Japan, companies such as Toyota, Nissan, and Mitsubishi Motors are at the forefront of developing electric vehicles (EVs) rapidly. An EV is powered by a battery and a motor instead of a gasoline engine. Each manufacturer makes a different version of this motor. Everyone is aware, I believe, that Nissan has already sold LEAF Electric vehicles, etc.

The two main categories of motors are DC motors and AC motors that operate on DC and AC power supplies, respectively. DC motors can be further categorized into brushed DC motors and stepper motors. Brushless motors, a subcategory of AC motors, consist of a rotor that rotates during the passage of a current and a stator that rotates the rotor. Based on this, we introduce the features of each of the aforementioned motors.

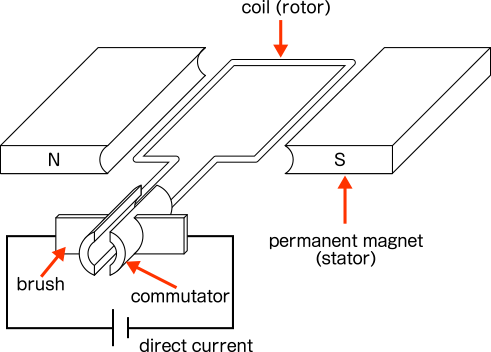

We will start with the brushed DC motor. The brushed DC motor uses coils (electromagnets) for the rotor and permanent magnets for the stator (Fig. 1). As the rotor rotates, the magnetic field changes automatically, and it will continue to rotate semi-permanently as long as the current flows. Owing to the simplicity of the structure, the system is inexpensive. However, the disadvantages of the brushed DC motor include the need for a brush at the commutator in contact with the power supply, which can cause friction noise and brush wear.

Fig. 1 Schematic of a brushed DC motor

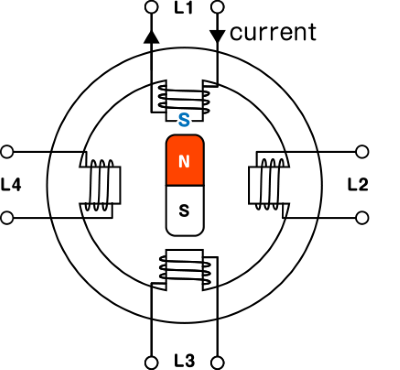

Conversely, a stepper motor uses a permanent magnet for the rotor and an electromagnet for the stator, as opposed to a brushed DC motor. Multiple electromagnets are placed on the stator and only one of them is turned on (Fig. 2).

Fig. 2 Working principle of a stepper motor:

(a) first electromagnet switched on;

(b) first electromagnet switched off and second electromagnet switched on

As the rotor approaches the electromagnet in response to the magnetic poles of the rotor, the electromagnet is switched off and the electromagnet ahead of the rotation is turned on. Repeating this, the rotor keeps rotating, and the rotation speed is controlled. However, many electromagnets are required for smooth control, and switching control becomes difficult.

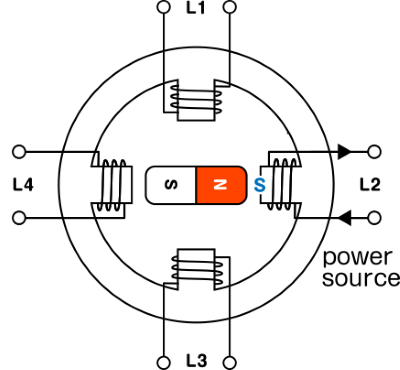

To prevent these drawbacks, brushless motors are utilized in EVs (Fig. 3). They operate on a three-phase AC power supply, and in contrast to a brush motor, the rotor is a permanent magnet, and the stator is an electromagnet.

Fig. 3 Schematic of a brushless motor. U: U-phase winding; V: V-phase winding; W: W-phase winding; rotor: magnet

Brushless motors are noise-less and there is no brush wear; moreover, controlling the electromagnet will be easy. However, a mechanism to control the electromagnet as the stator is required and should be powered by a three-phase AC power source. In particular, to detect and apply an alternating current based on the rotational speed of the rotor, a rotational position sensor is required.

In the case of EV, controlling the flow of alternating current depending on the amount of accelerator pedal depression and the rotational speed of the rotor is also important, necessitating the use of an accelerator position sensor. Based on the values from these sensors, the ECU (electronic control unit) adjusts the frequency and amount of current to obtain the appropriate values for rotation speed, torque, and other such parameters.

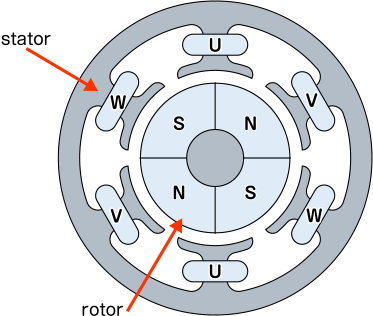

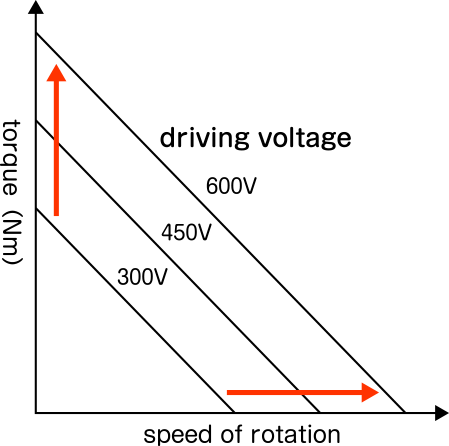

Fig. 4 Relationship between drive voltage and torque

Furthermore, the higher the drive voltage, the greater the torque and the faster the rotor rotates (Fig. 4). Auto manufacturers are striving to increase the starting voltage.

Requirements for EV Power Supply

There are various factors that determine the power supply of an EV motor. They are essentially divided into four categories: voltage, electrical capacity, characteristics, and safety.

Lithium-ion batteries are the mainstream battery cells for EVs, although they only provide 3.6 V per cell. Normally, a 7.2 V cell is used as one module, and four modules are connected in series and parallel. Depending on the manufacturer, these modules are connected in series and used to provide voltages such as 280 V or 360 V . For instance, a permanent neodymium magnet embedded three-phase AC synchronous motor, EM61, is operated at a drive voltage of 345 V and used in the EV, Nissan Leaf.

The second category is the electrical capacity. This is important because the cruising distance will increase if the electrical capacity is high. The October 2017 Leaf model has a capacity of 40 kWh and an EPA coverage of 241 km. Worldwide, BMW's i3 has a capacity of 33 kWh and EPA coverage of 182 km. The top manufacturer of EVs is Tesla Motors. The electrical capacity of their Model S varies from 60 to 100 kWh and supports 110, 220, and 440 V chargeable voltages (Table 1).

Table 1 Electric capacities of various EV models

| Automobile manufacturer | Type of vehicle | Type | EV driving mode (JC08) |

EV driving mode (EPA) |

Capacity of a battery | Quick charge |

|---|---|---|---|---|---|---|

| BMW | i3 (94 Ah) | BEV | 390 | 182 | 33 | Yes |

| Honda | FitEV (end of life at 03/2016) |

BEV | 225 | 131 | 20 | Yes |

| Mitsubishi | i-MiEV X | BEV | 180 | 99 | 16 | Yes |

| Mitsubishi | i-MiEV M | BEV | 120 | 66 (undisclosed) |

10.5 | Yes |

| Nissan | Leaf, New Model (40 kWh) | BEV | 400 | 241 | 40 | Yes |

| Nissan | Leaf, Old Model (30 kWh) | BEV | 280 | 171 | 30 | Yes |

| Tesla | Model S 75 | BEV | (undisclosed) | 398.4 | 75 | Yes |

| Tesla | Model S P100D | BEV | (undisclosed) | 504 | 100 | Yes |

| Tesla | Model X 75D | BEV | (undisclosed) | 380.8 | 75 | Yes |

| Tesla | Model X P100D | BEV | (undisclosed) | 462.4 | 100 | Yes |

| Volkswagen | e-Golf | BEV | 301 | 201 | 35.8 | Yes |

Third, lithium-ion batteries have specific electrical characteristics based on temperature. The temperature rises due to charge and discharge, and the output voltage decreases when the temperature exceeds 70 ℃. Moreover, the internal resistance increases when the temperature falls below -30 ℃.

Finally, there are also safety concerns. Liquid leakage may occur due to the use of electrolytes. Precautionary measures against leaks in the module are critical to prevent problems while driving.

In addition, because the vehicle needs to be safe in the event of a collision, a level that does not leak even in normal conditions is required, resulting in increased weight and cost of the vehicle. The voltage required in determining if there is a leakage is high in comparison to the 100 V required for household use. The 12 V battery installed in a gasoline vehicle makes the comparison with EV difficult. EV is a collective entity of parts of various voltages ranging from motors that require high voltage, and those requiring low voltage. Consequently, safety tests should also be performed with power supplies that support various voltages.

Related Technical Articles

Recommended products

Engineers working on inverters and batteries for EV motors select Matsusada Precision's power supply equipment for evaluation and testing.

Reference (Japanese site)

- Japanese source page 「電池業界が熱い! EV用モーターの電源電圧」

https://www.matsusada.co.jp/column/ev-power.html - 電気自動車に使われるモーターの種類と仕組み

https://allabout.co.jp/gm/gc/423947/ - 世界が注目するEVモーターの高効率化原理について考えてみよう

https://edn.itmedia.co.jp/edn/articles/1805/22/news006.html - いまさら聞けない 電装部品入門(11)

https://monoist.itmedia.co.jp/mn/articles/1401/16/news007.html - ステッピングモーターの基礎

https://www.orientalmotor.co.jp/tech/webseminar/stkiso_2_1_1/ - スピードコントロールモーター/ブラシレスモーター

https://www.orientalmotor.co.jp/tech/reference/brushless01/ - 日産リーフ分解調査(その2)

https://www.marklines.com/ja/report_all/rep1104_201209 - 電気自動車のメーカー別一覧

https://blog.evsmart.net/electric-vehicles/ev-phev-list/ - EVの課題克服?リチウムイオン電池の後釜

https://business.nikkei.com/atcl/report/15/226265/051700123/